Improving the jelly plum juice technology by using secondary products of oil production

DOI:

https://doi.org/10.15587/1729-4061.2023.281929Keywords:

juice yield, juice quality, wheat germ meal, rosehip mealAbstract

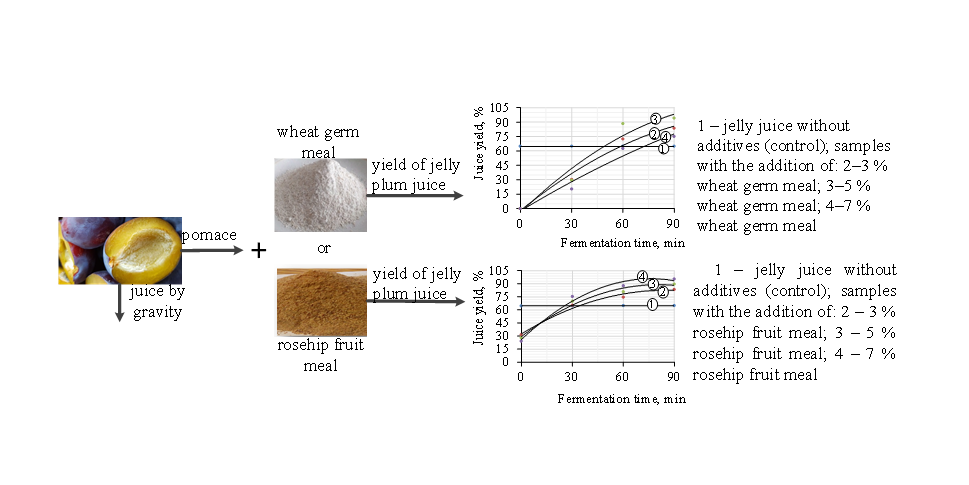

A significant issue related to using pectin-containing raw materials in the production of juices is the reduced yield of the finished product and the formation of a significant amount of waste. It is proposed to consider the possibility of using wheat germ meal and rosehip fruit meal to increase the yield of jelly plum juice by treating with pomace additives. The rich chemical composition of the proposed additives will enrich the juice with essential substances.

It has been experimentally established that in order to increase the yield of jelly plum juice fortified with meal, it is advisable to ferment the pomace for 60 and 90 minutes, followed by pressing. This technological method will make it possible to increase the output of the finished product by adding wheat germ meal, by 11.4–36.1 % and 29.2–45.2 %, respectively; when fortified with rosehip fruit meal, by 15.3–35.0 and 28.8–46.9 %, respectively. In both cases, this occurs due to the hydrolysis of substances in fruit cells: for a first meal – due to its significant enzymatic activity, for a second meal – due to its high acidity.

It has been proven that the high content of nutrients in the meal contributes to the enrichment of jelly plum juice with proteins, non-starch polysaccharides, and vitamin C.

It was established that in order to achieve high product quality, it is advisable to use wheat germ meal in the amount of 5 %, and rosehip fruit meal – 5–7 % in addition to the total weight of plums.

The data reported in this work could be of practical importance at canning industry enterprises. Owing to the proposed technological solutions, manufacturers will be able to increase the profitability of production, reduce the amount of waste that pollutes the environment, and obtain jelly plum juice of enhanced nutritional value with competitive quality indicators

References

- Kaprelyants, L., Yegorova, A., Trufkati, L., Pozhitkova, L. (2019). Functional foods: prospects in Ukraine. Food Science and Technology, 13 (2). doi: https://doi.org/10.15673/fst.v13i2.1382

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chervonyi, V., Omelchenko, O., Sabadash, S. et al. (2018). Universal multifunctional device for heat and mass exchange processes during organic raw material processing. Eastern-European Journal of Enterprise Technologies, 6 (1 (96)), 47–54. doi: https://doi.org/10.15587/1729-4061.2018.148443

- Lapytska, N. V. (2021). Tekhnolohiya napoiv, ekstraktiv ta kontsentrativ. Chernihiv: NUChK imeni T.H. Shevchenka, 217. Available at: http://erpub.chnpu.edu.ua:8080/jspui/handle/123456789/7572

- Matviichuk, N. P. (2017). The market analysis horticultural products of Ukraine. Naukovyi visnyk Uzhhorodskoho natsionalnoho universytetu, 12 (2), 18–23. Available at: http://www.visnyk-econom.uzhnu.uz.ua/archive/12_2_2017ua/6.pdf

- Innovatsiyni napriamy rozvytku kharchovykh tekhnolohiy (2020). Cherkasy: ChDTU, 154. Available at: https://er.chdtu.edu.ua/bitstream/ChSTU/1537/1/%D0%9C%D0%BE%D0%BD%D0%BE%D0%B3%D1%80%D0%B0%D1%84%D1%96%D1%8F%202019.pdf

- Kasabova, E. R., Samokhvalova, O. V. (2013). The influence of food fibers additives on bread-making properties of wheat flour. Nauchnye vedomosti. Estestvennye nauki, 25 (24 (167)), 111–116.

- Oliinyk, S., Samokhvalova, O., Lapitskaya, N., Kucheruk, Z. (2020). Study of the influence of meals of wheat and oat germs and wild rose fruits on the fermenting microflora activity of rye-wheat dough. EUREKA: Life Sciences, 1, 40–47. doi: https://doi.org/10.21303/2504-5695.2020.001114

- Babiy, O. V., Bondarenko, Y. V., Ivchenko, D. S. (2018). Analysis and prospects for the development of juices and juice products market. Herald of Lviv University of Trade and Economics, 20, 57–62. Available at: http://journals-lute.lviv.ua/index.php/visnyk-tech/article/view/297/

- Khomych, G., Polozhyshnikova, L. (2015). The change in the content of biologically active substances of black elderberry in the production of juice. Eastern-European Journal of Enterprise Technologies, 5 (11 (77)), 62–67. doi: https://doi.org/10.15587/1729-4061.2015.51064

- Saleba, L. V., Saribekova, D. G., Zhebrakovskaya, I. A. (2020). Determination of quality indicators and methods of their control for orange juice drinks. Visnyk Khersonskoho natsionalnoho tekhnichnoho universytetu, 2 (73), 54–60. doi: https://doi.org/10.35546/kntu2078-4481.2020.2.6

- Arpul, O., Usatiuk, O., Zhukova, N. (2015). The use of plant material for enrichment of fresh juices by biologically active substances. Technology Audit and Production Reserves, 3 (3 (23)), 22–25. https://doi.org/10.15587/2312-8372.2015.44052

- Lachowicz, S., Oszmiański, J. (2018). The influence of addition of cranberrybush juice to pear juice on chemical composition and antioxidant properties. Journal of Food Science and Technology, 55 (9), 3399–3407. doi: https://doi.org/10.1007/s13197-018-3233-8

- Reddy, M. R., Aruna, R., Sri Latha, V., Prabhakar, B. (2022). Physico Chemical Parameters of Muskmelon Juice Enriched with Probiotic Lactic Acid Bacteria. Journal of Pure and Applied Microbiology, 16 (4), 2439–2450. doi: https://doi.org/10.22207/jpam.16.4.04

- Souza, M., Mesquita, A., Souza, P., Borges, G., Silva, T., Converti, A., Maciel, M. I. (2021). New functional non-dairy mixed tropical fruit juice microencapsulated by spray drying: Physicochemical characterization, bioaccessibility, genetic identification and stability. LWT, 152, 112271. doi: https://doi.org/10.1016/j.lwt.2021.112271

- Ueda, J. M., Pedrosa, M. C., Heleno, S. A., Carocho, M., Ferreira, I. C. F. R., Barros, L. (2022). Food Additives from Fruit and Vegetable By-Products and Bio-Residues: A Comprehensive Review Focused on Sustainability. Sustainability, 14 (9), 5212. doi: https://doi.org/10.3390/su14095212

- Chen, X., Xu, Y., Wu, J., Yu, Y., Zou, B., Li, L. (2023). Effects of Pectinase Pre-Treatment on the Physicochemical Properties, Bioactive Compounds, and Volatile Components of Juices from Different Cultivars of Guava. Foods, 12 (2), 330. doi: https://doi.org/10.3390/foods12020330

- Haile, S., Masi, C., Tafesse, M. (2022). Isolation and characterization of pectinase-producing bacteria (Serratia marcescens) from avocado peel waste for juice clarification. BMC Microbiology, 22 (1). doi: https://doi.org/10.1186/s12866-022-02536-8

- Shydakova-Kameniuka, E., Novik, A., Zhukov, Y., Matsuk, Y., Zaparenko, A., Babich, P., Oliinyk, S. (2019). Estimation of technological properties of nut meals and their effect on the quality of emulsion for butter biscuits with liquid oils. Eastern-European Journal of Enterprise Technologies, 2 (11 (98)), 56–64. doi: https://doi.org/10.15587/1729-4061.2019.159983

- Ermakov, A. I., Arasimovich, V. V., Yaroshi, N. P. et al. (1987). Metody biokhimicheskogo issledovaniya rasteniy. Leningrad: Agropromizdat, 430.

- Panosyan, I. I., Abramova, E. N., Kiseleva, T. A. et al. (1990). Fermentativnyy metod opredeleniya pischevykh volokon v produktakh. Voprosy pitaniya, 5, 54–56.

- Drobot, V. I., Yurchak, V. H., Bilyk, O. A., Bondarenko, Yu. V. et al. (2015). Tekhnokhimichnyi kontrol syrovyny ta khlibobulochnykh i makaronnykh vyrobiv. Kyiv, 972.

- Pohozhykh, M. I., Vorontsova, Zh. V. (2011). Vyznachennia dyspersnykh kharakterystyk kharchovykh poroshkiv mikroskopichnym metodom. Novitni tendentsiyi u kharchovykh tekhnolohiyakh ta yakist i bezpechnist produktiv: zb. statei III Vseukr. nauk.-prakt. konf. Lviv, 88–92.

- Horalchuk, A. B., Pyvovarov, P. P., Hrynchenko, O. O. et al. (2006). Reolohichni metody doslidzhennia syrovyny i kharchovykh produktiv ta avtomatyzatsiya rozrakhunkiv reolohichnykh kharakterystyk. Kharkiv, 73.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nadiia Lapytska, Olga Syza, Olena Gorodyska, Olesya Savchenko, Euvgene Rebenok

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.