Determining patterns of the deformed state of the transport concrete pipe reinforced with a metal clamp under the action of static load

DOI:

https://doi.org/10.15587/1729-4061.2022.265813Keywords:

concrete pipe, metal clamp, deformation diagram, three-layer structure, static loadAbstract

The object of this study is a concrete pipe and a pipe whose integrity was restored using a metal clamp while filling the layer between the existing pipe and the metal clamp with self-expanding concrete mortar.

It has been established that the most common types of defects and damage to pipes on the roads are transverse and longitudinal cracks, as well as concrete chipping and spalling.

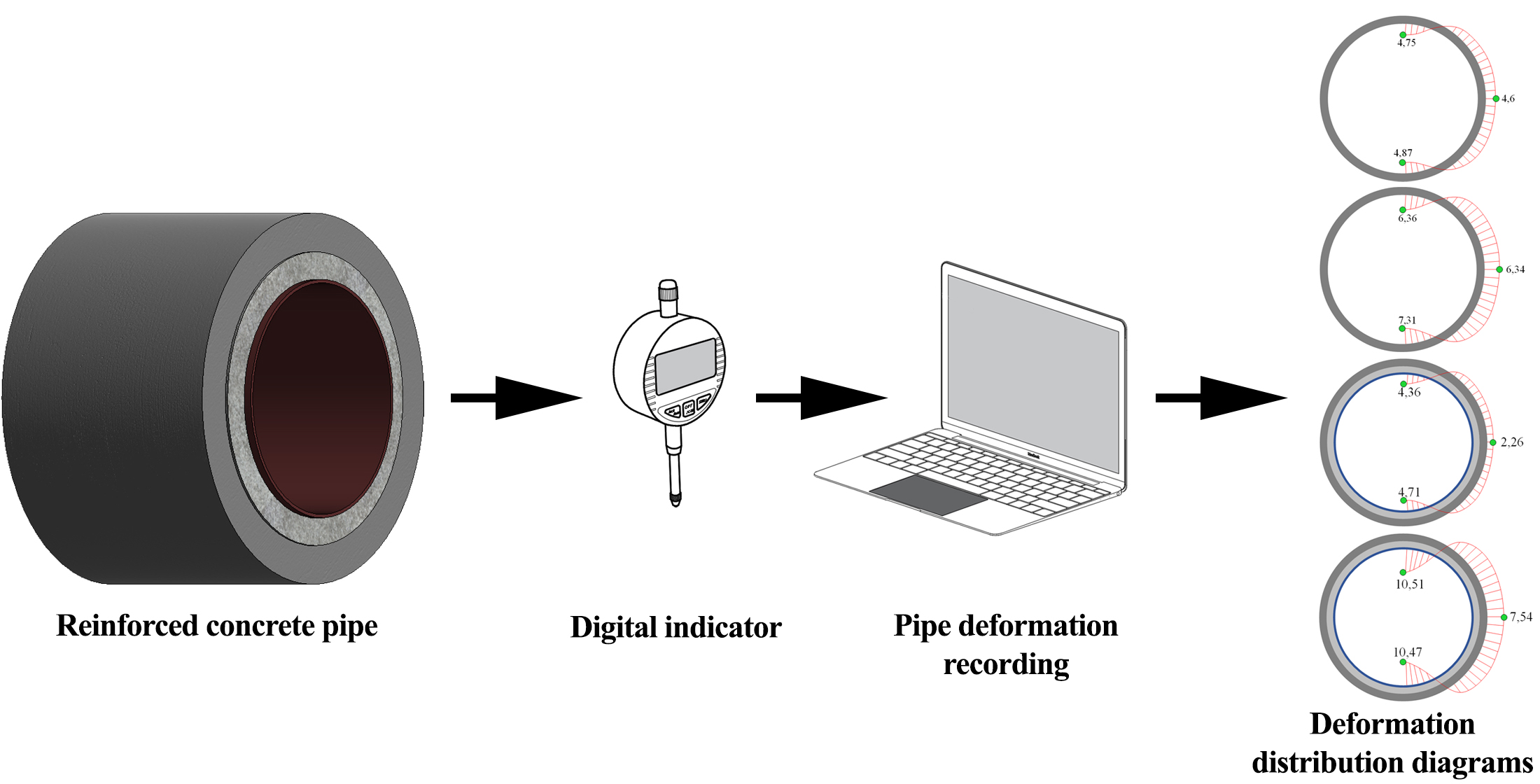

A procedure has been devised to test experimentally a new concrete pipe without reinforcement and a concrete pipe reinforced with a metal clamp under static load.

Experimental tests of the concrete pipe without reinforcement and with reinforcement with a metal clamp were carried out in the laboratory. Digital indicators, an analog-to-digital converter, and a personal computer were used to measure pipe deformations.

It was found that the maximum value of vertical deformations of a new concrete pipe before cracking was 4.75 mm, and that reinforced by a metal clamp – 4.36 mm. At the same time, the maximum deformation at which the destruction of the new pipe occurred was 6.36 mm, and that of the reinforced pipe with a metal clamp – 10.51 mm.

It was established that the reinforcement of the destroyed pipe with a metal clamp in the initial period of loading leads to detachment of the clamp from the concrete of the pipe. Further, when the clamps are included in the work, there is a stable operation of the concrete pipe and the amount of growth of pipe deformations increases smoothly.

The results of measuring vertical deformations at the top of the pipe without reinforcement and with it showed different deformation values. It was established that the complete destruction of the pipe with a reinforced metal clamp takes place during deformations 61 % higher than the deformation at which the non-reinforced new concrete pipe is destroyed.

It was found that one of the methods of restoring the bearing capacity of damaged and defective pipes in the road industry is the use of metal clamps

References

- Pshinko, A. N., Rudenko, N. N. (2000). Problemy remonta inzhenernykh transportnykh sooruzhenii. Zalіznichnii transport Ukraini, 3, 12–14. Available at: https://scholar.google.com/citations?view_op=view_citation&hl=ca&user=oSlrDJMAAAAJ&citation_for_view=oSlrDJMAAAAJ:CaZNVDsoPx4C

- Pshinko, A. N. (2000). Podvodnoe betonirovanie i remont iskusstvennykh sooruzhenii. Dnepropetrovsk: Porogi, 411.

- Pshinko, O. M. Soldatov, K. I., Krasniuk, A. V., Pshinko, P. O. (2008). The Systematization of Defects in Concrete Structures and Ways of Their Elimination. Visnyk Dnipropetrovskoho natsionalnoho universytetu zaliznychnoho transportu imeni akademika V. Lazariana, 22, 106–113. Available at: http://eadnurt.diit.edu.ua/handle/123456789/2859

- Kovalchuk, V., Hnativ, Y., Luchko, J., Sysyn, M. (2020). Study of the temperature field and the thermos-elastic state of the multilayer soil-steel structure. Roads and Bridges, 19 (1), 65–78. doi: https://doi.org/10.7409/rabdim.020.004

- Mistewicz, M. (2019). Risk assessment of the use of corrugated metal sheets for construction of road soil-shell structures. Roads and Bridges-Drogi i Mosty, 18 (2), 89–107. doi: https://doi.org/10.7409/rabdim.019.006

- Kovalchuk, V., Markul, R., Pentsak, A., Parneta, B., Gayda, O., Braichenko, S. (2017). Study of the stress-strain state in defective railway reinforced-concrete pipes restored with corrugated metal structures. Eastern-European Journal of Enterprise Technologies, 5 (1 (89)), 37–44. doi: https://doi.org/10.15587/1729-4061.2017.109611

- Kovalchuk, V., Luchko, J., Bondarenko, I., Markul, R., Parneta, B. (2016). Research and analysis of the stressed-strained state of metal corrugated structures of railroad tracks. Eastern-European Journal of Enterprise Technologies, 6 (7 (84)), 4–9. doi: https://doi.org/10.15587/1729-4061.2016.84236

- Kovalchuk, V., Markul, R., Bal, O., Мilyanych, A., Pentsak, A., Parneta, B., Gajda, A. (2017). The study of strength of corrugated metal structures of railroad tracks. Eastern-European Journal of Enterprise Technologies, 2 (7 (86)), 18–25. doi: https://doi.org/10.15587/1729-4061.2017.96549

- Kovalchuk, V., Kovalchuk, Y., Sysyn, M., Stankevych, V., Petrenko, O. (2018). Estimation of carrying capacity of metallic corrugated structures of the type Multiplate MP 150 during interaction with backfill soil. Eastern-European Journal of Enterprise Technologies, 1 (1 (91)), 18–26. doi: https://doi.org/10.15587/1729-4061.2018.123002

- Liu, Y., Hoult, N. A., Moore, I. D. (2020). Structural Performance of In-Service Corrugated Steel Culvert under Vehicle Loading. Journal of Bridge Engineering, 25 (3). doi: https://doi.org/10.1061/(asce)be.1943-5592.0001524

- Machelski, C. (2016). Steel plate curvatures of soil-steel structure during construction and exploatition. Roads and Bridges, 15 (3), 207–220. doi: https://doi.org/10.7409/rabdim.016.013

- Bęben, D. (2013). Evaluation of backfill corrosivity around steel road culverts. Roads and Bridges, 12 (3), 255–268. doi: https://doi.org/10.7409/rabdim.013.018

- Gera, B., Kovalchuk, V. (2019). A study of the effects of climatic temperature changes on the corrugated structure. Eastern-European Journal of Enterprise Technologies, 3 (7 (99)), 26–35. doi: https://doi.org/10.15587/1729-4061.2019.168260

- Kovalchuk, V., Sysyn, M., Hnativ, Y., Onyshchenko, A., Koval, M., Tiutkin, O., Parneta, M. (2021). Restoration of the Bearing Capacity of Damaged Transport Constructions Made of Corrugated Metal Structures. The Baltic Journal of Road and Bridge Engineering, 16 (2), 90–109. doi: https://doi.org/10.7250/bjrbe.2021-16.529

- Machelski, C., Janusz, L., Czerepak, A. (2016). Estimation of Stress in the Crown of Soil-Steel Structures Based on Deformations. Journal of Traffic and Transportation Engineering, 4 (4), 186–193. doi: https://doi.org/10.17265/2328-2142/2016.04.002

- Machelski, C., Mumot, M. (2016). Corrugated Shell Displacements During the Passage of a Vehicle Along a Soil-Steel Structure. Studia Geotechnica et Mechanica, 38 (4), 25–32. doi: https://doi.org/10.1515/sgem-2016-0028

- Esmaeili, M., Zakeri, J. A., Abdulrazagh, P. H. (2013). Minimum depth of soil cover above long-span soil-steel railway bridges. International Journal of Advanced Structural Engineering, 5 (1), 7. doi: https://doi.org/10.1186/2008-6695-5-7

- Sysyn, M., Kovalchuk, V., Gerber, U., Nabochenko, O., Pentsak, A. (2020). Experimental study of railway ballast consolidation inhomogeneity under vibration loading. Pollack Periodica, 15 (1), 27–36. doi: https://doi.org/10.1556/606.2020.15.1.3

- Kovalchuk, V., Koval, M., Onyshchenko, A., Kravets, I., Bal, O., Markul, R. et. al. (2022). Determining the strained state of prefabricated metal corrugated structures of a tunnel overpass exposed to the dynamic loading from railroad rolling stock. Eastern-European Journal of Enterprise Technologies, 3 (7 (117)), 50–58. doi: https://doi.org/10.15587/1729-4061.2022.259439

- Kovalchuk, V., Sobolevska, Y., Onyshchenko, A., Bal, O., Kravets, I., Pentsak, A. et. al. (2022). Investigating the influence of the diameter of a fiberglass pipe on the deformed state of railroad transportation structure “embankment-pipe.” Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 35–43. doi: https://doi.org/10.15587/1729-4061.2022.254573

- AASHTO M 252, 2020 Edition, 2020 – Standard Specification for Corrugated Polyethylene Drainage Pipe. Available at: https://standards.globalspec.com/std/14289640/AASHTO%20M%20252

- Jafar, N. H., Ulloa, H. O. (2020). Literature Search on Use of Flexible Pipes in Highway Engineering for DOTD’s Needs. FHWA/LA.17/638. Dept. of Civil and Environmental Engineering Louisiana State University, 63.

- Kang, J., Jung, Y., Ahn, Y. (2013). Cover requirements of thermoplastic pipes used under highways. Composites Part B: Engineering, 55, 184–192. doi: https://doi.org/10.1016/j.compositesb.2013.06.025

- Babych, Ye. M., Karavan, V. V., Babych, V. Ye. (2018). Diahnostyka, pasportyzatsiia ta vidnovlennia budivel i inzhenernykh sporud. Rivne: Volynski oberehy, 129. Available at: http://ep3.nuwm.edu.ua/10637/

- Valovyi, O. I., Yeromenko, O. Yu. (2008). Otsinky mitsnosti zalizobetonnykh balok, pidsylenykh v stysnutii zoni efektyvnymy materialamy. Zbirnyk naukovykh prats Dorohy i mosty, 9, 22–28. Available at: http://dorogimosti.org.ua/files/upload/Zu_6.pdf

- Sokolska, M. K., Kolosova, A. S., Vitkalova, I. A., Torlova, A. S., Pikalov, Ye. S. (2017). Cpoluchni dlia otrymannia suchasnykh polimernykh kompozytsiinykh materialiv. Fundamentalni doslidzhennia, 10-2, 290–295.

- Bedi, R., Chandra, R., Singh, S. P. (2013). Mechanical Properties of Polymer Concrete. Journal of Composites, 2013, 1–12. doi: https://doi.org/10.1155/2013/948745

- Suh, J. D., Lee, D. G. (2008). Design and manufacture of hybrid polymer concrete bed for high-speed CNC milling machine. International Journal of Mechanics and Materials in Design, 4 (2), 113–121. doi: https://doi.org/10.1007/s10999-007-9033-3

- Mgherony, A. W., Mikó, B., Drégelyi-Kiss, Á. (2020). Design of experiment in investigation regarding milling machinery. Cutting & Tools in Technological System, 92, 68–84. doi: https://doi.org/10.20998/2078-7405.2020.92.09

- Hromova, O. V. (2006). Teoretychne doslidzhennia umov strukturnoi sumisnosti materialiv staroho i novoho betoniv pid chas remontu transportnykh sporud. Visnyk Dnipropetrovskoho natsionalnoho universytetu zaliznychnoho transportu imeni akademika V. Lazariana, 12, 165–169. Available at: http://nbuv.gov.ua/UJRN/vdnuzt_2006_12_36

- Hromova, O. V. (2007). Porivnialnyi analiz trysharovykh zrazkiv dlia riznykh fizyko-mekhanichnykh vlastyvostei. Visnyk Dnipropetrovskoho natsionalnoho universytetu zaliznychnoho transportu imeni akademika V. Lazariana, 14, 177–180. Available at: http://nbuv.gov.ua/UJRN/vdnuzt_2007_14_41

- Popov, V. O., Voiсehivsky, O. V. (2022). Method of reinforcement of reinforced concrete bridge supports by arrangement of bitrapezoidal casings. Modern Technology, Materials and Design in Construction, 32 (1), 5–13. doi: https://doi.org/10.31649/2311-1429-2022-1-5-13

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Vitalii Kovalchuk, Roman Rybak, Bogdan Parneta, Artur Onyshchenko, Roksolyana Kvasnytsya

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.