The impact of grain sorghum on the carbohydrate composition of wort for non-alcoholic beer

DOI:

https://doi.org/10.15587/1729-4061.2022.265190Keywords:

brewing industry, non-alcoholic beer, malt mashing, grain sorghum, carbohydrate composition, extractivityAbstract

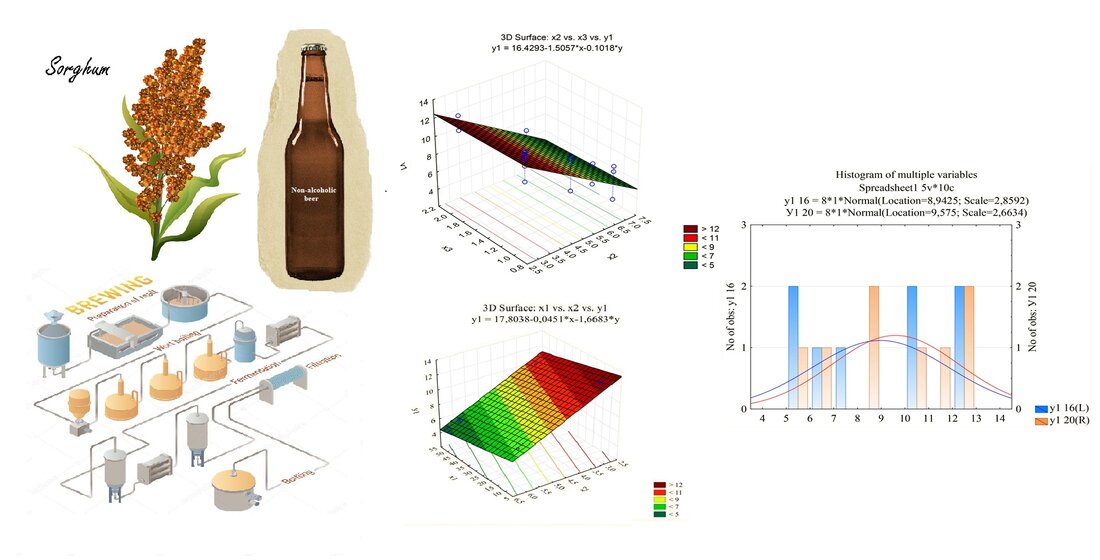

The production of non-alcoholic beer requires brewing wort with a low degree of digestion. That is possible with the use of non-traditional raw materials in production. The research object presented below is grain sorghum varieties Kazakhstan-16 and Kazakhstan-20. Nowadays, the production of non-alcoholic beer with technological methods is not studied enough. Therefore, plants with small capacities cannot produce it. This study justifies the use of grain sorghum to produce low-digestion wort. In addition, we justify that Kazakhstan-16 had the best indicators for producing non-alcoholic beer. The following ratio of malt for wort preparation to sorghum 60:40 and hydro module 1:6 are proposed. The prepared wort had an extractivity of 6.62 % and digestible carbohydrates of 25.89 % of the total. The ratio of digestible sugars to non-fermentable substances in the wort was 1:1.79, so 79 % constituted mainly non-fermentable sugars.

Mathematical experiment planning has been used to study the effect of malt and sorghum filling ratio and hydro module on the brewing wort's extractive matter yield.

Based on the results of this study, the brewing wort has a low digestion rate. However, the carbohydrate composition of the wort is due to the presence of mono- and disaccharides. This wort will produce a beer with an ethanol content of up to 0.5 % of alcohol and the organoleptic characteristics set.

High extractivity in the raw materials and their high gelling temperature account for these results. These factors made it possible to select a jumping mashing regime, which resulted in deep hydrolysis of the sugars into dextrins.

This study will allow using non-traditional grain raw materials and producing non-alcoholic beer in breweries of any capacity. These methods are cost-effective and do not require expensive equipment

Supporting Agency

- We would like to thank “IP Efes Kazakhstan” JSC for sponsoring the purchase of a NANO BREWERY TYPE 50 L4 mini brewery and establishing a fermentation products training and research center based on the Almaty Technological University. This contribution enables scientific experiments in craft brewing.

References

- Puligundla, P., Smogrovicova, D., Mok, C., Obulam, V. S. R. (2020). Recent developments in high gravity beer-brewing. Innovative Food Science & Emerging Technologies, 64, 102399. doi: https://doi.org/10.1016/j.ifset.2020.102399

- Volovelskaya, I. V., Kuleshov, B. (2017). Modern trends in the development of the beer market in Ukraine. Visnyk ekonomiky transportu i promyslovosti, 5. Available at: https://cyberleninka.ru/article/n/sovremennye-tendentsii-razvitiya-pivnogo-rynka-v-ukraine

- Oganesyants, L. A., Sarkisov, G. I., Magomedov, M. D., Alekseycheva, E. Yu. (2012). Effektivnost' razvitiya predpriyatiy pivovarennoy otrasli. Pivo i napitki, 3, 4–8. Available at: https://cyberleninka.ru/article/n/effektivnost-razvitiya-predpriyatiy-pivovarennoy-otrasli

- Zhaksygulova, A., Baigaziyeva, G. I., Kekibayeva, A. K. (2022). Research of the quality of dense wort for production of special purpose beer. The Journal of Almaty Technological University, 1, 35–41. doi: https://doi.org/10.48184/2304-568x-2022-1-35-41

- Shintassova, S. M., Baigazieva, G. I., Kiseleva, T. F., Uvakasova, G. T., Askarbekov, E. B. (2019). Improving the quality of brewing malt with the use of ion-ozone explosive cavitation. EurAsian Journal of BioSciences, 13, 277–286. Available at: https://distance.atu.kz/files/1moderator/FPP_ATU/Document/%D0%A1%D1%82%D0%B0%D1%82%D1%8C%D0%B8/ru/%D0%A8%D0%B8%D0%BD%D1%82%D0%B0%D1%81%D0%BE%D0%B2%D0%B0%20%D0%A1.%D0%9C..pdf

- Durga Prasad, C. G., Vidyalakshmi, R., Baskaran, N., Tito Anand, M. (2022). Influence of Pichia myanmarensis in fermentation to produce quinoa based non-alcoholic beer with enhanced antioxidant activity. Journal of Cereal Science, 103, 103390. doi: https://doi.org/10.1016/j.jcs.2021.103390

- Gernat, D. C., Brouwer, E. R., Faber-Zirkzee, R. C., Ottens, M. (2020). Flavour-improved alcohol-free beer – Quality traits, ageing and sensory perception. Food and Bioproducts Processing, 123, 450–458. doi: https://doi.org/10.1016/j.fbp.2020.07.014

- Adamenko, K., Kawa-Rygielska, J., Kucharska, A. Z. (2020). Characteristics of Cornelian cherry sour non-alcoholic beers brewed with the special yeast Saccharomycodes ludwigii. Food Chemistry, 312, 125968. doi: https://doi.org/10.1016/j.foodchem.2019.125968

- Ogannisyan, V. G. (2007). Bezalkogol'noe pivo i tekhnologii ego polucheniya. Pivo i napitki, 6, 19–23. Available at: https://cyberleninka.ru/article/n/bezalkogolnoe-pivo-i-tehnologii-ego-polucheniya

- Oganesian, V. G, Petrova, N. A., Tamazian, G. A. (2010). Membrane methods of beer dealcoholizing. Nauchniy zhurnal NIU ITMO. Seriya «Protsessy i apparaty pischevykh proizvodstv», 2. Available at: https://cyberleninka.ru/article/n/membrannye-metody-dealkogolizatsii-piva

- Zdaniewicz, M., Pater, A., Knapik, A., Duliński, R. (2021). The effect of different oat (Avena sativa L) malt contents in a top-fermented beer recipe on the brewing process performance and product quality. Journal of Cereal Science, 101, 103301. doi: https://doi.org/10.1016/j.jcs.2021.103301

- Zdaniewicz, M., Pater, A., Hrabia, O., Duliński, R., Cioch-Skoneczny, M. (2020). Tritordeum malt: An innovative raw material for beer production. Journal of Cereal Science, 96, 103095. doi: https://doi.org/10.1016/j.jcs.2020.103095

- Burak, L. Ch., Sapach, A. N. (2021). The use of starch-containing raw materials in the production of beer and its influence on the quality of the finished product. Review of foreign literature. Mezhdunarodniy zhurnal prikladnykh nauk i tekhnologiy «Integral», 3. Available at: https://cyberleninka.ru/article/n/ispolzovanie-krahmalosoderzhaschego-syrya-v-proizvodstve-piva-i-ego-vliyanie-na-kachestvo-gotovogo-produkta-obzor-zarubezhnoy

- Ermolaeva, G. A. (2012). Pivo i pivnye napitki: tekhnologii i syr'e. Pivo i napitki, 3, 18–22. Available at: https://cyberleninka.ru/article/n/pivo-i-pivnye-napitki-tehnologii-i-syrie

- Bayazitova, M., Kekibaeva, A., Baigaziyeva, G., Askarbekov, E., Zhamalova, D. (2021). Analysis of the accumulation of amylolytic enzymes in triticale grain during malting process. Eastern-European Journal of Enterprise Technologies, 1 (11 (109), 42–50. doi: https://doi.org/10.15587/1729-4061.2021.224322

- Kozhukhova, A. V., Tsugkiev, B. G., Gevorkyants, R. A., Kiselev, I. V., Ermolaeva, G. A. (2007). Ispol'zovanie ovsa v pivovarenii. Pivo i napitki, 2, 16. Available at: https://cyberleninka.ru/article/n/ispolzovanie-ovsa-v-pivovarenii

- Kobelev, K. V., Boikov, A. V., Gribkova, I. N., Selina, I. V., Sozinova, M. S. (2014). Triticale malt production for beverages. Pivo i napitki, 5, 36–39. Available at: https://cyberleninka.ru/article/n/proizvodstvo-soloda-iz-tritikale-dlya-napitkov-brozheniya

- Abramova, A. V., Meledina, T. V., Fedorova, R. A. (2016). Perspektivy i Problemy ispol'zovaniya sorgo dlya sozdaniya bezglyutenovoy produktsii. Izvestiya SPbGAU, 42. Available at: https://cyberleninka.ru/article/n/perspektivy-i-problemy-ispolzovaniya-sorgo-dlya-sozdaniya-bezglyutenovoy-produktsii

- Kuntse, V. (2009). Tekhnologiya soloda i piva. Sankt-Peterburg: Professiya, 912.

- Borisenko, T. N., Kardasheva, M. V. (2014). Tekhnologiya otrasli. Tekhnologiya piva. Kemerovo: Kemerovskiy tekhnologicheskiy institut pischevoy promyshlennosti, 122.

- Balakay, S. G. (2012). Sorghum - the crop of ample possibilities. Nauchniy zhurnal Rossiyskogo NII problem melioratsii, 1 (05). Available at: https://cyberleninka.ru/article/n/sorgo-kultura-bolshih-vozmozhnostey

- Askarbekov, E., Baigazieva, G., Zhienbaeva, S., Batyrbaeva, N., Iztaev, A., Uvakasova, G., Serikbaeva, A. (2018). Comparison of different industrial strains of dry yeast for industrial fermentation of sweet sorghum syrup. Bioscience Research, 15, 1048–1062. Available at: http://www.scopus.com/inward/record.url?eid=2-s2.0-85050207421&partnerID=MN8TOARS

- Makushin, A. N. (2019). Primenenie zerna sorgo razlichnykh sortov pri proizvodstve neokhmelennogo susla svetlykh sortov piva. Vklad molodykh uchenykh v agrarnuyu nauku. Kinel', 549–551. doi: https://doi.org/10.24411/2588-0209-2020-10187

- Gómez Pamies, L. C., Lataza Rovaletti, M. M., Martinez Amezaga, N. M. J., Benítez, E. I. (2021). The impact of pirodextrin addition to improve physicochemical parameters of sorghum beer. LWT, 149, 112040. doi: https://doi.org/10.1016/j.lwt.2021.112040

- Coulibaly, W., Alfred, K. K., Bi, Y. C. T., N'sa, K. M. C. et. al. (2020). Influence of yeasts on bioactive compounds content of traditional sorghum beer (tchapalo) produced in Côte d'Ivoire. Current Research in Food Science, 3, 195–200. doi: https://doi.org/10.1016/j.crfs.2020.06.001

- Pomozova, V. A., Potapov, A. N., Potitina, U. S., Prosin, M. V. (2012). Sovershenstvovanie protsessa zatiraniya pri proizvodstve piva. Vestnik KrasGAU, 12, 45–51. Available at: https://cyberleninka.ru/article/n/sovershenstvovanie-protsessa-zatiraniya-pri-proizvodstve-piva

- Petrova, N. A., Ogannisyan, V. G., Ivanchenko, O. B. (2011). Sposob prigotovleniya bezalkogol'nogo grechishnogo piva. Pivo i napitki, 5, 12–14.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Azhar Kerimbayeva, Auyelbek Iztayev, Gulgaisha Baigaziyeva, Anara Kekibaeva, Ludek Hrivna, Meruyert Bayazitova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.