Development of transesterification model for safe technology of chemical modification of oxidized fats

DOI:

https://doi.org/10.15587/1729-4061.2022.266931Keywords:

chemical modification of fats, catalytic transesterification, potassium glyceroxide, catalyst of fat transesterificationAbstract

The object of research is the process of chemical transesterification of palm olein with increased oxidation indicators in the presence of potassium glyceroxide catalyst.

Transesterification is an important method of fat modification. The use of fats with increased oxidation indicators leads to the deactivation of common catalysts and a decrease in the efficiency of the process. There is a need to increase the dosage of catalysts, increase the process temperature, which negatively affects the product quality.

An alternative transesterification catalyst (potassium glyceroxide) was used for the transesterification of palm olein with increased oxidation indicators.

Palm olein (CAS Number 93334-39-5) with standard indicators was used: melting point 22.4 °C, peroxide value 0.8 ½ O mmol/kg, anisidine value 0.3 c. u. Olein was subjected to heating at a temperature of 90 °C in order to increase oxidation indicators, after which it underwent transesterification. The difference in melting points of the initial and transesterified palm olein was used as a parameter of process efficiency.

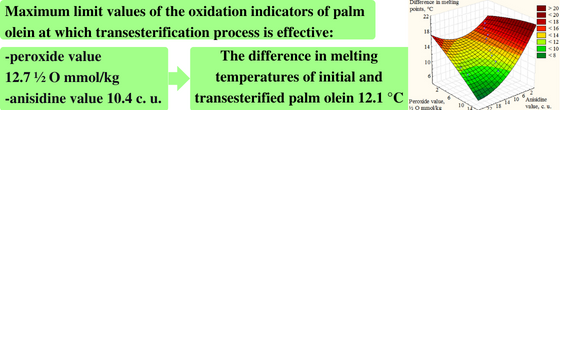

The maximum limit values of the oxidation indicators at which the process is effective are: peroxide value 12.7 ½ O mmol/kg, anisidine value 10.4 c. u. The difference in melting points is 12.1 °C, which indicates the efficiency of the process. The qualitative indicators of the obtained transesterified fat indicate compliance with DSTU 4336 (CAS Number 97593-46-9): melting point 34.5 °C, peroxide value 1.2 ½ O mmol/kg, anisidine value 1.0 c. u.

The results of the research make it possible to use fat with increased oxidation indicators without pretreatment and predict the efficiency of transesterification depending on the fat indicators. This will increase profitability and reduce production waste.

References

- Almazrouei, M., Elagroudy, S., Janajreh, I. (2019). Transesterification of waste cooking oil: Quality assessment via thermogravimetric analysis. Energy Procedia, 158, 2070–2076. doi: https://doi.org/10.1016/j.egypro.2019.01.478

- Bliznjuk, O., Masalitina, N., Mezentseva, I., Novozhylova, T., Korchak, M., Haliasnyi, I. et al. (2022). Development of safe technology of obtaining fatty acid monoglycerides using a new catalyst. Eastern-European Journal of Enterprise Technologies, 2 (6 (116)), 13–18. doi: https://doi.org/10.15587/1729-4061.2022.253655

- Sytnik, N., Kunitsia, E., Kalyna, V., Petukhova, O., Ostapov, K., Ishchuk, V. et al. (2021). Technology development of fatty acids obtaining from soapstok using saponification. Eastern-European Journal of Enterprise Technologies, 5 (6 (113)), 16–23. doi: https://doi.org/10.15587/1729-4061.2021.241942

- Levterov, A. M. (2018). Thermodynamic properties of fatty acid esters in some biodiesel fuels. Functional Materials, 25 (2), 308–312. doi: https://doi.org/10.15407/fm25.02.308

- Zhou, Y., Li, K., Sun, S. (2021). Simultaneous esterification and transesterification of waste phoenix seed oil with a high free fatty acid content using a free lipase catalyst to prepare biodiesel. Biomass and Bioenergy, 144, 105930. doi: https://doi.org/10.1016/j.biombioe.2020.105930

- Korchak, M., Yermakov, S., Maisus, V., Oleksiyko, S., Pukas, V., Zavadskaya, I. (2020). Problems of field contamination when growing energy corn as monoculture. E3S Web of Conferences, 154, 01009. doi: https://doi.org/10.1051/e3sconf/202015401009

- Korchak, M., Yermakov, S., Hutsol, T., Burko, L., Tulej, W. (2021). Features of Weediness of the Field by Root Residues of Corn. Environment. Technologies. Resources. Proceedings of the International Scientific and Practical Conference, 1, 122–126. doi: https://doi.org/10.17770/etr2021vol1.6541

- Popov, O., Taraduda, D., Sobyna, V., Sokolov, D., Dement, M., Pomaza-Ponomarenko, A. (2020). Emergencies at Potentially Dangerous Objects Causing Atmosphere Pollution: Peculiarities of Chemically Hazardous Substances Migration. Studies in Systems, Decision and Control, 151–163. doi: https://doi.org/10.1007/978-3-030-48583-2_10

- Tiutiunyk, V. V., Ivanets, H. V., Tolkunov, I. A., Stetsyuk, E. I. (2018). System approach for readiness assessment units of civil defense to actions at emergency situations. Scientific Bulletin of National Mining University, 1, 99–105. doi: https://doi.org/10.29202/nvngu/2018-1/7

- León-Reina, L., Cabeza, A., Rius, J., Maireles-Torres, P., Alba-Rubio, A. C., López Granados, M. (2013). Structural and surface study of calcium glyceroxide, an active phase for biodiesel production under heterogeneous catalysis. Journal of Catalysis, 300, 30–36. doi: https://doi.org/10.1016/j.jcat.2012.12.016

- Sytnik, N., Demidov, I., Kunitsa, E., Mazaeva, V., Chumak, O. (2016). A study of fat interesterification parameters’ effect on the catalytic reaction activity of potassium glycerate. Eastern-European Journal of Enterprise Technologies, 3 (6 (81)), 33–38. doi: https://doi.org/10.15587/1729-4061.2016.71236

- Suzihaque, M. U. H., Alwi, H., Kalthum Ibrahim, U., Abdullah, S., Haron, N. (2022). Biodiesel production from waste cooking oil: A brief review. Materials Today: Proceedings, 63, S490–S495. doi: https://doi.org/10.1016/j.matpr.2022.04.527

- Carmona-Cabello, M., Saez-Bastante, J., Pinzi, S., Dorado, M. P. (2020). Auxiliary energy-assisted biodiesel production data from solid food waste oil. Data in Brief, 30, 105456. doi: https://doi.org/10.1016/j.dib.2020.105456

- Maddikeri, G. L., Pandit, A. B., Gogate, P. R. (2013). Ultrasound assisted interesterification of waste cooking oil and methyl acetate for biodiesel and triacetin production. Fuel Processing Technology, 116, 241–249. doi: https://doi.org/10.1016/j.fuproc.2013.07.004

- Falowo, O. A., Oladipo, B., Taiwo, A. E., Olaiya, A. T., Oyekola, O. O., Betiku, E. (2022). Green heterogeneous base catalyst from ripe and unripe plantain peels mixture for the transesterification of waste cooking oil. Chemical Engineering Journal Advances, 10, 100293. doi: https://doi.org/10.1016/j.ceja.2022.100293

- Abukhadra, M. R., Soliman, S. R., Bin Jumah, M. N., Othman, S. I., AlHammadi, A. A., Alruhaimi, R. S. et al. (2022). Insight into the sulfonation conditions on the activity of sub-bituminous coal as acidic catalyst during the transesterification of spent corn oil; effect of sonication waves. Sustainable Chemistry and Pharmacy, 27, 100691. doi: https://doi.org/10.1016/j.scp.2022.100691

- Cao, Y., Dhahad, H. A., Esmaeili, H., Razavi, M. (2022). MgO@CNT@K2CO3 as a superior catalyst for biodiesel production from waste edible oil using two-step transesterification process. Process Safety and Environmental Protection, 161, 136–146. doi: https://doi.org/10.1016/j.psep.2022.03.026

- Mercy Nisha Pauline, J., Sivaramakrishnan, R., Pugazhendhi, A., Anbarasan, T., Achary, A. (2021). Transesterification kinetics of waste cooking oil and its diesel engine performance. Fuel, 285, 119108. doi: https://doi.org/10.1016/j.fuel.2020.119108

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Mykola Korchak, Oleksandr Bragin, Olena Petrova, Natalia Shevchuk, Liudmyla Strikha, Serhii Stankevych, Yana Svishchova, Natalia Khimenko, Olesya Filenko, Olena Petukhova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.