Доведення можливості раціоналізації процесу сепарації насіннєвих матеріалів вібропневмовідцентровим сепаратором з використанням теоретичної моделі

DOI:

https://doi.org/10.15587/1729-4061.2023.291114Ключові слова:

вібропневмовідцентровий сепаратор, густина насіннєвого матеріалу, багатофазне середовище, псевдорідина, параметри сепаруванняАнотація

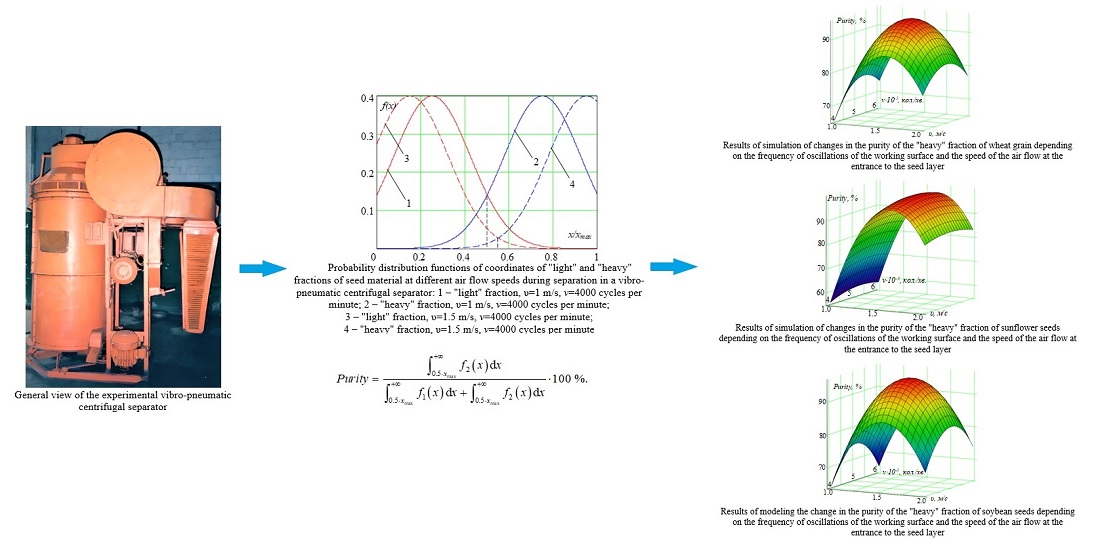

Об’єктом досліджень є насіннєвий матеріал та робочі органи вібропневмовідцентрового сепаратора, предметом – їх взаємодія. Встановлені поверхні, які є результатами моделювання процесу сепарування насіннєвих матеріалів у вібропневмовідцентровому сепараторі, мають вигин до площини, параметрами якої є швидкість повітряного потоку та частота коливань робочої поверхні. Відзначено, що такий характер залежності чистоти «важкої» фракції насіння від параметрів процесу сепарування надає можливість визначати раціональні діапазони цих параметрів, за яких досягається максимальне значення цієї характеристики. Експериментальним моделюванням у виробничих умовах процесу сепарування у вібропневмовідцентровому сепараторі насіннєвих матеріалів пшениці, соняшника та сої встановлено високу збіжність результатів з результатами моделювання процесу за тих же вихідних умов. Встановлено, що коефіцієнти кореляції між точками, отриманими експериментально та отриманими моделюванням, для наведених результатів знаходяться в межах від 0.89 до 0.95. При цьому відмінності полягають у значеннях чистоти «важкої» фракції насіння, а не у характері її зміни за зміни параметрів процесу сепарування. Відзначена доцільність застосування моделювання під час визначення раціональних значень параметрів процесу розділення у вібропневмовідцентровому сепараторі. Це сприятиме підвищенню енерго- та ресурсоефективності обладнання через відсутність необхідності експериментального налаштування. Визначені раціональні діапазони швидкості повітряного потоку та частоти коливань ротора вібропневмовідцентрового сепаратора для сепарування насіннєвих матеріалів: пшениці – 1.2…1.5 м/с; 4500…5100 кол./хв; соняшника – 1.3…1.5 м/с; 4500…5000 кол./хв; сої – 1.3…1.6 м/с; 5000…5500 кол./хв.

Посилання

- Stepanenko, S., Aneliak, M., Kuzmych, A., Kustov, S., Lysaniuk, V. (2022). Improving the efficiency of harvesting sunflower seed crops. INMATEH Agricultural Engineering, 67 (2), 331–340. doi: https://doi.org/10.35633/inmateh-67-34

- Stepanenko, S. P. (2017). Research pneumatic gravity separation grain materials. International Scientific Journal "Mechanization in Agriculture", 2, 54–56. Available at: https://stumejournals.com/journals/am/2017/2/54.full.pdf

- Chaplygin, M., Bespalova, O., Podzorova, M. (2019). Results of tests of devices for sunflower harvesting in economic conditions. E3S Web of Conferences, 126, 00063. doi: https://doi.org/10.1051/e3sconf/201912600063

- Jin, W., Ding, Y., Bai, S., Zhang, X., Yan, J., Zhou, X. (2021). Design and experiments of the reel board header device for an oil sunflower harvester. Transactions of the Chinese Society of Agricultural Engineering, 37 (3), 27–36. Available at: http://www.tcsae.org/nygcxben/article/abstract/20210304

- Rogovskii, I. L., Martiniuk, D. I., Voinash, S. A., Luchinovich, A. A., Sokolova, V. A., Ivanov, A. M., Churakov, A. V. (2021). Modeling the throughput capacity of threshing-separating apparatus of grain harvester’s combines. IOP Conference Series: Earth and Environmental Science, 677 (4), 042098. doi: https://doi.org/10.1088/1755-1315/677/4/042098

- Shaforostov, V. D., Makarov, S. S., Elizarov, P. A. (2018). A harvester to a breeding and seeds growing combine for sunflower harvesting. Oil Crops. Scientific and Technical Bulletin of All-Russian Research Institute of Oil Crops by the Name of Pustovoit V.S., 3 (175), 76–80. doi: https://doi.org/10.25230/2412-608x-2018-3-175-76-80

- Bredykhin, V., Gurskyi, P., Alfyorov, O., Bredykhina, K., Pak, A. (2021). Improving the mechanical-mathematical model of grain mass separation in a fluidized bed. Eastern-European Journal of Enterprise Technologies, 3 (1 (111)), 79–86. doi: https://doi.org/10.15587/1729-4061.2021.232017

- Kumar, D., Kalita, P. (2017). Reducing Postharvest Losses during Storage of Grain Crops to Strengthen Food Security in Developing Countries. Foods, 6 (1), 8. doi: https://doi.org/10.3390/foods6010008

- Kharchenko, S., Borshch, Y., Kovalyshyn, S., Piven, M., Abduev, M., Miernik, A. et al. (2021). Modeling of Aerodynamic Separation of Preliminarily Stratified Grain Mixture in Vertical Pneumatic Separation Duct. Applied Sciences, 11 (10), 4383. doi: https://doi.org/10.3390/app11104383

- Bulgakov, V., Nikolaenko, S., Holovach, I., Adamchuk, V., Kiurchev, S., Ivanovs, S., Olt, J. (2020). Theory of grain mixture particle motion during aspiration separation. Agronomy Research, 18 (1), 18–37. Available at: https://dspace.emu.ee/xmlui/handle/10492/5667

- Tishchenko, L., Kharchenko, S., Kharchenko, F., Bredykhin, V., Tsurkan, O. (2016). Identification of a mixture of grain particle velocity through the holes of the vibrating sieves grain separators. Eastern-European Journal of Enterprise Technologies, 2 (7 (80)), 63–69. doi: https://doi.org/10.15587/1729-4061.2016.65920

- Bakum, M. V., Kharchenko, S. O., кovalyshyn, S. Y., Krekot, M. M., Kharchenko, F. M., Shvets, O. P. et al. (2022). Identification of parameters of the separation process of safflower seed material on sieves. Journal of Physics: Conference Series, 2408 (1), 012013. doi: https://doi.org/10.1088/1742-6596/2408/1/012013

- Salemi, E., Tessari, U., Mastrocicco, N. C., Micol. (2010). Improved gravitational grain size separation method. Applied Clay Science, 48 (4), 612–614. doi: https://doi.org/10.1016/j.clay.2010.03.014

- Bredykhin, V., Pak, A., Gurskyi, P., Denisenko, S., Bredykhina, K. (2021). Improving the mechanical-mathematical model of pneumatic vibration centrifugal fractionation of grain materials based on their density. Eastern-European Journal of Enterprise Technologies, 4 (1 (112)), 54–60. doi: https://doi.org/10.15587/1729-4061.2021.236938

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Vadym Bredykhin, Alexey Bogomolov, Liliia Kis-Korkishchenko, Andrey Pak, Alina Pak

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.