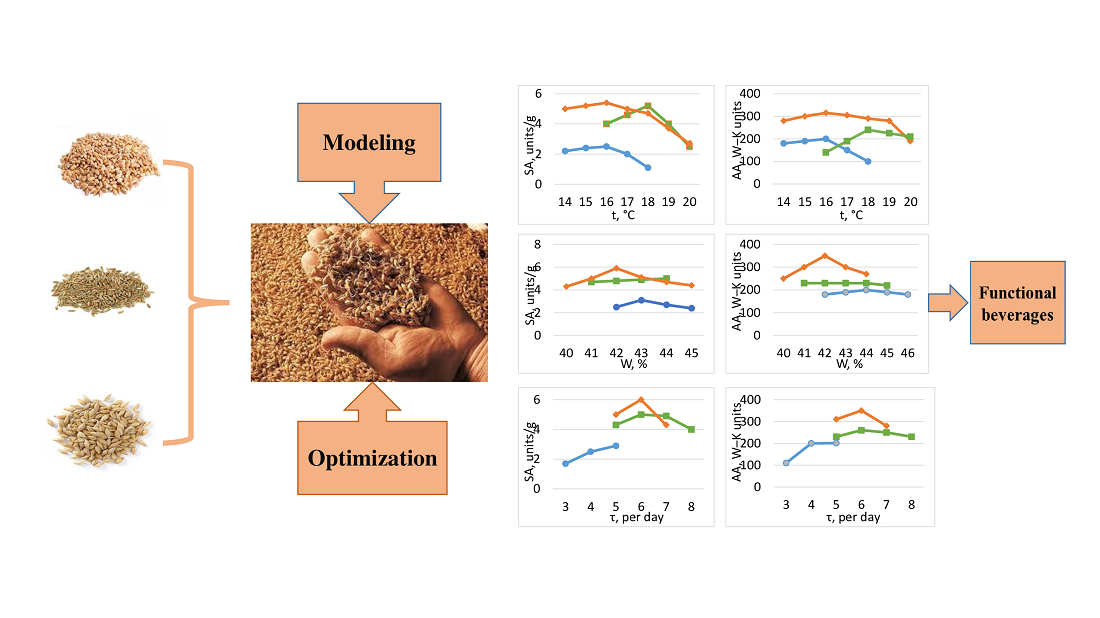

Розробка моделі та оптимізація взаємодії факторів у процесі солодування зерна та її застосування у виробництві функціональних напоїв

DOI:

https://doi.org/10.15587/1729-4061.2023.289421Ключові слова:

зерно, солодування, моделювання, оптимізація, амілолітична активність, цукроутворююча активність, функціональні напоїАнотація

Робота присвячена вивченню взаємодії та значущості факторів, що впливають на прогнозування та оптимізацію процесу одержання солоду. Об'єктом дослідження є пшеничний, ячмінний та житній солод. Було проведено 33 повних факторних експерименти, в якості змінних факторів виступали період проростання, ступінь змочування і температура. При цьому в якості функції відгуку експерименту взяті амілолітична активність ферментного комплексу солоду та його цукроутворюючу здатність. Для перевірки правильності вибору оптимальних умов процесу одержання солоду було проведено 27 експериментів у триразовій повторності та отримано рівняння регресії. Відповідно до методу найменших квадратів отримані рівняння регресії для апроксимації значень цукроутворюючої здатності (SA) та амілолітичної активності (AA) пшеничного солоду. Згідно з методом регресійного аналізу, адекватність рівнянь перевірялася за критерієм Фішера, статистична значимість їх коефіцієнтів – за критерієм Стьюдента, однорідність паралельних експериментів – за критерієм Кохрена. Регресійна модель, що виражає результат оптимізації процесу одержання пшеничного солоду, виглядає наступним чином: τ=5,8 доби, w=42,2 %, t=15,9 °C; YSA=5,35, YAA=320,0, для ячмінного солоду – τ=6,1 доби; w=44,1 %; t=17,6 °C; YSA=4,93; YAA=255,2, для житнього солоду – τ=4,6 доби; w=45,1 %; t=15,0 °C; YSA=8,63; YAA=198,1. У даній роботі також вивчалася залежність амілолітичної та цукроутворюючої активності солодових ферментів від температури. Температура проростання зерен має максимальний вплив на комплекс амілолітичних ферментів солоду.

Матеріали дослідження можуть бути використані при виробництві безалкогольних та функціональних напоїв

Посилання

- Patra, M., Bashir, O., Amin, T., Wani, A. W., Shams, R., Chaudhary, K. S. et al. (2023). A comprehensive review on functional beverages from cereal grains-characterization of nutraceutical potential, processing technologies and product types. Heliyon, 9 (6), e16804. doi: https://doi.org/10.1016/j.heliyon.2023.e16804

- Almaguer, C., Kollmannsberger, H., Gastl, M., Becker, T. (2023). Comparative study of the impact of malting on the aroma profiles of barley (Hordeum vulgare L.) and rye (Secale cereale L.). Food Chemistry, 427, 136694. doi: https://doi.org/10.1016/j.foodchem.2023.136694

- Panigrahi, C., Mishra, H. N., De, S. (2022). Ozone treatment of ultrafiltered sugarcane juice: Process optimization using multi-objective genetic algorithm and correlation analysis by multivariate technique. LWT, 154, 112861. doi: https://doi.org/10.1016/j.lwt.2021.112861

- Calvi, A., Preiti, G., Gastl, M., Poiana, M., Zarnkow, M. (2023). Malting process optimization of an Italian common wheat landrace (Triticum aestivum L.) through response surface methodology and desirability approach. LWT, 173, 114242. doi: https://doi.org/10.1016/j.lwt.2022.114242

- Muñoz-Insa, A., Selciano, H., Zarnkow, M., Becker, T., Gastl, M. (2013). Malting process optimization of spelt (Triticum spelta L.) for the brewing process. LWT - Food Science and Technology, 50 (1), 99–109. doi: https://doi.org/10.1016/j.lwt.2012.06.019

- Tene, S. T., Ndinteh, D. T., Dongmo, J. R., Adebo, O. A., Kewuyemi, Y. O., Kengne Kamdem, M. H. et al. (2022). Optimization using response surface methodology of amylolytic capacity of maize Atp-Y and coca-sr varieties: In vitro digestibility capacity, physico-chemical and functional properties of optimal sample. Journal of Agriculture and Food Research, 9, 100342. doi: https://doi.org/10.1016/j.jafr.2022.100342

- Soares, M. A. B., Jorge, L. M. De M., Montanuci, F. D. (2016). Drying kinetics of barley grains and effects on the germination index. Food Science and Technology, 36 (4), 638–645. doi: https://doi.org/10.1590/1678-457x.11916

- Kaur, K. T., Kaur, J. T., Kaur, A. T. (2021). Current Trends in Multigrain Foods for Healthcare. Cereals and Cereal-Based Foods, 83–99. doi: https://doi.org/10.1201/9781003081975-7

- Gadimova, N., Fataliyev, H., Allahverdiyeva, Z., Musayev, T., Akhundova, N., Babashli, A. (2022). Obtaining and investigation of the chemical composition of powdered malt and polymalt extracts for application in the production of non-alcoholic functional beverages. Eastern-European Journal of Enterprise Technologies, 5 (11 (119)), 66–74. doi: https://doi.org/10.15587/1729-4061.2022.265762

- Thakur, A., Pandey, P., Dalbhagat, C. G., Mishra, H. N. (2021). Development of grain-based carbonated beverage premix using maize (Zea Mays), Bengal gram (Cicer Arietinum), and finger millet (Eleusine Coracana). Journal of Food Science and Technology, 59 (4), 1637–1648. doi: https://doi.org/10.1007/s13197-021-05175-5

- Estevão, S. T., Batista de Almeida e Silva, J., Lourenço, F. R. (2021). Development and optimization of beer containing malted and non-malted substitutes using quality by design (QbD) approach. Journal of Food Engineering, 289, 110182. doi: https://doi.org/10.1016/j.jfoodeng.2020.110182

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Natavan Gadimova, Hasil Fataliyev, Elnur Heydarov, Yusif Lezgiyev, Simuzar Isgandarova

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.