Substantiating the technology of cream-whipped candy masses with the addition of berry and fruit paste

DOI:

https://doi.org/10.15587/1729-4061.2023.279287Keywords:

technology of creamy-whipped candy masses, fruit and berry paste, viscosity, pectin, vitamins, phytosterolsAbstract

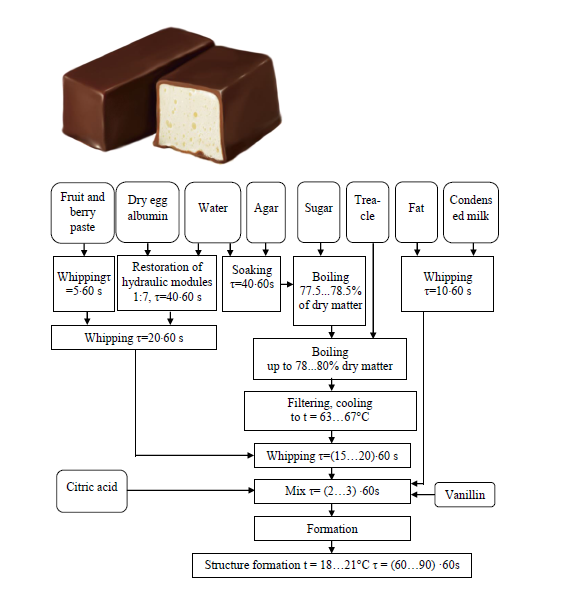

The object of research is the technology of creamy-whipped sweets with the addition of fruit and berry paste. Its addition solves the problem of improving sugar masses, namely structural characteristics and physiological value (enrichment with non-starch polysaccharides, vitamin C, polyphenols, and organic acids). In addition, a positive effect is achieved by providing the products with original organoleptic properties without the use of synthetic dyes and flavors. The proposed fruit and berry paste is obtained at gentle temperatures, which allows preserving the biological potential of raw materials and is characterized by a strong structure with a dynamic viscosity of 498 Pa·s.

It was found that the introduction of fruit and berry paste in the amount of up to 10 % by weight of formulation raw materials improves the foaming ability of protein mass in the process of whipping. Increasing the paste content to 20 % leads to a slight deterioration in this indicator, but its value is at the level of control. The stability of the whipped protein mass increases evenly by increasing the dosage of the additive. The positive effect of fruit and berry paste on the quality indicators of finished creamy-whipped candy masses was noted. Samples with the additive give less shrinkage during the structuring process, its duration is reduced, and strength increases. It is recommended to add fruit and berry paste to creamy-whipped candy masses in the amount of 15 % of the total amount of formulation raw materials and at the same time reduce the formulation dosage of agar by 40 %. Such products acquire an original lilac color, a pleasant yogurt flavor, and the aroma of red currant. The nutrient composition of products is significantly improved – the content of non-starch polysaccharides increases by 2 times; the product is enriched with vitamin C and polyphenolic compounds that are absent in the control sample

References

- Santeramo, F. G., Carlucci, D., De Devitiis, B., Seccia, A., Stasi, A., Viscecchia, R., Nardone, G. (2018). Emerging trends in European food, diets and food industry. Food Research International, 104, 39–47. doi: https://doi.org/10.1016/j.foodres.2017.10.039

- Konar, N., Gunes, R., Palabiyik, I., Toker, O. S. (2022). Health conscious consumers and sugar confectionery: Present aspects and projections. Trends in Food Science & Technology, 123, 57–68. doi: https://doi.org/10.1016/j.tifs.2022.02.001

- Pachón, H. (2023). Food fortification programs. Encyclopedia of Human Nutrition, 288–300. doi: https://doi.org/10.1016/b978-0-12-821848-8.00057-3

- Chadare, F. J., Idohou, R., Nago, E., Affonfere, M., Agossadou, J., Fassinou, T. K. et al. (2019). Conventional and food‐to‐food fortification: An appraisal of past practices and lessons learned. Food Science & Nutrition, 7 (9), 2781–2795. doi: https://doi.org/10.1002/fsn3.1133

- Gunes, R., Palabiyik, I., Konar, N., Said Toker, O. (2022). Soft confectionery products: Quality parameters, interactions with processing and ingredients. Food Chemistry, 385, 132735. doi: https://doi.org/10.1016/j.foodchem.2022.132735

- Samokhvalova, O., Kasabova, K., Oliinyk, S. (2014). The influence of the enriching additives on the dough structure formation and baked muffins. Eastern-European Journal of Enterprise Technologies, 1 (10 (67)), 32–36. doi: https://doi.org/10.15587/1729-4061.2014.20024

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chuiko, L., Yakovets, L., Pugach, A. et al. (2022). Improving the production technology of functional paste-like fruit-and-berry semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 43–52. doi: https://doi.org/10.15587/1729-4061.2022.262924

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. doi: https://doi.org/10.15587/1729-4061.2021.237948

- Zhan, F., Youssef, M., Shah, B. R., Li, J., Li, B. (2022). Overview of foam system: Natural material-based foam, stabilization, characterization, and applications. Food Hydrocolloids, 125, 107435. doi: https://doi.org/10.1016/j.foodhyd.2021.107435

- Tsykhanovska, I., Yevlash, V., Trishch, R., Lazarieva, T., Alexandrov, A., Nikulina, A. (2021). Functional and technological properties of food additive “Magnetofood” in production of shaped jelly marmalade on agar and pectin. Food Science and Technology, 15 (3). doi: https://doi.org/10.15673/fst.v15i3.2119

- Shydakova-Kameniuka, O., Shkliaiev, O., Samokhvalova, O., Artamonova, M., Stepankova, G., Bolkhovitina, O., Rogova, A. (2020). Harnessing the technological potential of chia seeds in the technology of cream-whipped candy masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 52–60. doi: https://doi.org/10.15587/1729-4061.2020.199923

- Ianchyk, M., Niemirich, O., Gavrysh, A. (2016). Study of functional and technological properties of plant powders for use in confectionery industry. Food Science and Technology, 10 (4). doi: https://doi.org/10.15673/fst.v10i4.251

- Romo-Zamarrón, K. F., Pérez-Cabrera, L. E., Tecante, A. (2019). Physicochemical and Sensory Properties of Gummy Candies Enriched with Pineapple and Papaya Peel Powders. Food and Nutrition Sciences, 10 (11), 1300–1312. doi: https://doi.org/10.4236/fns.2019.1011094

- Tipsina, N. N., Prisukhina, N. V. (2009). Pischevye volokna v konditerskom proizvodstve. Vestnik Krasnoyarskogo gosudarstvennogo agrarnogo universiteta, 9, 166–171.

- Dorn, G., Savenkova, T., Sidorova, O., Golub, O. (2015). Confectionery goods for healthy diet. Foods and Raw Materials, 3 (1), 70–76. doi: https://doi.org/10.12737/11240

- Novikova, Z. V., Sergeeva, S. M., Zakharova, A. D., Semisazhonova, J. A. (2019). Justification of the use of green tea “Matcha” in the production of functional confectionery. Proceedings of the Voronezh State University of Engineering Technologies, 81 (1), 168–172. doi: https://doi.org/10.20914/2310-1202-2019-1-168-172

- Shydakova-Kameniuka, E., Novik, A., Zhukov, Y., Matsuk, Y., Zaparenko, A., Babich, P., Oliinyk, S. (2019). Estimation of technological properties of nut meals and their effect on the quality of emulsion for butter biscuits with liquid oils. Eastern-European Journal of Enterprise Technologies, 2 (11 (98)), 56–64. doi: https://doi.org/10.15587/1729-4061.2019.159983

- Dozhdaleva, M. I., Gonchar, V. V., Kalashnova, T. V. (2011). Razrabotka tekhnologiy i retseptur diabeticheskikh sakharistykh konditerskikh izdeliy s ispol'zovaniem produktov pererabotki klubney topinambura. Izvestiya vuzov. Pischevaya tekhnologiya, 2/3, 66–68.

- Pekdogan Goztok, S., Gunes, R., Toker, O. S., Palabiyik, I., Konar, N. (2022). Investigation of the use of various fruit juice concentrates instead of corn syrup in marshmallow type products: A preliminary study. International Journal of Gastronomy and Food Science, 30, 100616. doi: https://doi.org/10.1016/j.ijgfs.2022.100616

- Çoban, B., Bilgin, B., Yurt, B., Kopuk, B., Atik, D. S., Palabiyik, I. (2021). Utilization of the barberry extract in the confectionery products. LWT, 145, 111362. doi: https://doi.org/10.1016/j.lwt.2021.111362

- Deynichenko, G., Lystopad, T., Novik, A., Chernushenko, L., Farisieiev, A., Matsuk, Y., Kolisnychenko, T. (2020). Determining the content of macronutrients in berry sauces using a method of IR-spectroscopy. Eastern-European Journal of Enterprise Technologies, 5 (11 (107)), 32–42. doi: https://doi.org/10.15587/1729-4061.2020.213365

- Kilasoniya, K. G. (2004). Ispol'zovanie pyure feykhoa i kivi dlya polucheniya sbivnykh konditerskikh izdeliy. Pischevaya promyshlennost', 12, 79.

- Khomych, G., Horobets, A., Honcharenko, V., Podonik, Y. (2022). Improvement of technologies of the group of sugar products. Science Bulletin of Poltava University of Economics and Trade, 1, 63–68. doi: https://doi.org/10.37734/2518-7171-2022-1-10

- Prisukhina, N. V., Ermosh, L. G., Tipsina, N. N., Osetrova, P. V. (2020). Razrabotka novogo vida zefira chernosmorodinovogo s ispol'zovaniem bazilika. Bulletin of KSAU, 3, 135–142. doi: https://doi.org/10.36718/1819-4036-2020-3-135-142

- Kasabova, K., Zagorulko, A., Zahorulko, A., Shmatchenko, N., Simakova, O., Goriainova, I. et al. (2021). Improving pastille manufacturing technology using the developed multicomponent fruit and berry paste. Eastern-European Journal of Enterprise Technologies, 3 (11 (111)), 49–56. doi: https://doi.org/10.15587/1729-4061.2021.231730

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. doi: https://doi.org/10.15587/1729-4061.2022.254873

- Samokhvalova, O., Kasabova, K., Shmatchenko, N., Zagorulko, A., Zahorulko, A. (2021). Improving the marmalade technology by adding a multicomponent fruit-and-berry paste. Eastern-European Journal of Enterprise Technologies, 6 (11 (114)), 6–14. doi: https://doi.org/10.15587/1729-4061.2021.245986

- Sadahira, M. S., Rodrigues, M. I., Akhtar, M., Murray, B. S., Netto, F. M. (2018). Influence of pH on foaming and rheological properties of aerated high sugar system with egg white protein and hydroxypropylmethylcellulose. LWT, 89, 350–357. doi: https://doi.org/10.1016/j.lwt.2017.10.058

- Yevlash, V. V., Otroshko, N. O., Vakshul, Z. V. (2012). Kilkisne vyznachennia vitaminu s v modelnykh kharchovykh systemakh. Eastern-European Journal of Enterprise Technologies, 6 (10 (60)), 52–55. Available at: https://core.ac.uk/download/pdf/288833163.pdf

- Ol'khovatov, E. A., Rodionova, L. YA., Scherbakova, E. V. (2010). Pat. No. 2434532 S 1 RF. Sposob opredeleniya massovoy doli pektinovykh veschestv v rastitel'nom syr'e. No. 2010119897/13; declareted: 18.05.2010; published: 27.11.2011.

- DSTU 4373:2005. Frukty, ovochi ta produkty yikh pererobliannia. Metody vyznachannia vmistu polifenoliv.

- Vlizlo, V. V., Fedoruk, R. S., Makar, I. A. et al. (2004). Fizioloho-biokhimichni metody doslidzhen u biolohii, tvarynnytstvi ta veterynarnii medytsyni. Lviv, 400.

- DSTU ISO 6799-2002. Animal and vegetable fast and oils. Determination of composition of the sterol fraction Method using gas chromatography.

- Mehrandish, R., Rahimian, A., Shahriary, A. (2019). Heavy metals detoxification: A review of herbal compounds for chelation therapy in heavy metals toxicity. Journal of Herbmed Pharmacology, 8 (2), 69–77. doi: https://doi.org/10.15171/jhp.2019.12

- Niaz, K., Nawaz, M. A., Pervez, S., Younas, U., Shah, I., Khan, F. (2022), Total scale analysis of organic acids and their role to mitigate Alzheimer's disease. South African Journal of Botany, 144, 437–447. doi: https://doi.org/10.1016/j.sajb.2021.09.020

- Rockenbach, I. I., Rodrigues, E., Gonzaga, L. V., Caliari, V., Genovese, M. I., Gonçalves, A. E. de S. S., Fett, R. (2011). Phenolic compounds content and antioxidant activity in pomace from selected red grapes (Vitis vinifera L. and Vitis labrusca L.) widely produced in Brazil. Food Chemistry, 127 (1), 174–179. doi: https://doi.org/10.1016/j.foodchem.2010.12.137

- Tapiero, H., Townsend, D. M., Tew, K. D. (2003). Phytosterols in the prevention of human pathologies. Biomedicine & Pharmacotherapy, 57 (8), 321–325. doi: https://doi.org/10.1016/s0753-3322(03)00104-5

- Sadahira, M. S., Rodrigues, M. I., Akhtar, M., Murray, B. S., Netto, F. M. (2016). Effect of egg white protein-pectin electrostatic interactions in a high sugar content system on foaming and foam rheological properties. Food Hydrocolloids, 58, 1–10. doi: https://doi.org/10.1016/j.foodhyd.2016.02.007

- Kambulova, Yu., Zvyagintseva-Semenets, Yu., Kobylinskaya, E., Korzun, V., Sokolovskaya, I. (2019). Microstructure of creams made from whipped cream with polysaccharides and various species of sugars. Food Science and Technology, 13 (3). doi: https://doi.org/10.15673/fst.v13i3.1471

- Gohil, R. M. (2010). Synergistic blends of natural polymers, pectin and sodium alginate. Journal of Applied Polymer Science, 120 (4), 2324–2336. doi: https://doi.org/10.1002/app.33422

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Aleksey Zagorulko, Olena Shydakova-Kameniuka, Kateryna Kasabova, Andrii Zahorulko, Nina Budnyk, Iryna Kholobtseva, Liudmyla Kolianovska, Oleksii Shkliaiev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.