Development of technology for obtaining fat compositions with increased oxidative stability

DOI:

https://doi.org/10.15587/1729-4061.2023.272210Keywords:

fat composition, oxidative stability, induction period, oxidation inhibitor, free radical processAbstract

The object of research is the process of fat oxidation at elevated and standard temperatures.

Fats are used in chemical, pharmaceutical, food and other industries. Oxidative deterioration changes the composition of fats, reduces the efficiency of chemical reactions involving fats and the quality of final products. An urgent task is to increase the oxidative stability of fats.

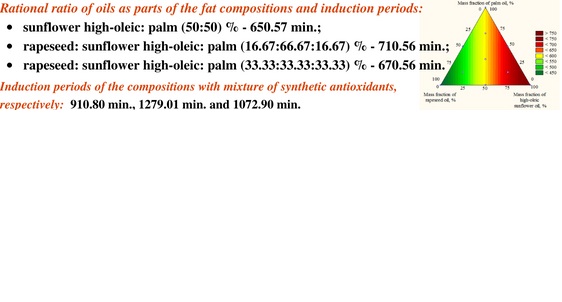

The oxidative stability of fat compositions based on rapeseed, high-oleic sunflower and palm oils by the induction period at a temperature of 110 °C was investigated. The induction periods of the initial oils were 408.48 min., 795.87 min. and 630.2 min., respectively. Rational ratios of oils in the compositions were found: high-oleic sunflower: palm (50:50) %; rapeseed: high-oleic sunflower: palm (16.67:66.67:16.67) %; rapeseed: high-oleic sunflower: palm (33.33:33.33:33.33) %. The induction periods of the mixtures are 650.57 min., 710.56 min. and 670.56 min., respectively.

The increase in the oxidative stability of the developed compositions using the mixture of synthetic antioxidants (butylhydroxyanisole, butylhydroxytoluene and tert-butylhydroquinone) in an amount of 300 mg/kg of fat mixture was studied. The induction periods of the developed compositions were 910.80 min., 1279.01 min. and 1072.90 min., respectively.

The physicochemical parameters of compositions with the addition of antioxidants after 5 months of storage at a temperature of (20±2) °C were determined. The peroxide values of the compositions were 5.65; 3.28; 4.50 ½ O mmol/kg, respectively.

The research results make it possible to produce fats with increased oxidative stability and necessary properties, to predict induction periods of fat compositions depending on the concentrations of components. This will increase the profitability of production and the quality of fats obtained

References

- Chernukha, A., Teslenko, A., Kovalov, P., Bezuglov, O. (2020). Mathematical Modeling of Fire-Proof Efficiency of Coatings Based on Silicate Composition. Materials Science Forum, 1006, 70–75. doi: https://doi.org/10.4028/www.scientific.net/msf.1006.70

- Sytnik, N., Kunitsia, E., Mazaeva, V., Chernukha, A., Kovalov, P., Grigorenko, N. et al. (2020). Rational parameters of waxes obtaining from oil winterization waste. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 29–35. doi: https://doi.org/10.15587/1729-4061.2020.219602

- Ghosh, M., Upadhyay, R., Mahato, D. K., Mishra, H. N. (2019). Kinetics of lipid oxidation in omega fatty acids rich blends of sunflower and sesame oils using Rancimat. Food Chemistry, 272, 471–477. doi: https://doi.org/10.1016/j.foodchem.2018.08.072

- Petik, I., Belinska, A., Kunitsia, E., Bochkarev, S., Ovsiannikova, T., Kalyna, V. et al. (2021). Processing of ethanol-containing waste of oil neutralization in the technology of hand cleaning paste. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 23–29. doi: https://doi.org/10.15587/1729-4061.2021.225233

- Sytnik, N., Kunitsa, E., Mazaeva, V., Chernukha, A., Bezuglov, O., Bogatov, O. et al. (2020). Determination of the influence of natural antioxidant concentrations on the shelf life of sunflower oil. Eastern-European Journal of Enterprise Technologies, 4 (11 (106)), 55–62. doi: https://doi.org/10.15587/1729-4061.2020.209000

- Borsato, D., Cini, J. R. de M., Silva, H. C. da, Coppo, R. L., Angilelli, K. G., Moreira, I., Maia, E. C. R. (2014). Oxidation kinetics of biodiesel from soybean mixed with synthetic antioxidants BHA, BHT and TBHQ: Determination of activation energy. Fuel Processing Technology, 127, 111–116. doi: https://doi.org/10.1016/j.fuproc.2014.05.033

- de Jesus, J. H. F., Ferreira, A. P. G., Szilágyi, I. M., Cavalheiro, E. T. G. (2020). Thermal behavior and polymorphism of the antioxidants: BHA, BHT and TBHQ. Fuel, 278, 118298. doi: https://doi.org/10.1016/j.fuel.2020.118298

- Sytnik, N., Kunitsia, E., Mazaeva, V., Chernukha, A., Ostapov, K., Borodych, P. et al. (2021). Establishing rational conditions for obtaining potassium glycerate. Eastern-European Journal of Enterprise Technologies, 3 (6 (111)), 12–18. doi: https://doi.org/10.15587/1729-4061.2021.231449

- Norazlina, M. R., Jahurul, M. H. A., Hasmadi, M., Mansoor, A. H., Norliza, J., Patricia, M. et al. (2021). Trends in blending vegetable fats and oils for cocoa butter alternative application: A review. Trends in Food Science & Technology, 116, 102–114. doi: https://doi.org/10.1016/j.tifs.2021.07.016

- Aladedunye, F., Przybylski, R. (2013). Frying stability of high oleic sunflower oils as affected by composition of tocopherol isomers and linoleic acid content. Food Chemistry, 141 (3), 2373–2378. doi: https://doi.org/10.1016/j.foodchem.2013.05.061

- Serqueira, D. S., Fernandes, D. M., Cunha, R. R., Squissato, A. L., Santos, D. Q., Richter, E. M., Munoz, R. A. A. (2014). Influence of blending soybean, sunflower, colza, corn, cottonseed, and residual cooking oil methyl biodiesels on the oxidation stability. Fuel, 118, 16–20. doi: https://doi.org/10.1016/j.fuel.2013.10.028

- Al-Sabaeei, A. M., Al-Fakih, A., Noura, S., Yaghoubi, E., Alaloul, W., Al-Mansob, R. A. et al. (2022). Utilization of palm oil and its by-products in bio-asphalt and bio-concrete mixtures: A review. Construction and Building Materials, 337, 127552. doi: https://doi.org/10.1016/j.conbuildmat.2022.127552

- Mikołajczak, N., Tańska, M., Konopka, I. (2021). The effect of the hydrophilic and lipophilic herbal extracts on the oxidative stability of cooking plant oils during low- and high-temperature heating. NFS Journal, 25, 41–50. doi: https://doi.org/10.1016/j.nfs.2021.10.002

- Chen, B., Su, Z., Du, Z., Ma, M., Zhang, J., Tang, C. (2022). A new type of mixed vegetable insulating oil with better kinematic viscosity and oxidation stability. Journal of Molecular Liquids, 360, 119512. doi: https://doi.org/10.1016/j.molliq.2022.119512

- Kasprzak, M., Rudzińska, M., Przybylski, R., Kmiecik, D., Siger, A., Olejnik, A. (2020). The degradation of bioactive compounds and formation of their oxidation derivatives in refined rapeseed oil during heating in model system. LWT, 123, 109078. doi: https://doi.org/10.1016/j.lwt.2020.109078

- Jadhav, H. B., Gogate, P. R., Waghmare, J. T., Annapure, U. S. (2022). Comparative assessment of thermo-oxidative stability of palm oil designer lipid and palm oil blends as frying medium. Applied Food Research, 2 (1), 100039. doi: https://doi.org/10.1016/j.afres.2021.100039

- De Leonardis, A., Macciola, V. (2012). Heat-oxidation stability of palm oil blended with extra virgin olive oil. Food Chemistry, 135 (3), 1769–1776. doi: https://doi.org/10.1016/j.foodchem.2012.06.046

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Dmytro Saveliev, Oleksandr Hryhorenko, Evgeniia Mykhailova, Mikhail Kravtsov, Oleg Kostyrkin, Anatolii Nikitin, Valentyn Romaniuk, Oleksandr Smolkov, Ivan Meshcheriakov, Volodymyr Bahlai

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.