Development of buckwheat groats production technology using plasma-chemically activated aqueous solutions

DOI:

https://doi.org/10.15587/1729-4061.2023.290584Keywords:

plasma-chemical activation, aqueous solutions, hydrothermal treatment, buckwheat groats, amino acids, disinfectantAbstract

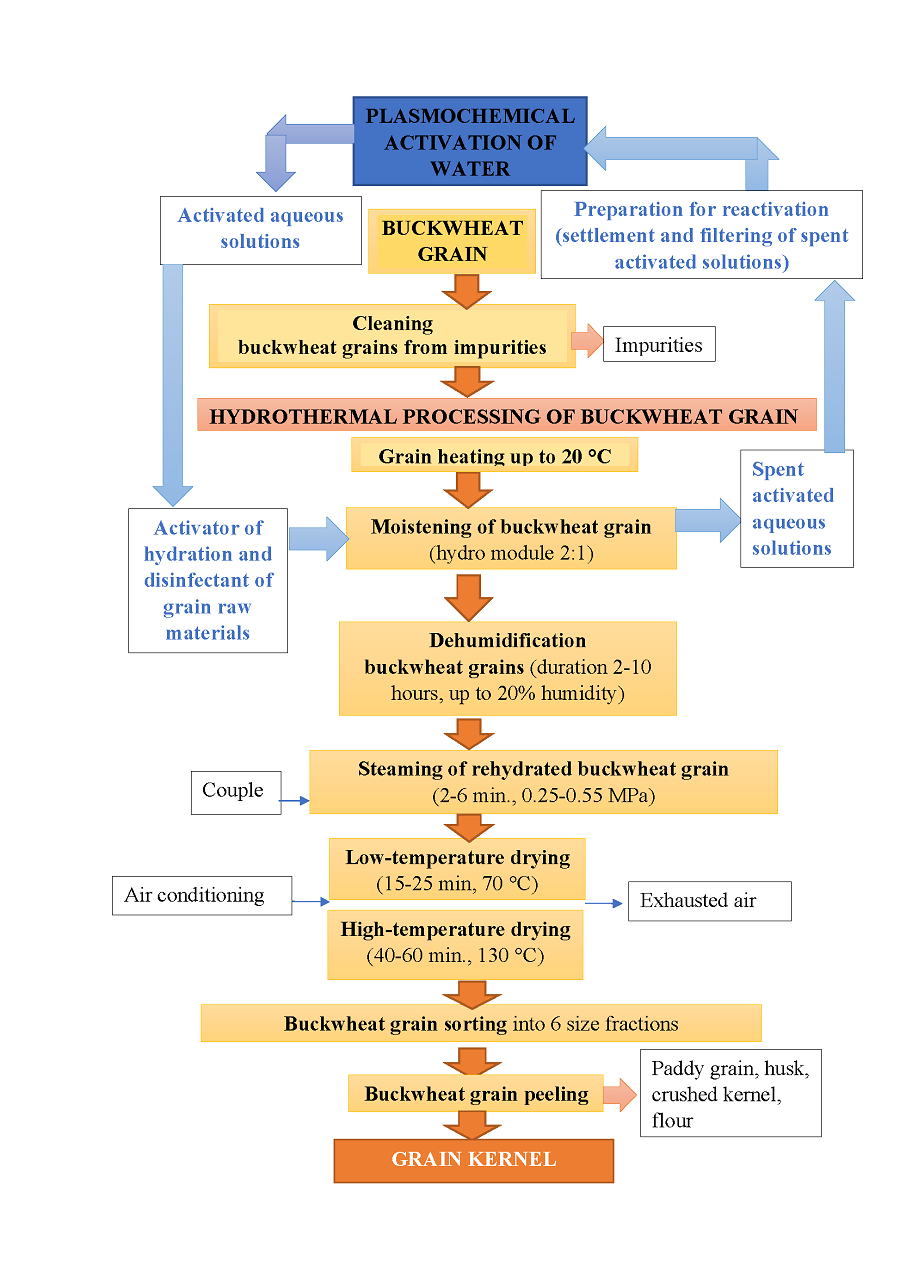

The result of the conducted research is the development of a technology for the production of buckwheat groats using plasma-chemically activated aqueous solutions. The research object was buckwheat grain. An urgent technological problem is the preservation of biologically valuable components of buckwheat during technological operations and optimization of the existing technology for the production of buckwheat groats. The expediency of using plasma-chemically activated aqueous solutions as an intensifier of the technological process of production of buckwheat groats and an effective groats disinfectant has been experimentally proven. It is shown that the use of plasma-chemical activation of technological solutions allows reducing the temperature and accelerating the course of hydrothermal treatment of buckwheat grain. The composition of buckwheat grain as a raw material was analyzed. The obtained buckwheat groats were studied separately. A reduction in tempering time from 6–10 to 2 h and a decrease in the optimal moistening temperature from 60 to 40 °C were recorded. This allows preserving a number of biologically important components in buckwheat grain. The groats yield increases from 68 to 74 %, i.e. by 1.9–6.0 %. The preservation of the maximum number of amino acids is observed, namely, 7.7 % more than in the control. That is, only 2 % is lost during technological processing, instead of 9.7 % in the control sample. The vitamin composition also remains stable and almost does not decrease in terms of B1, B2, B3, B4, B5, B6, K, E, PP, R. In addition, plasma-chemically activated solutions qualitatively disinfect grain raw materials during processing, which has a positive effect on further storage of buckwheat groats.

The technology can be applied in the industrial production of high-quality buckwheat groats. The developed technology will receive special attention in the production of ecologically clean cereal products that are not contaminated with pathogenic microflora

References

- Kim, S. J., Sohn, H. B., Suh, J. T., Kim, G. H., Hong, S. Y., Chang, D. C. et al. (2017). Domestic and Overseas Status of Buckwheat Production and Future Trends. Journal of the Korean Society of International Agricultue, 29 (3), 226–233. doi: https://doi.org/10.12719/ksia.2017.29.3.226

- Lu, L., Murphy, K., Baik, B. (2013). Genotypic Variation in Nutritional Composition of Buckwheat Groats and Husks. Cereal Chemistry, 90 (2), 132–137. doi: https://doi.org/10.1094/cchem-07-12-0090-r

- Suvorova, G Zhou, M. (2018). Distribution of Cultivated Buckwheat Resources in the World. Buckwheat Germplasm in the World, 21–35. doi: https://doi.org/10.1016/b978-0-12-811006-5.00003-3

- Vombergar, B., Tašner, L., Horvat, M., Vorih, S., Pem, N., Golob, S., Kovač, T. (2022). Buckwheat – Challenges in nutrition and technology / Ajda – izzivi v tehnologiji in prehrani. Fagopyrum, 39 (2), 33–42. doi: https://doi.org/10.3986/fag0026

- Gong, X., An, Q., Le, L., Geng, F., Jiang, L., Yan, J. et al. (2020). Prospects of cereal protein-derived bioactive peptides: Sources, bioactivities diversity, and production. Critical Reviews in Food Science and Nutrition, 62 (11), 2855–2871. doi: https://doi.org/10.1080/10408398.2020.1860897

- Wijngaard, H. H., Arendt, E. K. (2006). Buckwheat. Cereal Chemistry, 83 (4), 391–401. doi: https://doi.org/10.1094/cc-83-0391

- Ikeda, K. (2002). Buckwheat composition, chemistry, and processing. Advances in Food and Nutrition Research, 395–434. doi: https://doi.org/10.1016/s1043-4526(02)44008-9

- Giménez-Bastida, J., Piskuła, M., Zieliński, H. (2015). Recent Advances in Processing and Development of Buckwheat Derived Bakery and Non-Bakery Products – a Review. Polish Journal of Food and Nutrition Sciences, 65 (1), 9–20. doi: https://doi.org/10.1515/pjfns-2015-0005

- Vasylieva, N. (2017). Economic Aspects of Food Security in Ukrainian Meat and Milk Clusters. Agris On-Line Papers in Economics and Informatics, 9 (3), 81–92. doi: https://doi.org/10.7160/aol.2017.090308

- Kovalova, O. S. (2022). Innovatsiyna tekhnolohiya vyrobnytstva hrechanoi krupy. The 14th International scientific and practical conference “Modern stages of scientific research development”. Prague, 453–460. Available at: https://isg-konf.com/wp-content/uploads/2022/12/Modern-stages-of-scientific-research-development.pdf

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. doi: https://doi.org/10.15587/1729-4061.2020.200026

- Zhygynov, D. A., Soc, S. M., Drozdov, A. Y. (2016). Production and quality of buckwheat products. Grain Products and Mixed Fodder’s, 64 (4), 22–25. doi: https://doi.org/10.15673/gpmf.v64i4.263

- Worobiej, E., Piecyk, M., Perzyna, G., Turos, J. (2017). Effect of processing and thermally treating buckwheat grains on nutrients. Zywnosc Nauka Technologia Jakosc/Food Science Technology Quality, 24, 60–73. doi: https://doi.org/10.15193/zntj/2017/112/198

- Chen, X.-W., Luo, D.-Y., Chen, Y.-J., Wang, J.-M., Guo, J., Yang, X.-Q. (2019). Dry fractionation of surface abrasion for polyphenol-enriched buckwheat protein combined with hydrothermal treatment. Food Chemistry, 285, 414–422. doi: https://doi.org/10.1016/j.foodchem.2019.01.182

- Plumier, B., Kenar, J. A., Felker, F. C., Winkler‐Moser, J., Singh, M., Byars, J. A., Liu, S. X. (2023). Effect of subcritical water flash release processing on buckwheat flour properties. Journal of the Science of Food and Agriculture, 103 (4), 2088–2097. doi: https://doi.org/10.1002/jsfa.12399

- Luthar, Z., Golob, A., Germ, M., Vombergar, B., Kreft, I. (2021). Tartary Buckwheat in Human Nutrition. Plants, 10 (4), 700. doi: https://doi.org/10.3390/plants10040700

- Christa, K., Soral-Śmietana, M. (2008). Buckwheat grains and buckwheat products - nutritional and prophylactic value of their components - a review. Czech Journal of Food Sciences, 26 (3), 153–162. doi: https://doi.org/10.17221/1602-cjfs

- Dmitriev, A., Ziganshin, B., Khaliullin, D., Aleshkin, A. (2020). Study of efficiency of peeling machine with variable deck. Engineering for Rural Development. doi: https://doi.org/10.22616/erdev.2020.19.tf249

- Kreft, I., Golob, A., Vombergar, B., Germ, M. (2023). Tartary Buckwheat Grain as a Source of Bioactive Compounds in Husked Groats. Plants, 12 (5), 1122. doi: https://doi.org/10.3390/plants12051122

- Germ, M., Árvay, J., Vollmannová, A., Tóth, T., Kreft, I., Golob, A. (2020). Hydrothermal Treatments Affecting the Concentration of Neochlorogenic Acid in Dough of Tartary Buckwheat. Agriculture, 10 (12), 601. doi: https://doi.org/10.3390/agriculture10120601

- Lukšič, L., Árvay, J., Vollmannová, A., Tóth, T., Škrabanja, V., Trček, J. et al. (2016). Hydrothermal treatment of Tartary buckwheat grain hinders the transformation of rutin to quercetin. Journal of Cereal Science, 72, 131–134. doi: https://doi.org/10.1016/j.jcs.2016.10.009

- Oh, M., Oh, I., Jeong, S., Lee, S. (2019). Optical, rheological, thermal, and microstructural elucidation of rutin enrichment in Tartary buckwheat flour by hydrothermal treatments. Food Chemistry, 300, 125193. doi: https://doi.org/10.1016/j.foodchem.2019.125193

- Filipiak-Florkiewicz, A., Florkiewicz, A. (2016). Effect of hydrothermal treatment on content of nutrients and bioactive components in groats and rice. Zywnosc. Nauka. Technologia. Jakosc/Food. Science Technology. Quality, 6. Available at: http://journal.pttz.org/wp-content/uploads/2017/03/06_Filipiak-Florkiewicz.pdf

- Zieliński, H., Achremowicz, B., Przygodzka, M. (2012). Antioxidants in cereal grains. Zywnosc.Nauka.Technologia.Jakosc/Food.Science.Technology.Quality. doi: https://doi.org/10.15193/zntj/2012/80/005-026

- Zielinska, D., Szawara-Nowak, D., Zielinski, H. (2007). Comparison of Spectrophotometric and Electrochemical Methods for the Evaluation of the Antioxidant Capacity of Buckwheat Products after Hydrothermal Treatment. Journal of Agricultural and Food Chemistry, 55 (15), 6124–6131. doi: https://doi.org/10.1021/jf071046f

- Skrabanja, V., Lærke, H. N., Kreft, I. (2000). Protein-polyphenol interactions and in vivo digestibility of buckwheat groat proteins. Pflügers Archiv - European Journal of Physiology, 440 (S1), R129–R131. doi: https://doi.org/10.1007/s004240000033

- Liu, X., Wang, L., Li, C., Li, X., Kumrungsee, T., Zhai, X., Zhou, Z., Cao, R. (2023). The modification of buckwheat polyphenols by different pretreatments and complexation, and its application in oat flour model. Food Bioscience, 56, 103133. doi: https://doi.org/10.1016/j.fbio.2023.103133

- Roy, M., Dutta, H., Jaganmohan, R., Choudhury, M., Kumar, N., Kumar, A. (2019). Effect of steam parboiling and hot soaking treatments on milling yield, physical, physicochemical, bioactive and digestibility properties of buckwheat (Fagopyrum esculentum L.). Journal of Food Science and Technology, 56 (7), 3524–3533. doi: https://doi.org/10.1007/s13197-019-03849-9

- Liu, H., Lv, M., Peng, Q., Shan, F., Wang, M. (2015). Physicochemical and textural properties of tartary buckwheat starch after heat–moisture treatment at different moisture levels. Starch - Stärke, 67 (3-4), 276–284. doi: https://doi.org/10.1002/star.201400143

- Sindhu, R., Devi, A., Khatkar, B. S. (2019). Physicochemical, thermal and structural properties of heat moisture treated common buckwheat starches. Journal of Food Science and Technology, 56 (5), 2480–2489. doi: https://doi.org/10.1007/s13197-019-03725-6

- Liu, H., Guo, X., Li, W., Wang, X., lv, M., Peng, Q., Wang, M. (2015). Changes in physicochemical properties and in vitro digestibility of common buckwheat starch by heat-moisture treatment and annealing. Carbohydrate Polymers, 132, 237–244. doi: https://doi.org/10.1016/j.carbpol.2015.06.071

- Amudha Senthil, S. P. (2015). Effect of Hydrothermal Treatment on the Nutritional and Functional Properties of Husked and Dehusked Buckwheat. Journal of Food Processing & Technology, 06 (07). doi: https://doi.org/10.4172/2157-7110.1000461

- Collar, C. (2017). Significance of heat-moisture treatment conditions on the pasting and gelling behaviour of various starch-rich cereal and pseudocereal flours. Food Science and Technology International, 23 (7), 623–636. doi: https://doi.org/10.1177/1082013217714671

- Vicente, A., Villanueva, M., Caballero, P. A., Muñoz, J. M., Ronda, F. (2023). Buckwheat grains treated with microwave radiation: Impact on the techno-functional, thermal, structural, and rheological properties of flour. Food Hydrocolloids, 137, 108328. doi: https://doi.org/10.1016/j.foodhyd.2022.108328

- Yuan, Y., Shimizu, N., Li, F., Magaña, J., Li, X. (2023). Buckwheat waste depolymerization using a subcritical ethanol solution for extraction of bioactive components: from the laboratory to pilot scale. Journal of Environmental Chemical Engineering, 11 (3), 109807. doi: https://doi.org/10.1016/j.jece.2023.109807

- Kovaliova, O., Pivovarov, O., Koshulko, V. (2020). Study of hydrothermal treatment of dried malt with plasmochemically activated aqueous solutions. Food Science and Technology, 14 (3). doi: https://doi.org/10.15673/fst.v14i3.1799

- Kovaliova, O., Pivovarov, O., Kalyna, V., Tchoursinov, Y., Kunitsia, E., Chernukha, A. et al. (2020). Implementation of the plasmochemical activation of technological solutions in the process of ecologization of malt production. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 26–35. doi: https://doi.org/10.15587/1729-4061.2020.215160

- Pivovarov, O., Kovaliova, O., Koshulko, V. (2020). Effect of plasmochemically activated aqueous solution on process of food sprouts production. Ukrainian Food Journal, 9 (3), 576–587. doi: https://doi.org/10.24263/2304-974x-2020-9-3-7

- Pivovarov, О., Kovalova, О., Koshulko, V., Aleksandrova, A. (2022). Study of use of antiseptic ice of plasma-chemically activated aqueous solutions for the storage of food raw materials. Food Science and Technology, 15 (4). doi: https://doi.org/10.15673/fst.v15i4.2260

- Pivovarov, О., Kovalova, О., Koshulko, V. (2022). Disinfection of marketable eggs by plasma-chemically activated aqueous solutions. Food Science and Technology, 16 (1). doi: https://doi.org/10.15673/fst.v16i1.2289

- Pivovarov, О., Kovaliova, О., Koshulko, V. (2022). Effect of plasma-chemically activated aqueous solutions on the process of disinfection of food production equipment. Food Science and Technology, 16 (3). doi: https://doi.org/10.15673/fst.v16i3.2392

- Kovaliova, О., Pivovarov, О., Vasylieva, N., Koshulko, V. (2023). Obtaining of rice malt with the use of plasma-chemically activated aqueous solutions. Food science and technology, 16 (4). doi: https://doi.org/10.15673/fst.v16i4.2542

- Kovalova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Haliasnyi, I., Gontar, T. et al. (2023). Determining the effect of plasmochemically activated aqueous solutions on the bioactivation process of sea buckthorn seeds. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 99–111. doi: https://doi.org/10.15587/1729-4061.2023.275548

- Kovaliova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Mandych, O., Hontar, T. et al. (2023). Development of a technology for the production of germinated flaxseed using plasma-chemically activated aqueous solutions. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 6–19. doi: https://doi.org/10.15587/1729-4061.2023.284810

- Greene, W. (2003). Econometric Analysis. Prentice Hall, 1026. Available at: http://surl.li/mcvrp

- Pivovarov, O., Kovaliova, O. (2019). Features of grain germination with the use of aqueous solutions of fruit acids. Food Science and Technology, 13 (1). doi: https://doi.org/10.15673/fst.v13i1.1334

- Pivovarov, O., Kovaliova, O., Khromenko, T., Shuliakevych, Z. (2017). Features of obtaining malt with use of aqueous solutions of organic acids. Food Science and Technology, 11 (4). doi: https://doi.org/10.15673/fst.v11i4.728

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Olena Kovaliova, Natalia Vasylieva, Ivan Haliasnyi, Tatiana Gavrish, Aliona Dikhtyar, Svitlana Andrieieva, Nataliia Didukh, Iryna Balandina, Larysa Obolentseva, Nataliia Hirenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.