Determining the influence of pre-preparation of blueberries (Vaccinium corymbosum L.) on the total duration of drying

DOI:

https://doi.org/10.15587/1729-4061.2023.276097Keywords:

convective drying, hygrothermal treatment, infrared radiation, moisture content, mode parametersAbstract

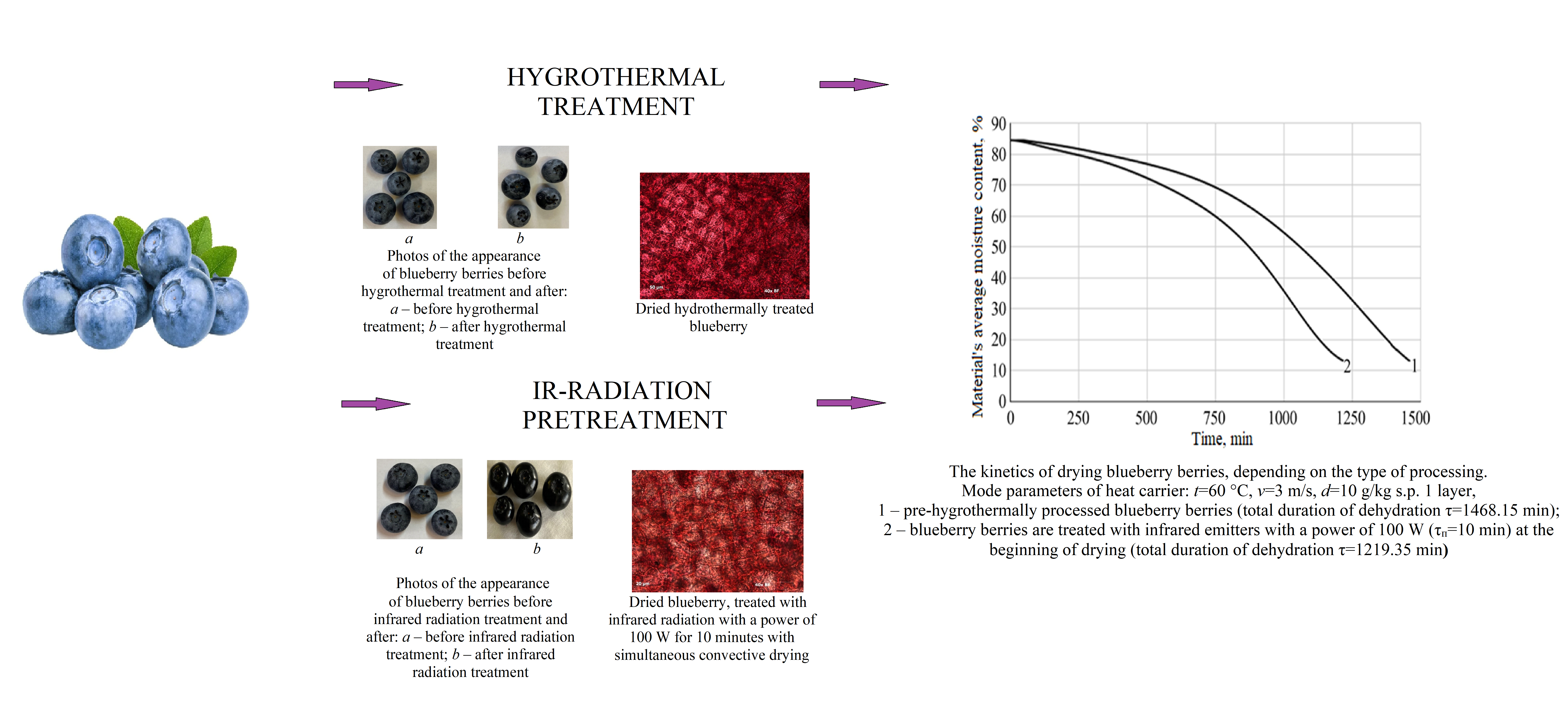

Comprehensive studies into the influence of various types of preliminary preparation of blueberry berries for drying have established the amount of wax coating, color, and the total duration of dehydration of raw materials. A comparison of 2 types of preliminary preparation was made: hygrothermal treatment and infrared radiation treatment directly during drying. It was established that after treatment with infrared radiation, 53 times more wax plaque came off the berries than after hygrothermal treatment. Microscopic studies of sections of the parenchymal part of berries recorded the state of the cell membranes and the color of the raw materials without prior processing, with pretreatment, and after drying. It was found that berries dried without pretreatment (mode parameters of heat carrier: t=70 °C, v=2 m/s, d=10 g/kg dry air. Win=85 %, ) have partially destroyed cell membranes but the color of the dried material is preserved to the maximum. It was observed that the berries after hygrothermal treatment have partially destroyed parts of the cell membrane, which makes it possible to more intensively release moisture from the material after drying, the maximum color of the product is also preserved. In berries, after treatment with infrared radiation of 100 W for 10 minutes, the cells remain convex with partial destruction of the shell of some cells but, after pretreatment, the intensity of color decreases. Studies into the kinetics of drying blueberry berries have confirmed that the use of infrared radiation with a capacity of 100 W for 10 minutes with simultaneous drying under the regime parameters of the heat carrier t=60 °C, v=3 m/s, d=10 g/kg dry air. makes it possible to reduce wax coating on blueberry berries and to intensify thermal moisture exchange during drying of berries better than using hygrothermal treatment

References

- Antal, T. (2021). Effect of different drying techniques on the drying time and energy of blueberry. Analecta Technica Szegedinensia, 15 (1), 23–30. doi: https://doi.org/10.14232/analecta.2021.1.23-30

- Satanina, V. (2011). Optimization of Hydrothermodynamic Technology for Blueberry Food Processing. Nova Scotia. Available at: https://central.bac-lac.gc.ca/.item?id=TC-NSHD-14347&op=pdf&app=Library&oclc_number=870856372

- Loypimai, P., Paewboonsom, S., Damerow, L., Blanke, M. M. (2017). The wax bloom on blueberry: Application of luster sensor technology to assess glossiness and the effect of polishing as a fruit quality parameter. Journal of Applied Botany and Food Quality, 90, 154–158. doi: https://doi.org/10.5073/JABFQ.2017.090.019

- Albrigo, L. G., Lyrene, P. M., Freeman, B. (1980). Waxes and Other Surface Characteristics of Fruit and Leaves of Native Vaccinium elliotti Chapm.1. Journal of the American Society for Horticultural Science, 105 (2), 230–235. doi: https://doi.org/10.21273/jashs.105.2.230

- Silich, A. A., Zozulevich, B. V., Popovskiy, V. G. (1982). Sushka plodov i vinograda v tunnel'nykh sushilkakh. Moscow: Legkaya i pischevaya promyshlennost', 80.

- Petrova, Zh. O., Sniezhkin, Yu. F. (2018). Enerhoefektyvni teplotekhnolohiyi pererobky funktsionalnoi syrovyny. Kyiv: Nauk. dumka, 192.

- Petrova, Zh., Slobodianiuk, K., Grakov, O. (2022). Theoretical analysis of the current state of processing blueberry berries by known drying methods. Scientific Works of NUFT, 28 (3), 123–143. Available at: http://nbuv.gov.ua/UJRN/Npnukht_2022_28_3_13

- Slobodianiuk, K. S., Hrakov, O. P. (2021). Determination of the mass fraction of moisture of blueberry fruits by the drying method to a constant weight. Zbirnyk tez dopovidei ХХIХ vseukrainskoi naukovo-praktychnoi konferentsiyi studentiv, aspirantiv i molodykh vchenykh ”Obladnannia khimichnykh vyrobnytstv i pidpryiemstv budivelnykh materialiv”. Kyiv: «KPI im. Ihoria Sikorskoho», 8–10.

- Pohozhykh, M. I., Pak, A. O. (2015). Enerhoefektyvni sposoby pererobky kharchovoi syrovyny: sushinnia plodovo-yahidnoi syrovyny. Kharkiv: KhDUKhT, 159.

- Sun, Y., Zhang, M., Mujumdar, A. (2019). Berry Drying: Mechanism, Pretreatment, Drying Technology, Nutrient Preservation, and Mathematical Models. Food Engineering Reviews, 11 (2), 61–77. doi: https://doi.org/10.1007/s12393-019-9188-3

- Grochowski, D. M., Skalicka-Woźniak, K., Orhan, I. E., Xiao, J., Locatelli, M., Piwowarski, J. P. et al. (2017). A comprehensive review of agrimoniin. Annals of the New York Academy of Sciences, 1401 (1), 166–180. doi: https://doi.org/10.1111/nyas.13421

- Skrovankova, S., Sumczynski, D., Mlcek, J., Jurikova, T., Sochor, J. (2015). Bioactive Compounds and Antioxidant Activity in Different Types of Berries. International Journal of Molecular Sciences, 16 (10), 24673–24706. doi: https://doi.org/10.3390/ijms161024673

- An, K., Fu, M., Zhang, H., Tang, D., Xu, Y., Xiao, G. (2019). Effect of ethyl oleate pretreatment on blueberry (Vaccinium corymbosum L.): drying kinetics, antioxidant activity, and structure of wax layer. Journal of Food Science and Technology, 56 (2), 783–791. doi: https://doi.org/10.1007/s13197-018-3538-7

- Munzenmayer, P., Ulloa, J., Pinto, M., Ramirez, C., Valencia, P., Simpson, R., Almonacid, S. (2020). Freeze-Drying of Blueberries: Effects of Carbon Dioxide (CO2) Laser Perforation as Skin Pretreatment to Improve Mass Transfer, Primary Drying Time, and Quality. Foods, 9 (2), 211. doi: https://doi.org/10.3390/foods9020211

- Liu, Z.-L., Xie, L., Zielinska, M., Pan, Z., Deng, L.-Z., Zhang, J.-S. et al. (2022). Improvement of drying efficiency and quality attributes of blueberries using innovative far-infrared radiation heating assisted pulsed vacuum drying (FIR-PVD). Innovative Food Science & Emerging Technologies, 77, 102948. doi: https://doi.org/10.1016/j.ifset.2022.102948

- Wang, J., Law, C.-L., Nema, P. K., Zhao, J.-H., Liu, Z.-L., Deng, L.-Z. et al. (2018). Pulsed vacuum drying enhances drying kinetics and quality of lemon slices. Journal of Food Engineering, 224, 129–138. doi: https://doi.org/10.1016/j.jfoodeng.2018.01.002

- Yu, Y., Jin, T. Z., Xiao, G. (2017). Effects of pulsed electric fields pretreatment and drying method on drying characteristics and nutritive quality of blueberries. Journal of Food Processing and Preservation, 41 (6), e13303. doi: https://doi.org/10.1111/jfpp.13303

- Yu, Y., Jin, T. Z., Fan, X., Xu, Y. (2017). Osmotic dehydration of blueberries pretreated with pulsed electric fields: Effects on dehydration kinetics, and microbiological and nutritional qualities. Drying Technology, 35 (13), 1543–1551. doi: https://doi.org/10.1080/07373937.2016.1260583

- Petrova, Zh. A., Slobodyanyuk, E. S. (2019). Energy-Efficient Modes of Drying of Colloidal Capillary-Porous Materials. Journal of Engineering Physics and Thermophysics, 92 (5), 1231–1238. doi: https://doi.org/10.1007/s10891-019-02038-x

- Sniezhkin, Yu. F., Petrova, Zh. O., Paziuk, V. M. (2012). Hidrotermichna obrobka funktsionalnoi syrovyny. Naukovi pratsi, 1 (41), 13–17.

- Krishnamurthy, K., Khurana, H. K., Soojin, J., Irudayaraj, J., Demirci, A. (2008). Infrared Heating in Food Processing: An Overview. Comprehensive Reviews in Food Science and Food Safety, 7 (1), 2–13. doi: https://doi.org/10.1111/j.1541-4337.2007.00024.x

- Burdo, O. H., Terziev, S. H., Ruzhytska, N. V., Borshch, A. A. (2011). Kinetyka ICh-sushinnia shlamu kavy. Kharchova nauka i tekhnolohiya, 4 (17), 96–99. Available at: http://nbuv.gov.ua/UJRN/Khnit_2011_4_34

- Sniezhkin, Yu. F., Petrova, Zh. O., Samoilenko, K. M., Slobodianiuk, K. S. (2022). Teplomasoobminni protsesy otrymannia kombinovanykh funktsionalnykh poroshkiv. Kyiv: Tropea, 148.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Zhanna Petrova, Kateryna Slobodianiuk, Oleksii Grakov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.