Оцінка експлуатаційних характеристик технології акумулювання тепла з використанням н-октакозану/полімеру низької щільності в якості зв'язуючого матеріалу

DOI:

https://doi.org/10.15587/1729-4061.2024.302627Ключові слова:

зв'язуючий матеріал, н-октакозан, робоча енергія, фазовий перехід, акумулювання енергіїАнотація

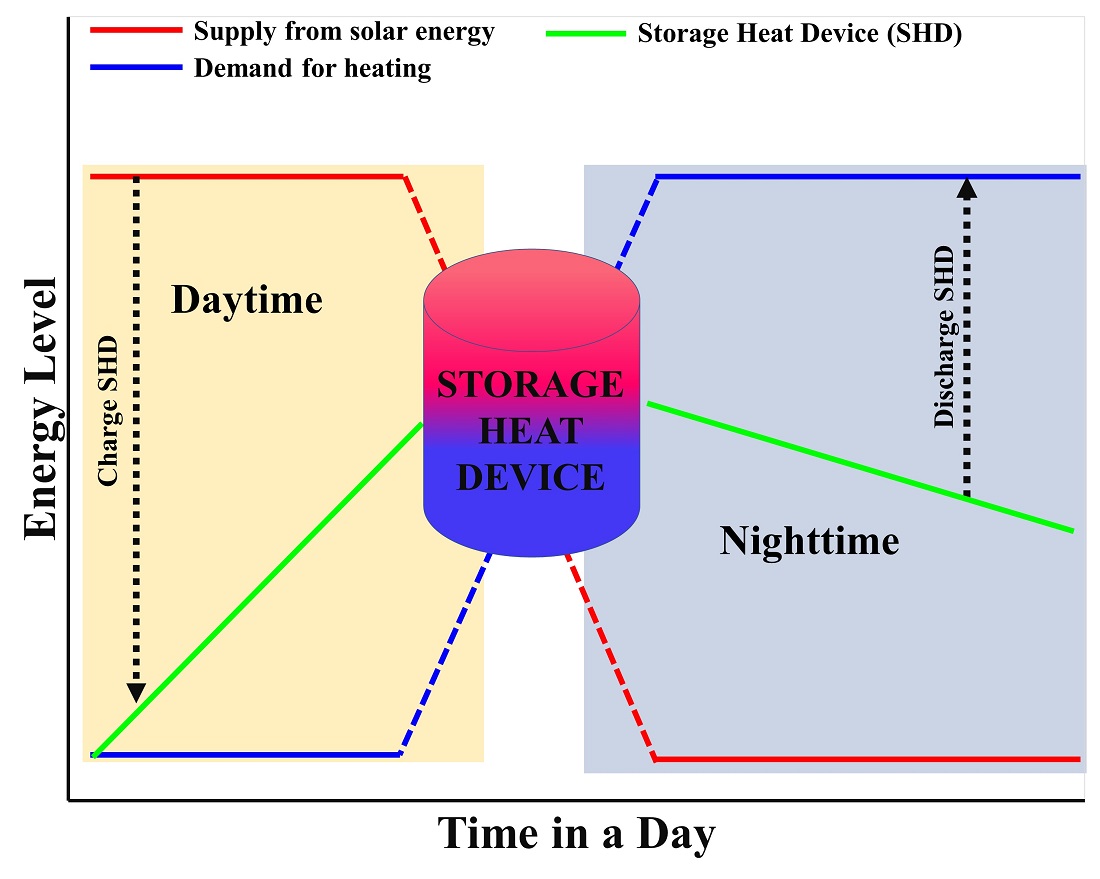

Технологія акумулювання тепла відіграє важливу роль у ряді застосувань, пов'язаних з використанням поновлюваних джерел теплової енергії (таких як сонячні водонагрівачі). Застосування воску (н-октакозану/OCT) в якості теплоакумулюючого середовища має великий позитивний вплив на систему. Однак експлуатаційні характеристики накопичувачів енергії на основі OCT несприятливі, що робить необхідним використання зв'язуючого матеріалу. У роботі в якості зв'язуючих матеріалів для OCT використовувалися полімери класу LD (LDPE) і лінійні LDPE. Суміш готується шляхом механічного гарячого перемішування та поділяється на дві категорії: SOCT1 (OCT/LD) та SOCT2 (OCT/LLD). Оцінка методом калориметрії показує збільшення температури переходу для SOCT на 2,1 °C та 5,5 °C. Це сприяє зміні значення енергії плавлення при переході з твердого стану в рідкий для обох матеріалів, що склало 132,05 Дж/г (SOCT1) та 113,4 Дж/г (SOCT2). Інша оцінка, пов'язана з хімічною та структурною фазою, показує, що SOCT має ідентичну структуру з OCT, що вказує на фізичне змішування SOCT. На експлуатаційному рівні SOCT більш оптимальний, ніж OCT за показником тривалості заряду та розряду для енергообміну. SOCT1 демонструє коротку лінію плато, що вказує на стійкий перехід між 65,4–67,9 °C, тоді як SOCT2 показує середню швидкість нагріву, яка є вищею, ніж для одинарного OCT. Крива тепловиділення для SOCT1 змінюється з нижчим значенням від 1,92 °C/хв до 0,77 °C/хв, тоді як SOCT2 має найменше значення зміни лише 0,17 °C/хв. Оцінка та аналіз, проведені у даній роботі показують, що SOCT дозволяє підвищити експлуатаційні характеристики OCT і може бути застосований для теплових систем

Посилання

- Mohammad Firman, L. O., Adji, R. B., Ismail, Rahman, R. A. (2023). Increasing the feasibility and storage property of cellulose-based biomass by forming shape-stabilized briquette with hydrophobic compound. Case Studies in Chemical and Environmental Engineering, 8, 100443. https://doi.org/10.1016/j.cscee.2023.100443

- Khademi, A., Darbandi, M., Schneider, G. E. (2020). Numerical Study to Optimize the Melting Process of Phase Change Material Coupled with Extra Fluid. AIAA Scitech 2020 Forum. https://doi.org/10.2514/6.2020-1932

- Suyitno, B. M., Rahman, R. A., Sukma, H., Rahmalina, D. (2022). The assessment of reflector material durability for concentrated solar power based on environment exposure and accelerated aging test. Eastern-European Journal of Enterprise Technologies, 6 (12 (120)), 22–29. https://doi.org/10.15587/1729-4061.2022.265678

- Favakeh, A., Khademi, A., Shafii, M. B. (2019). Experimental study of double solid phase change material in a cavity. 7th International Conference on Energy Research and Development, ICERD 2019, 24–31.

- Abtahi Mehrjardi, S. A., Khademi, A., Fazli, M. (2024). Optimization of a thermal energy storage system enhanced with fins using generative adversarial networks method. Thermal Science and Engineering Progress, 49, 102471. https://doi.org/10.1016/j.tsep.2024.102471

- Khademi, A., Mehrjardi, S. A. A., Said, Z., Chamkha, A. J. (2023). Heat Transfer Improvement in a Thermal Energy Storage System using Auxiliary Fluid Instead of Nano-PCM in an Inclined Enclosure: A Comparative Study. Journal of Applied and Computational Mechanics, 9 (2), 475–486. https://doi.org/10.22055/jacm.2022.41867.3829

- Zariatin, D. L., Suwandi, A. (2023). Advanced design of a small-scale mini gerotor pump in a high-temperature and high-viscosity fluid thermal system. Eastern-European Journal of Enterprise Technologies, 1 (8 (121)), 30–39. https://doi.org/10.15587/1729-4061.2023.272674

- Khademi, A., Darbandi, M., Behshad Shafii, M., Schneider, G. (2019). Numerical Simulation of Phase Change Materials to Predict the Energy Storage Process Accurately. AIAA Propulsion and Energy 2019 Forum. https://doi.org/10.2514/6.2019-4225

- Khademi, A., Mehrjardi, S. A. A., Tiari, S., Mazaheri, K., Shafii, M. B. (2022). Thermal Efficiency Improvement of Brayton Cycle in the Presence of Phase Change Material. Proceedings of the 9th International Conference on Fluid Flow, Heat and Mass Transfer (FFHMT’22). https://doi.org/10.11159/ffhmt22.135

- Favakeh, A., Khademi, A., Shafii, M. B. (2022). Experimental Investigation of the Melting Process of Immiscible Binary Phase Change Materials. Heat Transfer Engineering, 44 (2), 154–174. https://doi.org/10.1080/01457632.2022.2034085

- Rathore, P. K. S., Shukla, S. kumar. (2021). Improvement in thermal properties of PCM/Expanded vermiculite/expanded graphite shape stabilized composite PCM for building energy applications. Renewable Energy, 176, 295–304. https://doi.org/10.1016/j.renene.2021.05.068

- He, M., Xie, D., Yin, L., Gong, K., Zhou, K. (2023). Influences of reduction temperature on energy storage performance of paraffin wax/graphene aerogel composite phase change materials. Materials Today Communications, 34, 105288. https://doi.org/10.1016/j.mtcomm.2022.105288

- Li, S., Wang, H., Gao, X., Niu, Z., Song, J. (2023). Design of corn straw/paraffin wax shape-stabilized phase change materials with excellent thermal buffering performance. Journal of Energy Storage, 57, 106217. https://doi.org/10.1016/j.est.2022.106217

- Zarrinjooy Alvar, M., Abdeali, G., Bahramian, A. R. (2022). Influence of graphite nano powder on ethylene propylene diene monomer/paraffin wax phase change material composite: Shape stability and thermal applications. Journal of Energy Storage, 52, 105065. https://doi.org/10.1016/j.est.2022.105065

- Rahmalina, D., Zada, A. R., Soefihandini, H., Ismail, I., Suyitno, B. M. (2023). Analysis of the thermal characteristics of the paraffin wax/high-density polyethylene (HDPE) composite as a form-stable phase change material (FSPCM) for thermal energy storage. Eastern-European Journal of Enterprise Technologies, 1 (6 (121)), 6–13. https://doi.org/10.15587/1729-4061.2023.273437

- Sciacovelli, A., Navarro, M. E., Jin, Y., Qiao, G., Zheng, L., Leng, G. et al. (2018). High density polyethylene (HDPE) – Graphite composite manufactured by extrusion: A novel way to fabricate phase change materials for thermal energy storage. Particuology, 40, 131–140. https://doi.org/10.1016/j.partic.2017.11.011

- Abtahi Mehrjardi, S. A., Khademi, A., Said, Z., Ushak, S., Chamkha, A. J. (2023). Enhancing latent heat storage systems: The impact of PCM volumetric ratios on energy storage rates with auxiliary fluid assistance. Energy Nexus, 11, 100227. https://doi.org/10.1016/j.nexus.2023.100227

- Wang, H., Rao, Z., Li, L., Liao, S. (2023). A novel composite phase change material of high-density polyethylene/d-mannitol/expanded graphite for medium-temperature thermal energy storage: Characterization and thermal properties. Journal of Energy Storage, 60, 106603. https://doi.org/10.1016/j.est.2022.106603

- Harmen, Y., Chhiti, Y., Alaoui, F. E. M., Bentiss, F., Elkhouakhi, M., Deshayes, L. et al. (2020). Storage efficiency of paraffin-LDPE-MWCNT phase change material for industrial building applications. 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC). https://doi.org/10.1109/redec49234.2020.9163856

- Yu, Y., Qin, H., Ran, S., Song, J., Xia, W., Wang, S., Xiong, C. (2023). A Low-Density Polyethylene-Reinforced Ternary Phase-Change Composite with High Thermal Conductivity for Battery Thermal Management. Energies, 16 (9), 3838. https://doi.org/10.3390/en16093838

- Al-Gunaid, T., Sobolčiak, P., Chriaa, I., Karkri, M., Mrlik, M., Ilčíková, M. et al. (2023). Phase change materials designed from Tetra Pak waste and paraffin wax as unique thermal energy storage systems. Journal of Energy Storage, 64, 107173. https://doi.org/10.1016/j.est.2023.107173

- Zhao, J., Rui, Z., Hu, Z., Shangguan, Z., Yin, S., Peng, H. (2024). Flexible phase change materials based on hexagonal boron nitride (hBN) surface modification and styrene-butadiene-styrene (SBS)/low-density polyethylene (LDPE) crosslinking for battery thermal management applications. Chemical Engineering Journal, 485, 150110. https://doi.org/10.1016/j.cej.2024.150110

- Patil, J. R., Mahanwar, P. A., Sundaramoorthy, E., Mundhe, G. S. (2023). A review of the thermal storage of phase change material, morphology, synthesis methods, characterization, and applications of microencapsulated phase change material. Journal of Polymer Engineering, 43 (4), 354–375. https://doi.org/10.1515/polyeng-2022-0254

- Wang, Z., Zhang, X., Xu, Y., Chen, G., Lin, F., Ding, H. (2021). Preparation and thermal properties of shape-stabilized composite phase change materials based on paraffin wax and carbon foam. Polymer, 237, 124361. https://doi.org/10.1016/j.polymer.2021.124361

- Firman, L. O. M., Rahmalina, D., Ismail, Rahman, R. A. (2023). Hybrid energy-temperature method (HETM): A low-cost apparatus and reliable method for estimating the thermal capacity of solid–liquid phase change material for heat storage system. HardwareX, 16, e00496. https://doi.org/10.1016/j.ohx.2023.e00496

- Suyitno, B. M., Anggrainy, R., Plamonia, N., Rahman, R. A. (2023). Preliminary characterization and thermal evaluation of a direct contact cascaded immiscible inorganic salt/high-density polyethylene as moderate temperature heat storage material. Results in Materials, 19, 100443. https://doi.org/10.1016/j.rinma.2023.100443

- Janghel, D., Karagadde, S., Saha, S. K. (2023). Measurement of shrinkage void and identification of solid-liquid phases in phase change materials: Ultrasound-based approach and simulated predictions. Applied Thermal Engineering, 223, 120048. https://doi.org/10.1016/j.applthermaleng.2023.120048

- Wu, M. Q., Wu, S., Cai, Y. F., Wang, R. Z., Li, T. X. (2021). Form-stable phase change composites: Preparation, performance, and applications for thermal energy conversion, storage and management. Energy Storage Materials, 42, 380–417. https://doi.org/10.1016/j.ensm.2021.07.019

- Cui, W., Li, X., Li, X., Lu, L., Ma, T., Wang, Q. (2022). Combined effects of nanoparticles and ultrasonic field on thermal energy storage performance of phase change materials with metal foam. Applied Energy, 309, 118465. https://doi.org/10.1016/j.apenergy.2021.118465

- Bastida, H., De la Cruz-Loredo, I., Ugalde-Loo, C. E. (2023). Effective estimation of the state-of-charge of latent heat thermal energy storage for heating and cooling systems using non-linear state observers. Applied Energy, 331, 120448. https://doi.org/10.1016/j.apenergy.2022.120448

- Rahmalina, D., Adhitya, D. C., Rahman, R. A., Ismail, I. (2021). Improvement the performance of composite PCM paraffin-based incorporate with volcanic ash as heat storage for low-temperature application. EUREKA: Physics and Engineering, 1, 53–61. https://doi.org/10.21303/2461-4262.2022.002055

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Reza Abdu Rahman, Sulistyo, Mohamad Said Kartono Tony Suryo Utomo, Robertus Dhimas Dhewangga Putra

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.