Devising a technique and designing an apparatus for obtaining a multifunctional purpose film from intestinal raw materials

DOI:

https://doi.org/10.15587/1729-4061.2023.279008Keywords:

intestinal raw materials, sausage casings, glued intestinal films, beef belly, thermal coagulation, breaking loadAbstract

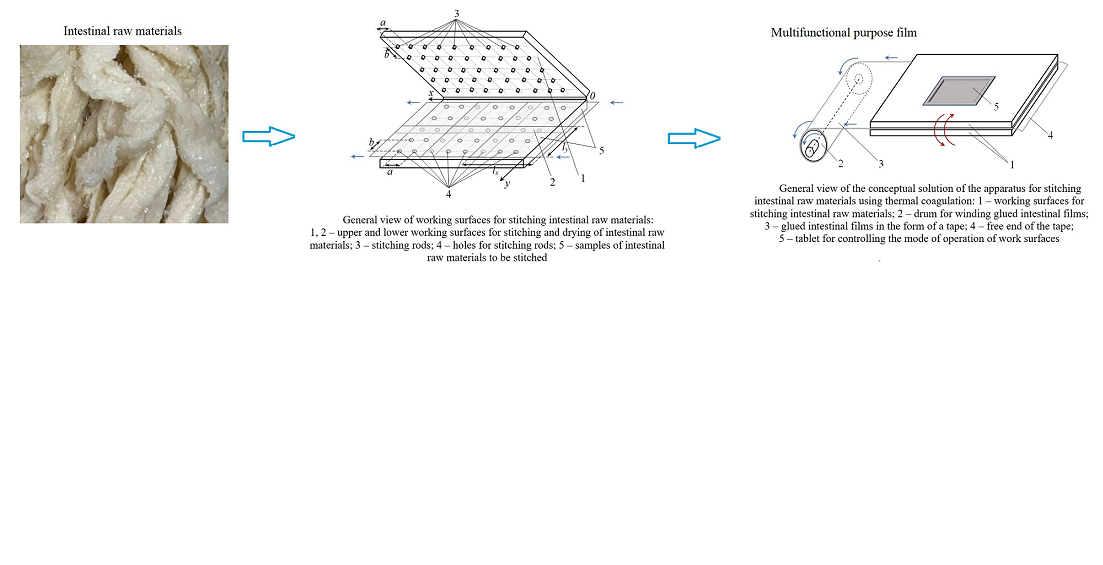

The object of research is a technique for making glued intestinal films for multifunctional purposes, which are further strengthened by a stitching apparatus using thermal coagulation.

This paper substantiates the technical and technological solutions for obtaining glued intestinal films that can be used for the manufacture of sausage casings and as a multifunctional material in the food industry.

The technique and apparatus for stitching intestinal raw materials were developed; the structural features of the apparatus and its rational operation modes were determined. The proposed technique involves stitching by thermal coagulation of intestinal films from beef belly, which belong to intestinal and sausage waste. The possibility of stitching intestinal raw materials, different in size, thickness, and species, is achieved, which allows preserving a valuable animal resource and increasing the efficiency of glued intestinal films technology.

The breaking load of the seam obtained by thermal coagulation was investigated and the rational ranges of stitching duration were determined. The breaking load of the seam was defined, which is a series of points that were subjected to thermal coagulation; its nonlinear change with a change in the distance between points was established. It was found that the values of the breaking load of the seam for the range of distance between the points that create it, from 5 to 20 mm, respectively, lie in the range from 17.5 to 15.0 N/m. This satisfies the technological requirements for the strength of the seam of glued intestinal sausage casings.

The influence of the distance between the points that create a seam between the layers of intestinal raw materials on the outflow of the liquid filling fraction for sausages from the sausage casing was established; the height of the liquid fraction, at which the outflow was considered significant, was determined

References

- Mrugalska, B., Wyrwicka, M. K. (2017). Towards Lean Production in Industry 4.0. Procedia Engineering, 182, 466–473. doi: https://doi.org/10.1016/j.proeng.2017.03.135

- Nicholas, J. (2018). Lean production for competitive advantage: a comprehensive guide to lean methodologies and management practices. Productivity Press. doi: https://doi.org/10.4324/9781351139083

- Kleshchov, A. Y., Khiuhi, K., Khenhevoss, D., Maslikov, M. M. (2018). Resursoefektyvne ta chyste vyrobnytstvo u miasniy promyslovosti. Kyiv: Tsentr resursoefektyvnoho ta chystoho vyrobnytstva, 68. Available at: https://www.researchgate.net/publication/330442289_Resursoefektivne_ta_ciste_virobnictvo_u_m'asnij_promislovosti_Resource_efficient_and_cleaner_production_for_meat_sector/citations

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. doi: https://doi.org/10.15587/1729-4061.2021.240675

- Mykhailov, V. M., Onyshchenko, V. M., Yancheva, M. O., Shubina, L. Yu. (2021). Doslidzhennia zakhysnykh vlastyvostei i bezpechnosti kyshkovykh kovbasnykh obolonok. Kharkiv: KhDUKhT, 107. Available at: https://repo.btu.kharkov.ua/bitstream/123456789/21615/1/Mon_zakhysni%20obolonky_2021.pdf

- Hashim, P., Ridzwan, M., Bakar, J., Hashim, D. (2015). Collagen in food and beverage industries. International Food Research Journal, 22 (1), 1–8. Available at: https://www.researchgate.net/publication/281911258_Collagen_in_food_and_beverage_industries

- Suurs, P., Barbut, S. (2020). Collagen use for co-extruded sausage casings – A review. Trends in Food Science & Technology, 102, 91–101. doi: https://doi.org/10.1016/j.tifs.2020.06.011

- Gómez-Guillén, M. C., Giménez, B., López-Caballero, M. E., Montero, M. P. (2011). Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocolloids, 25 (8), 1813–1827. doi: https://doi.org/10.1016/j.foodhyd.2011.02.007

- Mykhailov, V., Оnishchenko, V. (2016). Theoretical аnd practical prerequisites for the improvement of the technology of glued guts casings. Prohresyvni tekhnika ta tekhnolohiyi kharchovykh vyrobnytstv restorannoho hospodarstva i torhivli, 1 (23), 7–15. Available at: http://elib.hduht.edu.ua/bitstream/123456789/535/1/sec1-t-2016-1-1.pdf

- Savic, Z., Savic, I. (2016). Sausage Casings. Wien: Victus International GmbH, 612. Available at: https://www.linkedin.com/pulse/new-publication-book-sausage-casings-zoran-savic?trk=portfolio_article-card_title

- Bartel, S., Domin, J., Pilch, Z., Karczewski, J. et al. (2020). Joining methods of natural sausage casing with using of high frequency current. 26th International Conference Engineering mechanics 2020. Brno. Available at: https://www.engmech.cz/im/data/doc/Bartel_Sebastian_152_149.pdf

- Bartel, S., Domin, J., Karczewski, J., Kciuk, M., Kozielski, L., Pilch, Z., Wyciślok, P. (2020). Testing the strength of laser-bonded animal intestines. 26th International Conference Engineering mechanics 2020. Brno. Available at: https://www.engmech.cz/im/data/doc/Bartel_Sebastian_166_170.pdf

- Оnishchenko, V., Pak, A., Goralchuk, A., Shubina, L., Bolshakova, V., Inzhyyants, S. et al. (2021). Devising techniques for reinforcing glued sausage casings by using different physical methods. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 6–13. doi: https://doi.org/10.15587/1729-4061.2021.224981

- Mykhailov, V., Оnyshchenko, V., Pak, A., Bredykhin, V., Zahorulko, O. (2021). Investigation of frying process of meat sausages in glued casings from intestinal raw materials. Ukrainian Food Journal, 10 (2), 387–398. doi: https://doi.org/10.24263/2304-974x-2021-10-2-14

- Wijnker, J. J. (2009). Aspects of quality assurance in processing natural sausage casings. Ridderkerk: Ridderprint, 114. Available at: https://www.academia.edu/22843702/Aspects_of_quality_assurance_in_processing_natural_sausage_casings

- Kubit, A., Al-Sabur, R., Gradzik, A., Ochał, K., Slota, J., Korzeniowski, M. (2022). Investigating Residual Stresses in Metal-Plastic Composites Stiffening Ribs Formed Using the Single Point Incremental Forming Method. Materials, 15 (22), 8252. doi: https://doi.org/10.3390/ma15228252

- Fojtl, L., Manas, L., Rusnakova, S. (2018). The Effect of Polymer Pin Ribs on Reinforcement of Sandwich Structures. Manufacturing Technology, 18 (6), 889–894. doi: https://doi.org/10.21062/ujep/196.2018/a/1213-2489/mt/18/6/889

- Barbut, S., Ioi, M., Marcone, M. (2020). Co-extrusion of collagen casings. Effects of preparation, brining, and heating on strength, rheology and microstructure. Italian Journal of Food Science, 32 (1), 91–106. doi: https://doi.org/10.14674/IJFS-1557

- Mykhailov, V. M., Onyshchenko, V. M., Pak, A. O., Inzhyiants, S. T. (2022). Obgruntuvannia tekhnolohiyi skleienykh kyshkovykh kovbasnykh obolonok, armovanykh teplovoiu koahuliatsieiu i dublenniam. Kharkiv: DBTU, 105. Available at: https://repo.btu.kharkov.ua/bitstream/123456789/22535/1/Monohr_OTSKKOATKD_2_2022.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Andrey Pak, Vyacheslav Оnishchenko, Maryna Yancheva, Nataliya Grynchenko, Olena Dromenko, Alina Pak, Samvel Inzhyyants, Аrtem Оnyshchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.