Identification of the regularities of the thermohydraulic processes of the cooling system of an experimental device based on a mathematical model

DOI:

https://doi.org/10.15587/1729-4061.2023.292208Keywords:

pulsed reactor with graphite moderator, emergency analysis, heterogeneous processes, mathematical modeling, model verificationAbstract

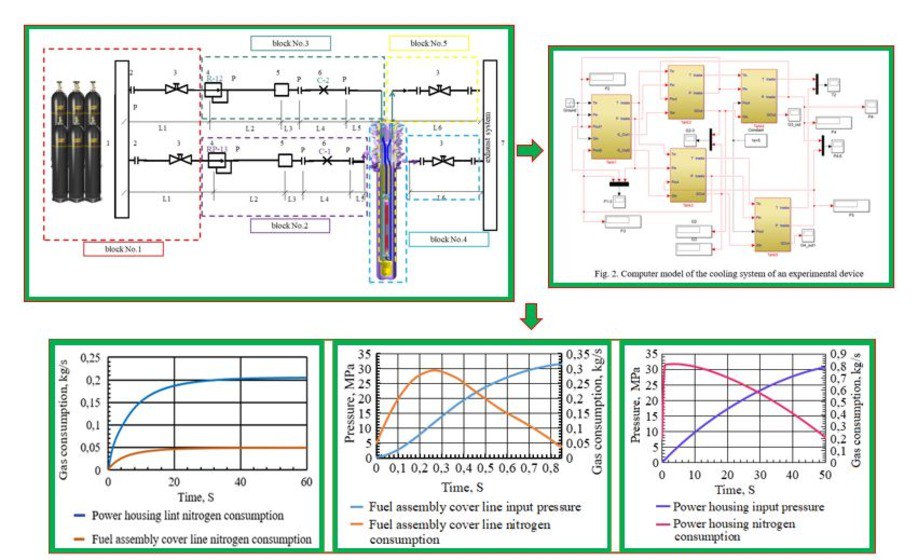

The article is devoted to the study of a nitrogen supply system for cooling an experimental device designed for testing in a pulsed reactor with a graphite moderator. To analyze emergency situations caused by disruption of the nitrogen supply system in the cooling paths of the fuel assembly cover and the experimental device power housing, a mathematical model has been developed to describe thermodynamic processes in a system of interconnected tanks that simulate individual sections of the experimental device hydrodynamic cooling system in a pulsed graphite reactor and implemented in the mathematical interactive package for engineering calculations in MATLAB/Simulink. To study the normal operation of the system and analyze possible emergencies, the cooling system of the experimental device was presented in the form of groups of interconnected sections of the hydrodynamic system-tanks, with specified volumes and hydraulic resistances of pipelines connecting these tanks. Verification of the model, calculations of the experimental device cooling system normal operation mode, calculations of emergency situations caused by a violation of the nitrogen supply system normal operation in the cooling paths of the fuel assembly cover were carried out, in particular, it was found that for the cooling system of the experimental device WF-2, the breakdown of the gearbox P-12 can cause depressurization of the fuel assembly cover and an increase in pressure in the power housing, the opening of the safety valve prevents exceeding the pressure limit in the housing, the device maintains integrity even in emergency situations, without being subjected to destruction of the power elements of the structure at a pressure of up to 8 MPa

References

- Shcherba, V. E., Pavlyuchenko, E. A., Nosov, E. Yu., Bulgakova, I. Yu. (2022). Approximation of the compression process to isothermal in a reciprocating compressor with a liquid piston. Applied Thermal Engineering, 207, 118151. doi: https://doi.org/10.1016/j.applthermaleng.2022.118151

- Batyrbekov, E., Vityuk, V., Vurim, A., Vityuk, G. (2023). Experimental opportunities and main results of the impulse graphite reactor use for research in safety area. Annals of Nuclear Energy, 182, 109582. doi: https://doi.org/10.1016/j.anucene.2022.109582

- Yang, L.-H., Liang, J.-D., Hsu, C.-Y., Yang, T.-H., Chen, S.-L. (2019). Enhanced efficiency of photovoltaic panels by integrating a spray cooling system with shallow geothermal energy heat exchanger. Renewable Energy, 134, 970–981. doi: https://doi.org/10.1016/j.renene.2018.11.089

- Hashem, G., Mahkamov, K., Belgasim, B., Elsharif, N., Makhkamova, I. (2021). Development and experimental investigation of a novel solar-powered cooling system. Energy Conversion and Management, 244, 114486. doi: https://doi.org/10.1016/j.enconman.2021.114486

- Wang, G., Yu, Y., Liu, H., Gong, C., Wen, S., Wang, X., Tu, Z. (2018). Progress on design and development of polymer electrolyte membrane fuel cell systems for vehicle applications: A review. Fuel Processing Technology, 179, 203–228. doi: https://doi.org/10.1016/j.fuproc.2018.06.013

- Zabriskie, A., Schunert, S., Schwen, D., Ortensi, J., Baker, B., Wang, Y. et al. (2018). A Coupled Multiscale Approach to TREAT LEU Feedback Modeling Using a Binary-Collision Monte-Carlo–Informed Heat Source. Nuclear Science and Engineering, 193 (4), 368–387. doi: https://doi.org/10.1080/00295639.2018.1528802

- Gupta, S., Sharma, V. K. (2020). Design and analysis of metal hydride reactor embedded with internal copper fins and external water cooling. International Journal of Energy Research, 45 (2), 1836–1856. doi: https://doi.org/10.1002/er.5859

- Akay, O. E., Das, M. (2021). Modeling the total heat transfer coefficient of a nuclear research reactor cooling system by different methods. Case Studies in Thermal Engineering, 25, 100914. doi: https://doi.org/10.1016/j.csite.2021.100914

- Vyawahare, V. A., Nataraj, P. S. V. (2013). Fractional-order modeling of neutron transport in a nuclear reactor. Applied Mathematical Modelling, 37 (23), 9747–9767. doi: https://doi.org/10.1016/j.apm.2013.05.023

- Vyawahare, V. A., Nataraj, P. S. V. (2013). Development and analysis of some versions of the fractional-order point reactor kinetics model for a nuclear reactor with slab geometry. Communications in Nonlinear Science and Numerical Simulation, 18 (7), 1840–1856. doi: https://doi.org/10.1016/j.cnsns.2012.11.012

- Krutov, V. I. (Ed.) (1981). Technical thermodynamics. Moscow: Higher School.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Zhaina Sakhanova, Zhenisgul Rakhmetullina, Roza Mukasheva, Raushan Mukhamedova, Indira Uvaliyeva, Galina Vityuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.