Improvement of cupcake technology with the addition of dried beet pomace

DOI:

https://doi.org/10.15587/1729-4061.2022.266337Keywords:

cupcake, plant-based supplement, dried beet pomace, effective viscosity, physiologically functional ingredientsAbstract

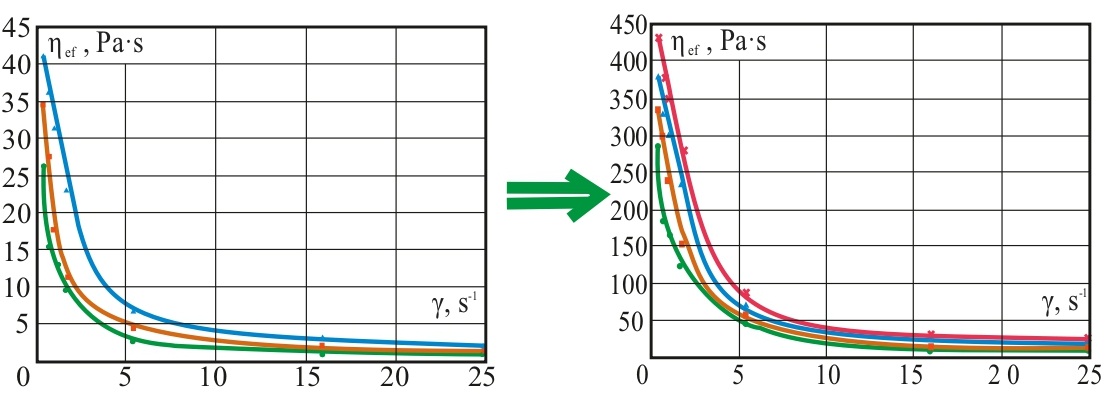

The object is de-sugared beet pomace, which contains a large amount of dietary fiber in its composition, as well as the technology of cupcakes with its addition. The task of enriching cupcakes with useful substances is tackled. A production technique of dried powdered beet pomace has been substantiated, which is characterized by low-temperature concentration modes in the rotary evaporator and post-drying in the roller IR dryer, which could contribute to the preservation of physiologically functional ingredients. The rheological characteristics of concentrated beet pomace in the rotary evaporator in the temperature range of 65–75 °C were determined. The established indicators revealed a tendency to reduce the effective viscosity depending on the temperature in the range of 42 to 27 Pa·s. For the speed of the rotary evaporator agitator of 200–300 min–1, the maximum level of effective viscosity of beet pomace of 3–5 Pa·s was established.

Studies of the rheological characteristics of the dough with the introduction of dried beet pomace have made it possible to establish an increase in its elastic-viscous properties with an increase in the amount of additive. The highest indicator of effective viscosity ηef (Pa∙s) of the studied dough samples for cupcakes with the addition of an additive of 10 % is 347; 15 % – 384; 20 % – 442; and control – 287, respectively. The compression of the crumb of finished cupcakes was also determined, which increases by 10.2–22.4 % with an increase in the amount of beet pomace powder. The organoleptic and physical-chemical indicators of the quality of cupcakes revealed the optimal amount of application of dried beet pomace – 15 %. The selected sample contains physiologically functional ingredients, namely dietary fiber, low molecular weight phenolic compounds, minerals. The technology can be introduced into the confectionery industry

References

- Bucher, T., van der Horst, K., Siegrist, M. (2013). Fruit for dessert. How people compose healthier meals. Appetite, 60, 74–80. https://doi.org/10.1016/j.appet.2012.10.003

- Pap, N., Fidelis, M., Azevedo, L., do Carmo, M. A. V., Wang, D., Mocan, A., Pereira, E. P. R. et al. (2021). Berry polyphenols and human health: evidence of antioxidant, anti-inflammatory, microbiota modulation, and cell-protecting effects. Current Opinion in Food Science, 42, 167–186. https://doi.org/10.1016/j.cofs.2021.06.003

- Galanakis, C. M., Rizou, M., Aldawoud, T. M. S., Ucak, I., Rowan, N. J. (2021). Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends in Food Science & Technology, 110, 193–200. https://doi.org/10.1016/j.tifs.2021.02.002

- Munekata, P. E. S., Pérez-Álvarez, J. Á., Pateiro, M., Viuda-Matos, M., Fernández-López, J., Lorenzo, J. M. (2021). Satiety from healthier and functional foods. Trends in Food Science & Technology, 113, 397–410. https://doi.org/10.1016/j.tifs.2021.05.025

- Fan, X., Li, X., Du, L., Li, J., Xu, J., Shi, Z. et al. (2022). The effect of natural plant-based homogenates as additives on the quality of yogurt: A review. Food Bioscience, 49, 101953. https://doi.org/10.1016/j.fbio.2022.101953

- De Zoysa, H. K. S., Waisundara, V. Y.; Martinović, A., Oh, S., Lelieveld, H. (Eds.) (2022). Benefits and risks of organic food. Ensuring Global Food Safety. Academic Press, 197–212. https://doi.org/10.1016/b978-0-12-816011-4.00008-2

- Pashniuk, L. O. (2012). Food industry of ukraine:state, tendencies and perspectives of development. Ekonomіchnii chasopis-XXI, 60–63. Available at: http://dspace.nbuv.gov.ua/bitstream/handle/123456789/48329/18-Pashniuk.pdf?sequence=1

- MOZ Ukrainy predstavylo rekomendatsii zi zdorovoho kharchuvannia (2017). Available at: https://moz.gov.ua/article/news/moz-ukraini-predstavilo-rekomendacii-zi-zdorovogo-harchuvannja

- Misra, N. N., Koubaa, M., Roohinejad, S., Juliano, P., Alpas, H., Inácio, R. S., Saraiva, J. A., Barba, F. J. (2017). Landmarks in the historical development of twenty first century food processing technologies. Food Research International, 97, 318–339. https://doi.org/10.1016/j.foodres.2017.05.001

- Marcus, J. B. (2013). Life Cycle Nutrition: Healthful Eating Throughout the Ages. Culinary Nutrition. Academic Press, 475–543. https://doi.org/10.1016/b978-0-12-391882-6.00011-x

- Ruiz Rodríguez, L. G., Zamora Gasga, V. M., Pescuma, M., Van Nieuwenhove, C., Mozzi, F., Sánchez Burgos, J. A. (2021). Fruits and fruit by-products as sources of bioactive compounds. Benefits and trends of lactic acid fermentation in the development of novel fruit-based functional beverages. Food Research International, 140, 109854. https://doi.org/10.1016/j.foodres.2020.109854

- Mykhailov, V., Zahorulko, A., Zagorulko, A., Liashenko, B., Dudnyk, S. (2021). Method for producing fruit paste using innovative equipment. Acta Innovations, 39, 15–21. https://doi.org/10.32933/actainnovations.39.2

- Silveira, A. C. P. (2015). Thermodynamic and hydrodynamic characterization of the vacuumevaporation process during concentration of dairy products in a falling film evaporator. Food andNutrition. Agrocampus Ouest. Available at: https://tel.archives-ouvertes.fr/tel-01342521

- Kasabova, K., Sabadash, S., Mohutova, V., Volokh, V., Poliakov, A., Lazarieva, T. et al. (2020). Improvement of a scraper heat exchanger for pre-heating plant-based raw materials before concentration. Eastern-European Journal of Enterprise Technologies, 3 (11 (105)), 6–12. https://doi.org/10.15587/1729-4061.2020.202501

- Crespí-Llorens, D., Vicente, P., Viedma, A. (2018). Experimental study of heat transfer to non-Newtonian fluids inside a scraped surface heat exchanger using a generalization method. International Journal of Heat and Mass Transfer, 118, 75–87. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.115

- Cokgezme, O. F., Sabanci, S., Cevik, M., Yildiz, H., Icier, F. (2017). Performance analyses for evaporation of pomegranate juice in ohmic heating assisted vacuum system. Journal of Food Engineering, 207, 1–9. https://doi.org/10.1016/j.jfoodeng.2017.03.015

- Ahmetović, E., Ibrić, N., Kravanja, Z., Grossmann, I. E., Maréchal, F., Čuček, L., Kermani, M. (2018). Simultaneous optimisation and heat integration of evaporation systems including mechanical vapour recompression and background process. Energy, 158, 1160–1191. https://doi.org/10.1016/j.energy.2018.06.046

- Dolores Alvarez, M., Canet, W. (2013). Time-independent and time-dependent rheological characterization of vegetable-based infant purees. Journal of Food Engineering, 114(4), 449–464. https://doi.org/10.1016/j.jfoodeng.2012.08.034

- Cherevko, O., Mikhaylov, V., Zahorulko, A., Zagorulko, A., Gordienko, I. (2021). Development of a thermal-radiation single-drum roll dryer for concentrated food stuff. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 25–32. https://doi.org/10.15587/1729-4061.2021.224990

- Chang, S. K., Alasalvar, C., Shahidi, F. (2016). Review of dried fruits: Phytochemicals, antioxidant efficacies, and health benefits. Journal of Functional Foods, 21, 113–132. https://doi.org/10.1016/j.jff.2015.11.034

- Zahorulko, A., Zagorulko, A., Yancheva, M., Ponomarenko, N., Tesliuk, H., Silchenko, E. et al. (2020). Increasing the efficiency of heat and mass exchange in an improved rotary film evaporator for concentration of fruit-and-berry puree. Eastern-European Journal of Enterprise Technologies, 6(8 (108)), 32–38. https://doi.org/10.15587/1729-4061.2020.218695

- Karam, M. C., Petit, J., Zimmer, D., Baudelaire Djantou, E., Scher, J. (2016). Effects of drying and grinding in production of fruit and vegetable powders: A review. Journal of Food Engineering, 188, 32–49. https://doi.org/10.1016/j.jfoodeng.2016.05.001

- Silva, L. B. da, Queiroz, M. B., Fadini, A. L., Fonseca, R. C. C. da, Germer, S. P. M., Efraim, P. (2016). Chewy candy as a model system to study the influence of polyols and fruit pulp (açai) on texture and sensorial properties. LWT – Food Science and Technology, 65, 268–274. https://doi.org/10.1016/j.lwt.2015.08.006

- Kasabova, K., Zagorulko, A., Zahorulko, A., Shmatchenko, N., Simakova, O., Goriainova, I. et al. (2021). Improving pastille manufacturing technology using the developed multicomponent fruit and berry paste. Eastern-European Journal of Enterprise Technologies, 3(11 (111)), 49–56. https://doi.org/10.15587/1729-4061.2021.231730

- Guan, Q., Xiong, T., Xie, M. (2021). Influence of Probiotic Fermented Fruit and Vegetables on Human Health and the Related Industrial Development Trend. Engineering, 7 (2), 212–218. https://doi.org/10.1016/j.eng.2020.03.018

- Chernenkova, A., Leonova, S., Nikiforova, T., Zagranichnaya, A., Chernenkov, E., Kalugina, O. et al. (2019). The Usage of Biologically Active Raw Materials in Confectionery Products Technology. OnLine Journal of Biological Sciences, 19 (1), 77–91. https://doi.org/10.3844/ojbsci.2019.77.91

- Mardani, M., Yeganehzad, S., Ptichkina, N., Kodatsky, Y., Kliukina, O., Nepovinnykh, N., Naji-Tabasi, S. (2019). Study on foaming, rheological and thermal properties of gelatin-free marshmallow. Food Hydrocolloids, 93, 335–341. https://doi.org/10.1016/j.foodhyd.2019.02.033

- Nepochatykh, T., Sheremet, S. (2018). Ensuring the Quality of the New Fruit and Berry Marmalade by Adding Kelp. Path of Science, 4 (2), 3001–3007. https://doi.org/10.22178/pos.31-6

- Figueroa, L. E., Genovese, D. B. (2019). Fruit jellies enriched with dietary fibre: Development and characterization of a novel functional food product. LWT, 111, 423–428. https://doi.org/10.1016/j.lwt.2019.05.031

- Bashta, A. O., Kovalchuk, V. V. (2014). Rozroblennia sposobu otrymannia zefiru ozdorovchoho pryznachennia. Kharchova promyslovist, 16, 37–41. Available at: http://nbuv.gov.ua/UJRN/Khp_2014_16_10

- Samokhvalova, O. V., Kasabova, K. R., Oliinyk, S. H. (2014). The influence of the enriching additives on the dough structure formation and baked muffins. Eastern-European Journal of Enterprise Technologies, 1 (10 (67)), 32–36. https://doi.org/10.15587/1729-4061.2014.20024

- Samokhvalova, O. V., Chernikova, Yu. O., Oliinyk, S. H., Kasabova, K. R. (2015). The effect of microbial polysaccharides on the properties of wheat flour. Eastern-European Journal of Enterprise Technologies, 6 (10 (77)), 11–15. https://doi.org/10.15587/1729-4061.2015.56177

- Nirmal, N. P., Mereddy, R., Maqsood, S. (2021). Recent developments in emerging technologies for beetroot pigment extraction and its food applications. Food Chemistry, 356, 129611. https://doi.org/10.1016/j.foodchem.2021.129611

- Cherevko, O. I., Maiak, O. A., Kostenko, S. M., Sardarov, A. M. (2019). Experimental and simulation modeling of the heat exchanche process while boiling vegetable juice. Prohresyvni tekhnika ta tekhnolohii kharchovykh vyrobnytstv restorannoho hospodarstva i torhivli, 1 (29), 75–85. Available at: https://repo.btu.kharkov.ua/handle/123456789/298

- Abuova, A. B., Baibatyrov, T. A., Akhmetova, G. K.., Chinarova, E. R. (2015). Primenenie innovatcionnykh tekhnologii v proizvodstve muchnykh konditerskikh izdelii. Evraziiskii Soiuz Uchenykh, 11-3 (20). Available at: https://cyberleninka.ru/article/n/primenenie-innovatsionnyh-tehnologii-v-proizvodstve-muchnyh-konditerskih-izdeliy Last accessed: 16.09.2021

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Aleksey Zagorulko, Kateryna Kasabova, Andrii Zahorulko, Maksym Serik, Olena Bolkhovitina

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.