Determining loading patterns in the bearing structure of a railroad flatcar with a floor made from sandwich panels

DOI:

https://doi.org/10.15587/1729-4061.2023.278267Keywords:

railroad car, sandwich panel, dynamic loading of the railroad car, strength of frame structure, safety of goodsAbstract

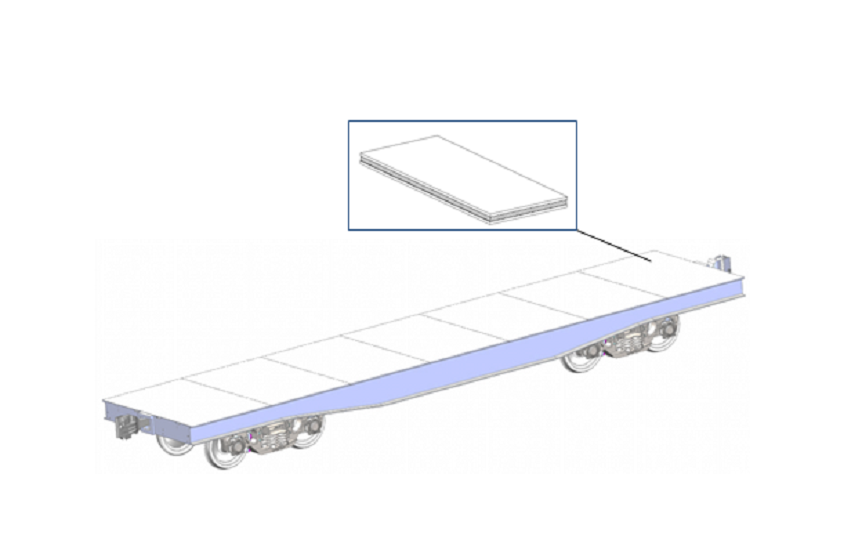

The object of research is the processes of emergence, perception, and redistribution of loads in the supporting structure of a flatcar with a floor made of sandwich panels.

To reduce the impact of dynamic loads on the supporting structure of a flatcar, as well as the safety of goods transported in it, it is proposed to manufacture floors from sandwich panels.

Within the framework of the study, mathematical modeling of the dynamic load on a flatcar when it runs in a loaded state was carried out. It was found that, taking into account the proposed solution, the accelerations acting on the supporting structure of a flatcar are reduced by 8.4 % compared to the typical one. At the same time, accelerations acting on cargo placed on a flatbed car are reduced by 11.7 %. The results of calculating the strength of sandwich panels, when arranged on a flatcar, proved the feasibility of the proposed improvement. The main indicators of dynamics of the improved flatcar structure operated in an empty state were determined. It was established that the flatcar movement is assessed as "good".

A feature of the results reported here is that the improved supporting structure of a flatcar contributes not only to reducing its dynamic load but also to improving the safety of transported cargoes.

The scope of practical application of the results is the engineering industry, in particular, railroad transport. The condition for the practical application of the research results is the use of energy-absorbing material in the structure of sandwich panels.

The study could contribute to devising recommendations regarding the design of modern structures of railroad vehicles and increasing the efficiency of the functioning of the transportation industry

References

- Nerubatskyi, V., Plakhtii, O., Hordiienko, D. (2022). Adaptive Modulation Frequency Selection System in Power Active Filter. 2022 IEEE 8th International Conference on Energy Smart Systems (ESS). doi: https://doi.org/10.1109/ess57819.2022.9969261

- Nerubatskyi, V., Plakhtii, O., Hordiienko, D. (2022). Improving the energy efficiency of traction power supply systems by means the implementation of alternative power sources. Transport Means 2022. Part I. Proceedings of the 26th International Scientific Conference, 459–464. Available at: https://www.ebooks.ktu.lt/eb/1610/transport-means-2022-part-i-proceedings-of-the-26th-international-scientific-conference/

- Nerubatskyi, V., Plakhtii, O., Hordiienko, D. (2022). Efficiency Analysis of DC-DC Converter with Pulse-Width and Pulse-Frequency Modulation. 2022 IEEE 41st International Conference on Electronics and Nanotechnology (ELNANO). doi: https://doi.org/10.1109/elnano54667.2022.9926762

- Lewandowski, K. (2006). Nadwozia wymienne (swap body) w bezterminalowym systemie transportu szynowego. Sistemy transportowe, 6, 53–55. Available at: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BGPK-1398-5437/c/Lewandowski.pdf

- Chuan-jin, O., Bing-tao, L. (2020). Research and application of new multimodal transport equipment-swap bodies in China. E3S Web of Conferences, 145, 02001. doi: https://doi.org/10.1051/e3sconf/202014502001

- Šťastniak, P., Kurčík, P., Pavlík, A. (2018). Design of a new railway wagon for intermodal transport with the adaptable loading platform. MATEC Web of Conferences, 235, 00030. doi: https://doi.org/10.1051/matecconf/201823500030

- Dižo, J., Blatnický, M., Steišūnas, S., Skočilasová, B. (2018). Assessment of a rail vehicle running with the damaged wheel on a ride comfort for passengers. MATEC Web of Conferences, 157, 03004. doi: https://doi.org/10.1051/matecconf/201815703004

- Harak, S. S., Sharma, S. C., Harsha, S. P. (2014). Structural Dynamic Analysis of Freight Railway Wagon Using Finite Element Method. Procedia Materials Science, 6, 1891–1898. doi: https://doi.org/10.1016/j.mspro.2014.07.221

- Fomin, O., Gorbunov, M., Lovska, A., Gerlici, J., Kravchenko, K. (2021). Dynamics and Strength of Circular Tube Open Wagons with Aluminum Foam Filled Center Sills. Materials, 14 (8), 1915. doi: https://doi.org/10.3390/ma14081915

- Pɫaczek, M., Wróbel, A., Buchacz, A. (2016). A concept of technology for freight wagons modernization. IOP Conference Series: Materials Science and Engineering, 161, 012107. doi: https://doi.org/10.1088/1757-899x/161/1/012107

- Lee, H.-A., Jung, S.-B., Jang, H.-H., Shin, D.-H., Lee, J. U., Kim, K. W., Park, G.-J. (2015). Structural-optimization-based design process for the body of a railway vehicle made from extruded aluminum panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230 (4), 1283–1296. doi: https://doi.org/10.1177/0954409715593971

- Al-Sukhon, A., ElSayed, M. S. (2021). Design optimization of hopper cars employing functionally graded honeycomb sandwich panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 236 (8), 920–935. doi: https://doi.org/10.1177/09544097211049640

- Fomin, O., Gorbunov, M., Gerlici, J., Vatulia, G., Lovska, A., Kravchenko, K. (2021). Research into the Strength of an Open Wagon with Double Sidewalls Filled with Aluminium Foam. Materials, 14 (12), 3420. doi: https://doi.org/10.3390/ma14123420

- Jeong, D. Y., Tyrell, D. C., Carolan, M. E., Perlman, A. B. (2009). Improved Tank Car Design Development: Ongoing Studies on Sandwich Structures. 2009 Joint Rail Conference. doi: https://doi.org/10.1115/jrc2009-63025

- Street, G. E., Mistry, P. J., Johnson, M. S. (2021). Impact Resistance of Fibre Reinforced Composite Railway Freight Tank Wagons. Journal of Composites Science, 5 (6), 152. doi: https://doi.org/10.3390/jcs5060152

- Wróbel, A., Płaczek, M., Buchacz, A. (2017). An Endurance Test of Composite Panels. Solid State Phenomena, 260, 241–248. doi: https://doi.org/10.4028/www.scientific.net/ssp.260.241

- Fomin, O., Gerlici, J., Vatulia, G., Lovska, A., Kravchenko, K. (2021). Determination of the Loading of a Flat Rack Container during Operating Modes. Applied Sciences, 11 (16), 7623. doi: https://doi.org/10.3390/app11167623

- Panchenko, S., Vatulia, G., Lovska, A., Ravlyuk, V., Elyazov, I., Huseynov, I. (2022). Influence of structural solutions of an improved brake cylinder of a freight car of railway transport on its load in operation. EUREKA: Physics and Engineering, 6, 45–55. doi: https://doi.org/10.21303/2461-4262.2022.002638

- Domin, Yu. V., Cherniak, H. Yu. (2003). Osnovy dynamiky vahoniv. Kyiv: KUETT, 269.

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Pavliuchenkov, M., Kravchenko, K. (2022). The Analysis of the Loading and the Strength of the FLAT RACK Removable Module with Viscoelastic Bonds in the Fittings. Applied Sciences, 13 (1), 79. doi: https://doi.org/10.3390/app13010079

- Zadachyn, V. M., Koniushenko, I. H. (2014). Chyselni metody. Kharkiv, 180. Available at: http://kist.ntu.edu.ua/textPhD/CHM_Zadachin.pdf

- Hoi, T. P., Makhnei, O. V. (2012). Dyferentsialni rivniannia. Ivano-Frankivsk, 352. Available at: https://kdrpm.pnu.edu.ua/wp-content/uploads/sites/55/2018/03/deinf_el.pdf

- Siasiev, A. V. (2004). Vstup do systemy MathCad. Dnipropetrovsk, 108. Available at: https://library_donetsk19.donetskedu.com/uk/library/vstup-do-sistemi-mathcad-navchalnii-posibnik.html

- Bohach, I. V., Krakovetskyi, O. Yu., Kylyk, L. V. (2020). Chyselni metody rozviazannia dyferentsialnykh rivnian zasobamy MathCad. Vinnytsia, 106. Available at: http://pdf.lib.vntu.edu.ua/books/IRVC/Bogach_2020_106.pdf

- Koshlan, A., Salnikova, O., Chekhovska, M., Zhyvotovskyi, R., Prokopenko, Y., Hurskyi, T. et al. (2019). Development of an algorithm for complex processing of geospatial data in the special-purpose geoinformation system in conditions of diversity and uncertainty of data. Eastern-European Journal of Enterprise Technologies, 5 (9 (101)), 35–45. doi: https://doi.org/10.15587/1729-4061.2019.180197

- Dudnyk, V., Sinenko, Y., Matsyk, M., Demchenko, Y., Zhyvotovskyi, R., Repilo, I. et al. (2020). Development of a method for training artificial neural networks for intelligent decision support systems. Eastern-European Journal of Enterprise Technologies, 3 (2 (105)), 37–47. doi: https://doi.org/10.15587/1729-4061.2020.203301

- Iwnicki, S. D., Stichel, S., Orlova, A., Hecht, M. (2015). Dynamics of railway freight vehicles. Vehicle System Dynamics, 53 (7), 995–1033. doi: https://doi.org/10.1080/00423114.2015.1037773

- Yang, C., Li, F., Huang, Y., Wang, K., He, B. (2013). Comparative study on wheel–rail dynamic interactions of side-frame cross-bracing bogie and sub-frame radial bogie. Journal of Modern Transportation, 21 (1), 1–8. doi: https://doi.org/10.1007/s40534-013-0001-3

- Bezukhov, N. I. (1957). Sbornik zadach po teorii upru gosti i plastichnosti. Moscow: Gosudartvennoe izdatel'stvo tekhniko-teoreticheskoy literatury, 286.

- Lovska, A. (2014). Assessment of dynamic efforts to bodies of wagons at transportation with railway ferries. Eastern-European Journal of Enterprise Technologies, 3 (4 (69)), 36–41. doi: https://doi.org/10.15587/1729-4061.2014.24997

- Fomin, O., Lovska, A., Khara, M., Nikolaienko, I., Lytvynenko, A., Sova, S. (2022). Adapting the load-bearing structure of a gondola car for transporting high-temperature cargoes. Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 6–13. doi: https://doi.org/10.15587/1729-4061.2022.253770

- Stoilov, V., Simić, G., Purgić, S., Milković, D., Slavchev, S., Radulović, S., Maznichki, V. (2019). Comparative analysis of the results of theoretical and experimental studies of freight wagon Sdggmrss-twin. IOP Conference Series: Materials Science and Engineering, 664 (1), 012026. doi: https://doi.org/10.1088/1757-899x/664/1/012026

- Kondratiev, A. V., Gaidachuk, V. E. (2021). Mathematical Analysis of Technological Parameters for Producing Superfine Prepregs by Flattening Carbon Fibers. Mechanics of Composite Materials, 57 (1), 91–100. doi: https://doi.org/10.1007/s11029-021-09936-3

- Vambol, O., Kondratiev, A., Purhina, S., Shevtsova, M. (2021). Determining the parameters for a 3D-printing process using the fused deposition modeling in order to manufacture an article with the required structural parameters. Eastern-European Journal of Enterprise Technologies, 2 (1 (110)), 70–80. doi: https://doi.org/10.15587/1729-4061.2021.227075

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Alyona Lovska, Volodymyr Nerubatskyi, Andrii Okorokov, Roman Vernyhora, Iryna Zhuravel

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.