Improving the manufacturing technology of sensing gas sensors based on zinc oxide by using the method of magnetron sputtering on direct current

DOI:

https://doi.org/10.15587/1729-4061.2023.277428Keywords:

zinc oxide, gas sensor, magnetron sputtering, sensitivity reaction, target gasAbstract

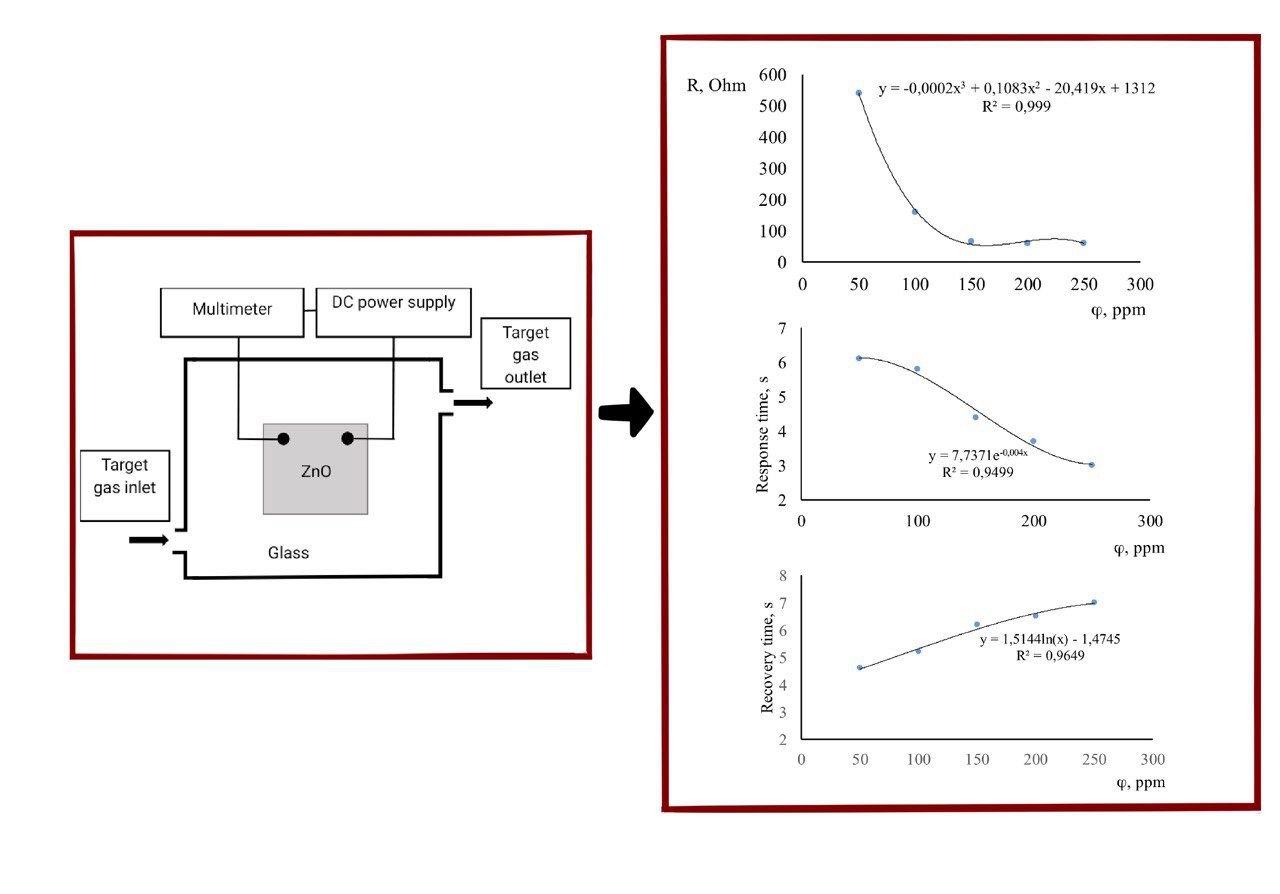

A gas sensor based on zinc oxide obtained by magnetron spraying at direct current was investigated. There are methods of deposition of zinc oxide nanostructures such as thermal evaporation, chemical vapor deposition, organometallic chemical vapor deposition, magnetron sputtering, pulsed laser deposition, and hydrothermal process. The least investigated is magnetron sputtering. To obtain films, a vacuum unit VUP-5M with an original material-saving magnetron was used. Studies into the sensitivity and speed of the gas sensor based on ZnO with respect to the target gas – ethanol of different concentrations – were carried out. The resulting experimental dependences of the sensitivity of the gas sensor on the concentration of the target gas demonstrate that with increasing concentration of the target gas, the resistance decreased while the sensitivity of the sample increased. It was established that the change in the resistance of the test sample is proportional to the change in the concentration of the target gas. After the sensor surface becomes saturated with adsorbed molecules, the resistance no longer decreases, even if the gas concentration continues to increase. The reaction of the gas sensor to the target gas – ethanol – at concentrations above 150 ppm was almost absent. The time required to achieve the maximum response value should be lower at higher target gas concentrations. Sensitivity reaction repeatability studies were conducted to measure the resistance of a gas sensor based on ZnO in a target gas atmosphere with a concentration of 150 ppm. It was found that the gas sensor demonstrates excellent stability and consistent sensitivity reaction when re-exposed to the target gas – ethanol. It was established that the reaction time of a gas sensor based on ZnO to the target gas at each repeated exposure does not exceed 10 s. This repeatability index allows us to assert the stability of the ZnO-based gas sensor in an ethanol atmosphere under standard conditions

References

- Vambol, S., Vambol, V., Sychikova, Y., Deyneko, N. (2017). Analysis of the ways to provide ecological safety for the products of nanotechnologies throughout their life cycle. Eastern-European Journal of Enterprise Technologies, 1 (10 (85)), 27–36. doi: https://doi.org/10.15587/1729-4061.2017.85847

- Semko, A., Rusanova, O., Kazak, O., Beskrovnaya, M., Vinogradov, S., Gricina, I. (2015). The use of pulsed high-speed liquid jet for putting out gas blow-out. The International Journal of Multiphysics, 9 (1), 9–20. doi: https://doi.org/10.1260/1750-9548.9.1.9

- Popov, O., Іatsyshyn, A., Kovach, V., Artemchuk, V., Taraduda, D., Sobyna, V. et al. (2018). Conceptual Approaches for Development of Informational and Analytical Expert System for Assessing the NPP impact on the Environment. Nuclear and Radiation Safety, 3 (79), 56–65. doi: https://doi.org/10.32918/nrs.2018.3(79).09

- Dubinin, D., Korytchenko, K., Lisnyak, A., Hrytsyna, I., Trigub, V. (2017). Numerical simulation of the creation of a fire fighting barrier using an explosion of a combustible charge. Eastern-European Journal of Enterprise Technologies, 6 (10 (90)), 11–16. doi: https://doi.org/10.15587/1729-4061.2017.114504

- Popov, O., Iatsyshyn, A., Kovach, V., Artemchuk, V., Taraduda, D., Sobyna, V. et al. (2019). Physical Features of Pollutants Spread in the Air During the Emergency at NPPs. Nuclear and Radiation Safety, 4 (84), 88–98. doi: https://doi.org/10.32918/nrs.2019.4(84).11

- Kondratenko, O., Vambol, S., Strokov, O., Avramenko, A. (2015). Mathematical model of the efficiency of diesel particulate matter filter. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 6, 55–61.

- Deyneko, N., Yeremenko, S., Kamyshentsev, G., Kryvulkin, I., Matiushenko, M., Myroshnyk, O. et al. (2021). Development of a method for obtaining a CdS/CdTe/Cu/Au module on a flexible substrate designed for backup supplying systems prevention of emergency situations. Eastern-European Journal of Enterprise Technologies, 1 (5 (109)), 31–36. doi: https://doi.org/10.15587/1729-4061.2021.225694

- Neshpor, O., Deyneko, N., Ponomarenko, R., Maiboroda, A., Kropyva, M., Blyashenko, O. et al. (2022). Optimization of the technology for designing sensitive gas sensors based on zinc oxide using a sol-gel method. Eastern-European Journal of Enterprise Technologies, 4 (5 (118)), 30–36. doi: https://doi.org/10.15587/1729-4061.2022.263686

- Wales, D. J., Grand, J., Ting, V. P., Burke, R. D., Edler, K. J., Bowen, C. R. et al. (2015). Gas sensing using porous materials for automotive applications. Chemical Society Reviews, 44 (13), 4290–4321. doi: https://doi.org/10.1039/c5cs00040h

- Wetchakun, K., Samerjai, T., Tamaekong, N., Liewhiran, C., Siriwong, C., Kruefu, V. et al. (2011). Semiconducting metal oxides as sensors for environmentally hazardous gases. Sensors and Actuators B: Chemical, 160 (1), 580–591. doi: https://doi.org/10.1016/j.snb.2011.08.032

- Zhang, Y., Li, D., Qin, L., Zhao, P., Liu, F., Chuai, X. et al. (2018). Preparation and gas sensing properties of hierarchical leaf-like SnO2 materials. Sensors and Actuators B: Chemical, 255, 2944–2951. doi: https://doi.org/10.1016/j.snb.2017.09.115

- Nunes, D., Pimentel, A., Santos, L., Barquinha, P., Pereira, L., Fortunato, E., Martins, R. (2019). Synthesis, design, and morphology of metal oxide nanostructures. Metal Oxide Nanostructures, 21–57. doi: https://doi.org/10.1016/b978-0-12-811512-1.00002-3

- Saboor, A., Shah, S. M., Hussain, H. (2019). Band gap tuning and applications of ZnO nanorods in hybrid solar cell: Ag-doped verses Nd-doped ZnO nanorods. Materials Science in Semiconductor Processing, 93, 215–225. doi: https://doi.org/10.1016/j.mssp.2019.01.009

- Shaikh, S. K., Ganbavale, V. V., Mohite, S. V., Patil, U. M., Rajpure, K. Y. (2018). ZnO nanorod based highly selective visible blind ultra-violet photodetector and highly sensitive NO2 gas sensor. Superlattices and Microstructures, 120, 170–186. doi: https://doi.org/10.1016/j.spmi.2018.05.021

- Kumar, M., Singh Bhati, V., Ranwa, S., Singh, J., kumar, M. (2017). Pd/ZnO nanorods based sensor for highly selective detection of extremely low concentration hydrogen. Scientific Reports, 7 (1). doi: https://doi.org/10.1038/s41598-017-00362-x

- Jing, Z., Zhan, J. (2008). Fabrication and Gas-Sensing Properties of Porous ZnO Nanoplates. Advanced Materials, 20 (23), 4547–4551. doi: https://doi.org/10.1002/adma.200800243

- Jabeen, M., Iqbal, A., Kumar, R. V., Ahmed, M. (2019). Pd-doped zinc oxide nanostructures for liquefied petroleum gas detection at low temperature. Sensing and Bio-Sensing Research, 25, 100293. doi: https://doi.org/10.1016/j.sbsr.2019.100293

- Patial, P., Deshwal, M. (2022). A platinum-doped ZnO-based LPG sensor with high sensitivity. Materials Today: Proceedings, 48, 1201–1204. doi: https://doi.org/10.1016/j.matpr.2021.08.245

- Deng, X., Sang, S., Li, P., Li, G., Gao, F., Sun, Y. et al. (2013). Preparation, Characterization, and Mechanistic Understanding of Pd-Decorated ZnO Nanowires for Ethanol Sensing. Journal of Nanomaterials, 2013, 1–8. doi: https://doi.org/10.1155/2013/297676

- Roy, S., Banerjee, N., Sarkar, C. K., Bhattacharyya, P. (2013). Development of an ethanol sensor based on CBD grown ZnO nanorods. Solid-State Electronics, 87, 43–50. doi: https://doi.org/10.1016/j.sse.2013.05.003

- Aldosary, A. F., Shar, M. A., AlQahtani, H. R. (2022). High-sensitivity detection of ethane and ethylene using gamma-irradiated ZnO chemiresistors. Measurement: Sensors, 24, 100600. doi: https://doi.org/10.1016/j.measen.2022.100600

- Choopun, S., Hongsith, N., Mangkorntong, P., Mangkorntong, N. (2007). Zinc oxide nanobelts by RF sputtering for ethanol sensor. Physica E: Low-Dimensional Systems and Nanostructures, 39 (1), 53–56. doi: https://doi.org/10.1016/j.physe.2006.12.053

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Alona Miasoiedova, Natalia Minska, Roman Shevchenko, Olena Azarenkо, Viktoriia Lukashenko, Oksana Kyrychenko, Oleh Zemlianskyi, Larisa Trefilova, Gennady Kamyshentsev, Roman Melezhyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.