Development of technology of snacks with different types of breading for fast food enterprises

DOI:

https://doi.org/10.15587/1729-4061.2022.268905Keywords:

gluten-free breading, "Cold swell" starch, "Klyar" semi-finished product, two-layer breading, freezingAbstract

The object of this study is snack technologies for various types of gluten-free breading for "Fast food" ERI format.

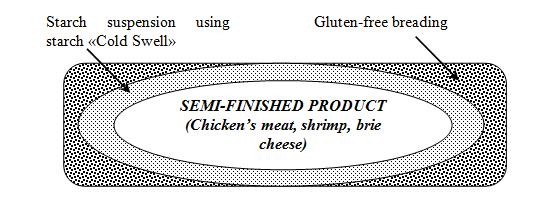

It has been determined that snacks are gaining more and more demand in restaurants of the "Fast food" format. From the point of view of a balanced diet, snack products for fast food are rich in cholesterol with increased amounts of sugar, salt, and gluten protein. In the course of technological testing, components for dry breading were selected: rice flour, extruded oatmeal and corn flakes, sesame seeds. For the manufacture of snacks, the main raw material was chosen – shrimp meat, poultry, soft cheese "Brie". To give the snacks more refined and rich tastes, spices were used: turmeric and ground paprika.

For the most part, the technologies are designed for freezing and subsequent heat treatment (deep-frying). According to this, the specificity of the development of two-layer breading was investigated, namely the development of the "Klyar" semi-finished product and dry breading. The composition of the "Klyar" semi-finished product includes cold-swollen starch "Cold Swell", which is able to quickly swell and form a colloidal suspension.

Due to the functional properties of starch "Cold Swell", the cycle "freezing – heat treatment" took place without significant heat loss. With a starch content of 3.5 % in the breading composition, during their cutting, homogeneity of the main product and breading was observed. Carrying out technological testing, it was determined that the starch content is 3.5 %, the losses during heat treatment are up to 8.0 %, thereby confirming that the properties of starch do not only bind but also hold moisture.

During the study of microbiological indicators, it was determined that frozen snacks are capable of withstanding long-term storage for up to 90 days at a temperature of 18...– 24 °C.

References

- Rumiantseva, I. B., Semanyshyn, S. Ya. (2022). Innovatsiyni tekhnolohiyi v suchasnomu restorannomu biznesi. Tezy dopovidei IV Mizhnarodnoi naukovo-praktychnoi konferentsiyi: Management of socio-economic transformations of business processes: realities and challenges. Mukachevo, 205.

- Carter, R. (1997). Applying Diffusion Theory to Chain Restaurants. Journal of Restaurant & Foodservice Marketing, 2 (3), 37–53. doi: https://doi.org/10.1300/j061v02n03_04

- Trier, C., Fonvig, C. E., Bøjsøe, C., Mollerup, P. M., Gamborg, M., Pedersen, O. et al. (2016). No influence of sugar, snacks and fast food intake on the degree of obesity or treatment effect in childhood obesity. Pediatric Obesity, 11 (6), 506–512. doi: https://doi.org/10.1111/ijpo.12094

- Sen, S., Antara, N., Sen, S. (2019). Factors influencing consumers’ to Take Ready-made Frozen Food. Current Psychology, 40 (6), 2634–2643. doi: https://doi.org/10.1007/s12144-019-00201-4

- Makroo, H. A., Talukdar, P., Hmar, B. Z., Das, P. P. (2022). Frozen Foods. Shelf Life and Food Safety, 155–164. doi: https://doi.org/10.1201/9781003091677-9

- Wojeicchowski, J. P., Siqueira, G. L. De A. De, Lacerda, L. G., Schnitzler, E., Demiate, I. M. (2018). Physicochemical, structural and thermal properties of oxidized, acetylated and dual-modified common bean (Phaseolus vulgaris L.) starch. Food Science and Technology, 38 (2), 318–327. doi: https://doi.org/10.1590/1678-457x.04117

- Gamonpilas, C., Pongjaruvat, W., Methacanon, P., Seetapan, N., Fuongfuchat, A., Klaikherd, A. (2013). Effects of cross-linked tapioca starches on batter viscosity and oil absorption in deep-fried breaded chicken strips. Journal of Food Engineering, 114 (2), 262–268. doi: https://doi.org/10.1016/j.jfoodeng.2012.08.008

- Pichkur, V. Ya., Lysyi, O. V., Hrabovska, O. V., Kovbasa, V. M. (2014). Doslidzhennia osnovnykh fizyko-khimichnykh vlastyvostei nabukhaiuchykh vydiv krokhmaliu. Naukovi pratsi [Odeskoi natsionalnoi akademiyi kharchovykh tekhnolohii], 46 (2), 148–152. Available at: http://nbuv.gov.ua/UJRN/Np_2014_46%282%29__39

- Kupkanchanakul, W., Yamaguchi, T., Naivikul, O. (2019). Gluten-Free Rice Breading Using Composited Rice Flour and Pre-Germinated Brown Rice Flour for Health Benefits. Journal of Nutritional Science and Vitaminology, 65, S206–S211. doi: https://doi.org/10.3177/jnsv.65.s206

- Liu, Y., Zhang, Z., Hu, L. (2021). High efficient freeze-drying technology in food industry. Critical Reviews in Food Science and Nutrition, 62 (12), 3370–3388. doi: https://doi.org/10.1080/10408398.2020.1865261

- Perekhrest, I. M. (2009). Neperenosymist hliutenu bez tseliakiyi – rekomendatsiyi do diietoterapiyi dlia ditei. Epidemiology and Community Health, 63, 233–238.

- Vilca-Cáceres, V. A., Gómez-Pacco, N. L., Vargas Callo, W. R. (2020). Nutritional quality and levels of acceptability of innovative fish-based products: breaded and kamaboko. Journal of the Selva Andina Research Society, 11 (2), 153–166. Available at: http://www.scielo.org.bo/scielo.php?pid=S2072-92942020000200010&script=sci_abstract&tlng=en

- Hill, H. (2021). Utilization of Dry Beans and Other Pulses as Ingredients in Diverse Food Products. Dry Beans and Pulses, 307–329. doi: https://doi.org/10.1002/9781119776802.ch12

- Shinkaruk, M. I., Kravchuk, N. M. (2014). Opredelenie vliyaniya soevoj muki v obogashchennyh panirovochnyh smesyah dlya zharki na temperaturu frityurnogo zhira. Scientific Works of University of Food Technologies, LXI, 78–83. Available at: http://uft-plovdiv.bg/site_files/file/scienwork/scienworks_2014/docs/part_2/15_Shinkaruk_Kravchuk.pdf

- Horalchuk, A. B., Pyvovarov, P. P., Hrynchenko, O. O. et al. (2006). Reolohichni metody doslidzhennia syrovyny i kharchovykh produktiv ta avtomatyzatsiya rozrakhunkiv reolohichnykh kharakterystyk. Kharkiv, 63.

- Krahmal holodnogo nabuhaniya COLDSWELL 5771 (Е1422). Available at: https://milk.ingredients.pro/ingredients/8407/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Svitlana Andrieieva, Maryna Kolesnikova, Olha Grinchenko, Svitlana Iurchenko, Aliona Dikhtyar

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.