Визначення можливості виготовлення шовковичного вина із застосуванням процесу осмотичної дегідратації

DOI:

https://doi.org/10.15587/1729-4061.2024.306443Ключові слова:

шовковиця чорна, шовковичне вино, нетрадиційна сировина, органолептичні показники, осмотична дегідратаціяАнотація

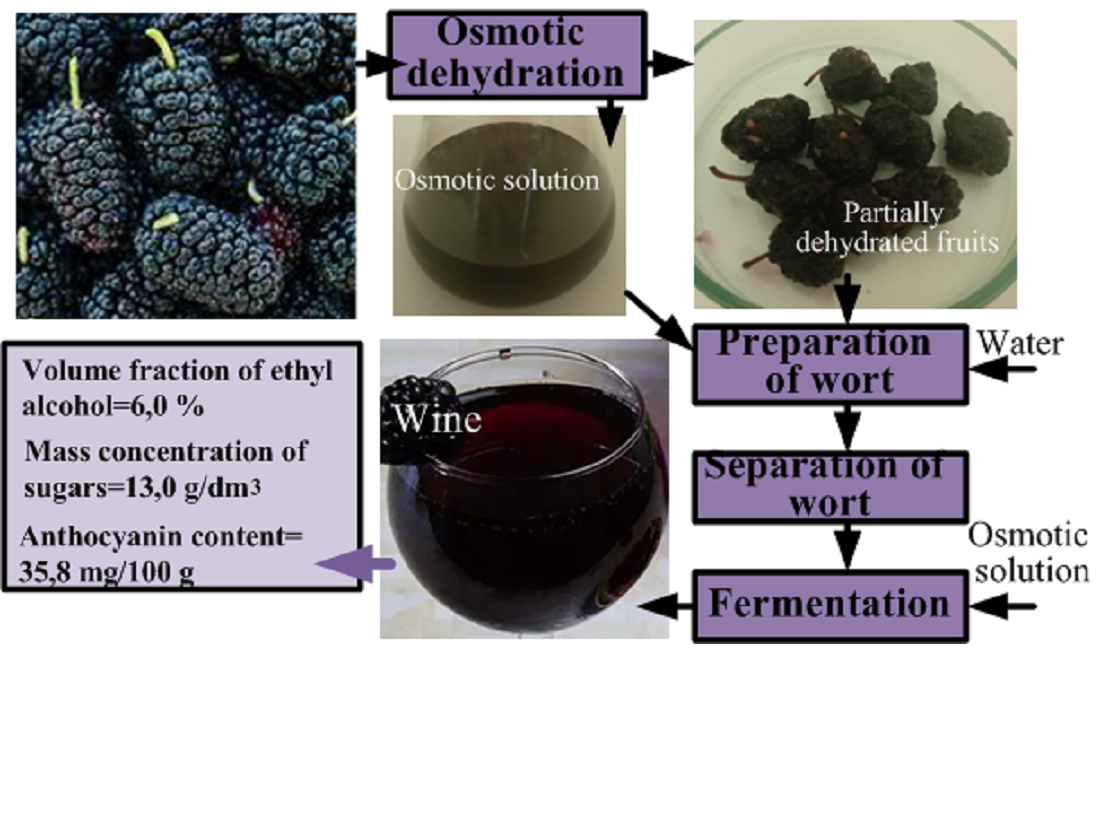

Це дослідження мало на меті визначити можливість застосування осмотичної дегідратації при виробництві вина з шовковиці. Плоди шовковиці (Mórus nígra L.) змішували із 70 % розчином сахарози і проводили осмотичну дегідратацію (τ=1 год, t=50±5 °C). На етапі активного бродіння осмотичний розчин, відокремлений від плодів, вносили у сусло (10 % до маси). Частково зневоднені плоди шовковиці 12 годин настоювали у воді при температурі 10–15 °С. Утворене сусло відокремлювали від плодів, змішували з осмотичним розчином та розчином, утвореним при пресуванні зневоднених плодів. Суміш ферментували при 20±2 °C протягом 20 днів в статичних умовах. По закінченню бродіння молоде вино витримували при температурі 3–5 °С протягом 1 місяця. Проводили друге переливання та аналізували показники його якості. Встановлено, що осмотичні розчини, утворені при осмотичній дегідратації плодів шовковиці чорної, містять 42,60 ± 0,25 мг/100 г антоціанів, що робить їх ефекативною основою та добавкою для надання вину бажаних сенсорних характеристик. Високий вміст антоціанів у вині (35,8±0,5 мг/100 г) забезпечує його стійкий червоно-рубіновий колір. Внаслідок гідролізу сахароза, яка була основним компонентом осмотичного розчину перед зневодненням шовковиці, перетворюється на глюкозу (27,74±0,05 г/100 г) та фруктозу (28,60±0,05 г/100 г). Це значно підвищує його біологічну цінність та надає вину гармонійного смаку, притаманного фруктовим винам. Вино виготовлене на основі продуктів переробки плодів шовковиці оцінено в 7,5 балів. Воно мало приємний смак та колір, але слаборозвинутий аромат. Шовковичне вино було класифіковано, як напівсухе, оскільки воно мало невисокий вміст алкоголю (6±0,5 %), низьку концентрацію цукрів (13,0±0,5 г/дм3) та високу концентрацію летких кислот (1,4±0,5 г/дм3)

Посилання

- Ding, B., Zhao, S., Zhang, W., Lin, Y., Xiong, L. (2024). The Effect of Co-Culture with Different Pichia kluyveri and Saccharomyces cerevisiae on Volatile Compound and Characteristic Fingerprints of Mulberry Wine. Foods, 13 (3), 422. https://doi.org/10.3390/foods13030422

- Skrovankova, S., Ercisli, S., Ozkan, G., Ilhan, G., Sagbas, H. I., Karatas, N. et al. (2022). Diversity of Phytochemical and Antioxidant Characteristics of Black Mulberry (Morus nigra L.) Fruits from Turkey. Antioxidants, 11 (7), 1339. https://doi.org/10.3390/antiox11071339

- Tao, Y., Wang, Y., Yang, J., Wang, Q., Jiang, N., Chu, D.-T. et al. (2017). Chemical composition and sensory profiles of mulberry wines as fermented with differentSaccharomyces cerevisiaestrains. International Journal of Food Properties, 1–16. https://doi.org/10.1080/10942912.2017.1361970

- On-Nom, N., Suttisansanee, U., Tongmai, J., Khemthong, C., Chamchan, R., Prangthip, P. et al. (2020). Consumption of Anthocyanin-Rich Mulberry Fruit Jelly with a High-Fat Meal Decreases Postprandial Serum Cardiometabolic Risk Factors in Dyslipidemia Subjects. Journal of Nutrition and Metabolism, 2020, 1–9. https://doi.org/10.1155/2020/1370951

- Maqsood, M., Anam Saeed, R., Sahar, A., Khan, M. I. (2022). Mulberry plant as a source of functional food with therapeutic and nutritional applications: A review. Journal of Food Biochemistry, 46 (11). https://doi.org/10.1111/jfbc.14263

- Jan, B., Parveen, R., Zahiruddin, S., Khan, M. U., Mohapatra, S., Ahmad, S. (2021). Nutritional constituents of mulberry and their potential applications in food and pharmaceuticals: A review. Saudi Journal of Biological Sciences, 28 (7), 3909–3921. https://doi.org/10.1016/j.sjbs.2021.03.056

- Cheng, K.-C., Wang, C.-J., Chang, Y.-C., Hung, T.-W., Lai, C.-J., Kuo, C.-W., Huang, H.-P. (2020). Mulberry fruits extracts induce apoptosis and autophagy of liver cancer cell and prevent hepatocarcinogenesis in vivo. Journal of Food and Drug Analysis, 28 (1), 84–93. https://doi.org/10.1016/j.jfda.2019.06.002

- Pretorius, I. S. (2019). Tasting the terroir of wine yeast innovation. FEMS Yeast Research, 20 (1). https://doi.org/10.1093/femsyr/foz084

- Feng, Y., Liu, M., Ouyang, Y., Zhao, X., Ju, Y., Fang, Y. (2015). Comparative study of aromatic compounds in fruit wines from raspberry, strawberry, and mulberry in central Shaanxi area. Food & Nutrition Research, 59 (1), 29290. https://doi.org/10.3402/fnr.v59.29290

- Wang, L., Sun, X., Li, F., Yu, D., Liu, X., Huang, W., Zhan, J. (2015). Dynamic changes in phenolic compounds, colour and antioxidant activity of mulberry wine during alcoholic fermentation. Journal of Functional Foods, 18, 254–265. https://doi.org/10.1016/j.jff.2015.07.013

- Luo, B., Yang, Y., Lin, Q. (2024). Optimizing yeast strain selection for mulberry wine fermentation: a performance-based approach. Quality Assurance and Safety of Crops & Foods, 16 (1), 60–68. https://doi.org/10.15586/qas.v16i1.1415

- Tinrat, S. (2024). Bioactive compounds of mulberry fruit and assessment of the effect of Saccharomyces cerevisiae strains on the quality of mulberry wine products. Food Research, 8 (2), 167–177. https://doi.org/10.26656/fr.2017.8(2).177

- Echeverrigaray, S., Scariot, F. J., Menegotto, M., Delamare, A. P. L. (2020). Anthocyanin adsorption by Saccharomyces cerevisiae during wine fermentation is associated to the loss of yeast cell wall/membrane integrity. International Journal of Food Microbiology, 314, 108383. https://doi.org/10.1016/j.ijfoodmicro.2019.108383

- Zhang, S., Xing, X., Chu, Q., Sun, S., Wang, P. (2022). Impact of co-culture of Lactobacillus plantarum and Oenococcus oeni at different ratios on malolactic fermentation, volatile and sensory characteristics of mulberry wine. LWT, 169, 113995. https://doi.org/10.1016/j.lwt.2022.113995

- Hu, J., Vinothkanna, A., Wu, M., Ekumah, J., Akpabli‐Tsigbe, N. D. K., Ma, Y. (2021). Tracking the dynamic changes of a flavor, phenolic profile, and antioxidant properties of Lactiplantibacillus plantarum‐ and Saccharomyces cerevisiae‐fermented mulberry wine. Food Science & Nutrition, 9 (11), 6294–6306. https://doi.org/10.1002/fsn3.2590

- Xiong, Q.-M., Liu, J., Liu, M., Shen, C.-H., Yu, X.-C., Wu, C.-D. et al. (2020). Fouling analysis and permeate quality evaluation of mulberry wine in microfiltration process. RSC Advances, 10 (2), 655–665. https://doi.org/10.1039/c9ra09034g

- Samilyk, M., Bal’-Prylipko, L., Korniienko, D., Paska, M., Ryzhkova, T., Yatsenko, I. et al. (2023). Determination of quality indicators of sugar fortified with a by-product of elderberry processing. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 65–72. https://doi.org/10.15587/1729-4061.2023.284885

- Liu, S., Vega, A. R., Dizy, M. (2023). Assessing ultrapremium red wine quality using PLS-SEM. LWT, 177, 114560. https://doi.org/10.1016/j.lwt.2023.114560

- Fan, S., Liu, C., Li, Y., Zhang, Y. (2023). Visual Representation of Red Wine Color: Methodology, Comparison and Applications. Foods, 12 (5), 924. https://doi.org/10.3390/foods12050924

- Negro, C., Aprile, A., De Bellis, L., Miceli, A. (2019). Nutraceutical Properties of Mulberries Grown in Southern Italy (Apulia). Antioxidants, 8 (7), 223. https://doi.org/10.3390/antiox8070223

- He, F., Liang, N.-N., Mu, L., Pan, Q.-H., Wang, J., Reeves, M. J., Duan, C.-Q. (2012). Anthocyanins and Their Variation in Red Wines I. Monomeric Anthocyanins and Their Color Expression. Molecules, 17 (2), 1571–1601. https://doi.org/10.3390/molecules17021571

- Ursu, M. S., Aprodu, I., Milea, Ștefania A., Enachi, E., Râpeanu, G. et al. (2020). Thermal Degradation Kinetics of Anthocyanins Extracted from Purple Maize Flour Extract and the Effect of Heating on Selected Biological Functionality. Foods, 9 (11), 1593. https://doi.org/10.3390/foods9111593

- Fan, S., Zhang, Y., Li, Y. (2023). A New Approach for Quantitative Classification of Red Wine Color from the Perspective of Micro and Macro Levels. Fermentation, 9 (6), 519. https://doi.org/10.3390/fermentation9060519

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Maryna Samilyk, Mykola Nosyk, Taisia Ryzhkova, Nataliia Bolhova, Svetlana Tkachuk, Anna Sakhnenko, Alla Petrenko, Dmytro Hrinchenko, Ihor Hnoievyi

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.