Valorization of cashew nut processing by-product: development of a cardol/starch biopolymer composite with electrochemical properties and technological potential

DOI:

https://doi.org/10.15587/1729-4061.2023.282208Keywords:

cardol, cassava, biopolymer, electrochemistry, composite, waste, cashew, nut, shell, starchAbstract

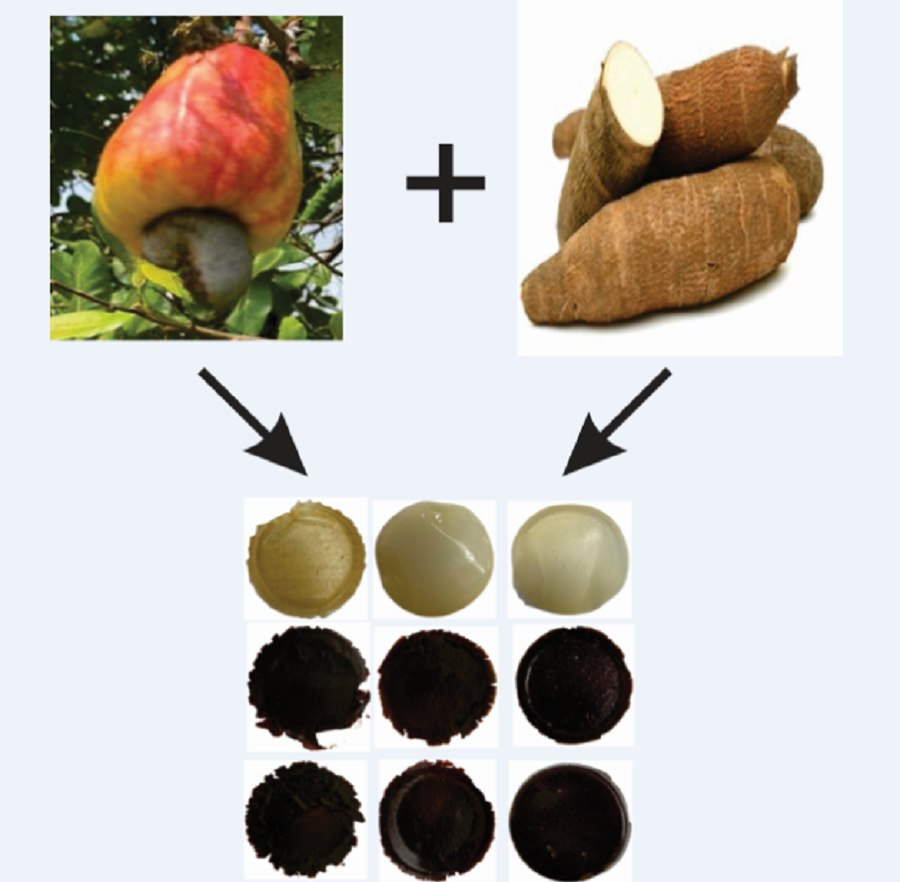

The problem of food agro-industry residues represents a growing concern in our society, therefore its use as a raw material to obtain biopolymers of technological interest is an attractive alternative. The objective of this work was to assess the viability of utilizing cardol, derived from cashew nut shell liquid, in the production of a biopolymer composite by combining it with cassava starch. The biopolymer composite was prepared by thermochemical method using different cardol concentrations and varying the synthesis pH. The results allowed us to demonstrate the formation of cardol/starch biopolymeric films. The infrared spectra showed possible interactions by hydrogen bonds between the cardol and the glucose units of the starch. The impedance behavior showed a similar conduction mechanism in all cases, allowing the establishment of a single equivalent circuit. The electrochemical parameters showed that the presence of cardol and the lower pH increased the values of the electrical resistance and the double layer capacitance in the biopolymers. In addition, the values of the CPE/Rre system, related to the electractivity, were not affected by the pH, but by the presence of cardol. The biodegradability tests showed a complete decomposition of the biopolymer composite films in three stages in a period of 17 to 19 days. It could be concluded that it is possible to use the cardol extracted from the cashew nut shell liquid to elaborate a biopolymer composite with electrochemical properties when combined with cassava starch. The electrical properties of the biopolymer can be modulated by varying the synthesis pH and the amount of cardol used. The composite cardol/starch biopolymer could be used as a biopolymeric solid electrolyte in the manufacture of batteries, capacitors, etc

Supporting Agency

- Acknowledgment to Minciencias (Ministry of Science, Technology, and Innovation) for financing the project identified with BPIN 2020000100027 with resources from the SGR - General Royalties System. The collaboration of the association of cashew producers of the savannah (ASOPROMARSAB) is also appreciated for the supply of cashew nut shells.

References

- Arya, P. S., Yagnik, S. M., Rajput, K. N., Panchal, R. R., Raval, V. H. (2022). Valorization of agro-food wastes: Ease of concomitant-enzymes production with application in food and biofuel industries. Bioresource Technology, 361, 127738. doi: https://doi.org/10.1016/j.biortech.2022.127738

- Freitas, L. C., Barbosa, J. R., da Costa, A. L. C., Bezerra, F. W. F., Pinto, R. H. H., Carvalho Junior, R. N. de. (2021). From waste to sustainable industry: How can agro-industrial wastes help in the development of new products? Resources, Conservation and Recycling, 169, 105466. doi: https://doi.org/10.1016/j.resconrec.2021.105466

- Topare, N. S., Bokil, S. A. (2021). Adsorption of textile industry effluent in a fixed bed column using activated carbon prepared from agro-waste materials. Materials Today: Proceedings, 43, 530–534. doi: https://doi.org/10.1016/j.matpr.2020.12.029

- Asiri, F., Chu, K.-H. (2022). Valorization of agro-industrial wastes into polyhydroxyalkanoates-rich single-cell proteins to enable a circular waste-to-feed economy. Chemosphere, 309, 136660. doi: https://doi.org/10.1016/j.chemosphere.2022.136660

- Paula, R. S. F., Vieira, R. S., Luna, F. M. T., Cavalcante, C. L., Figueredo, I. M., Candido, J. R. et al. (2020). A potential bio-antioxidant for mineral oil from cashew nutshell liquid: an experimental and theoretical approach. Brazilian Journal of Chemical Engineering, 37 (2), 369–381. doi: https://doi.org/10.1007/s43153-020-00031-z

- Adekanbi, M. L., Olugasa, T. T. (2022). Utilizing cashew nut shell liquid for the sustainable production of biodiesel: A comprehensive review. Cleaner Chemical Engineering, 4, 100085. doi: https://doi.org/10.1016/j.clce.2022.100085

- Araujo, J. T. C. de, Martin-Pastor, M., Pérez, L., Pinazo, A., Sousa, F. F. O. de. (2021). Development of anacardic acid-loaded zein nanoparticles: Physical chemical characterization, stability and antimicrobial improvement. Journal of Molecular Liquids, 332, 115808. doi: https://doi.org/10.1016/j.molliq.2021.115808

- Yang, Y., Zhang, C., Han, Y., Weng, Y. (2022). Plasticizing and thermal stabilizing effect of bio‐based epoxidized cardanol esters on PVC. Polymers for Advanced Technologies, 34 (1), 181–194. doi: https://doi.org/10.1002/pat.5876

- Masood, S., Khan, S., Ghosal, A., Alam, M., Rana, D., Zafar, F., Nishat, N. (2023). Fabrication of cardanol (a phenolic lipid) based polyamine coatings for anti-corrosive applications. Progress in Organic Coatings, 174, 107304. doi: https://doi.org/10.1016/j.porgcoat.2022.107304

- De Andrade, J. R., Oliveira, S. N., Soares, J. B., Soares, S. A. (2017). The effect of cardanol-formaldehyde resin in the rheological properties of the asphalt binder. International Journal of Civil & Environmental Engineering, 17 (2), 1–10. Available at: https://repositorio.ufc.br/handle/riufc/37355

- Preethi, R., Moses, J. A., Anandharamakrishnan, C. (2021). Development of anacardic acid incorporated biopolymeric film for active packaging applications. Food Packaging and Shelf Life, 28, 100656. doi: https://doi.org/10.1016/j.fpsl.2021.100656

- Liu, Z., Chen, J., Knothe, G., Nie, X., Jiang, J. (2016). Synthesis of Epoxidized Cardanol and Its Antioxidative Properties for Vegetable Oils and Biodiesel. ACS Sustainable Chemistry & Engineering, 4 (3), 901–906. doi: https://doi.org/10.1021/acssuschemeng.5b00991

- Makwana, K., Ichake, A. B., Valodkar, V., Padmanaban, G., Badiger, M. V., Wadgaonkar, P. P. (2022). Cardol: Cashew nut shell liquid (CNSL) - derived starting material for the preparation of partially bio-based epoxy resins. European Polymer Journal, 166, 111029. doi: https://doi.org/10.1016/j.eurpolymj.2022.111029

- Yuliana, M., Nguyen-Thi, B. T., Faika, S., Huynh, L. H., Soetaredjo, F. E., Ju, Y.-H. (2014). Separation and purification of cardol, cardanol and anacardic acid from cashew (Anacardium occidentale L.) nut-shell liquid using a simple two-step column chromatography. Journal of the Taiwan Institute of Chemical Engineers, 45 (5), 2187–2193. doi: https://doi.org/10.1016/j.jtice.2014.07.012

- Lv, J., Liu, Z., Zhang, J., Huo, J., Yu, Y. (2017). Bio-based episulfide composed of cardanol/cardol for anti-corrosion coating applications. Polymer, 121, 286–296. doi: https://doi.org/10.1016/j.polymer.2017.06.036

- Paiva Filho, J. C., Morais, S. M. de, Nogueira Sobrinho, A. C., Cavalcante, G. S., Silva, N. A. da, Abreu, F. O. M. da S. (2019). Design of chitosan-alginate core-shell nanoparticules loaded with anacardic acid and cardol for drug delivery. Polímeros, 29 (4). doi: https://doi.org/10.1590/0104-1428.08118

- Xie, J., Hong, Y., Gu, Z., Cheng, L., Li, Z., Li, C., Ban, X. (2023). Highland Barley Starch: Structures, Properties, and Applications. Foods, 12 (2), 387. doi: https://doi.org/10.3390/foods12020387

- Tafa, K. D., Satheesh, N., Abera, W. (2023). Mechanical properties of tef starch based edible films: Development and process optimization. Heliyon, 9 (2), e13160. doi: https://doi.org/10.1016/j.heliyon.2023.e13160

- Núñez D, Y. E., Arrieta A, Á. A., Segura B, J. A., Bertel H, S. D. (2016). Synthesis of an air-working trilayer artificial muscle using a conductive cassava starch biofilm (manihot esculenta, cranz) and polypyrrole (PPy). Journal of Physics: Conference Series, 687, 012042. doi: https://doi.org/10.1088/1742-6596/687/1/012042

- Thieme, M., Hochmuth, A., Ilse, T. E., Cuesta-Seijo, J. A., Stoma, S., Meier, R. et al. (2023). Detecting variation in starch granule size and morphology by high-throughput microscopy and flow cytometry. Carbohydrate Polymers, 299, 120169. doi: https://doi.org/10.1016/j.carbpol.2022.120169

- Bangar, S. P., Scott Whiteside, W., Suri, S., Barua, S., Phimolsiripol, Y. (2022). Native and modified biodegradable starch‐based packaging for shelf‐life extension and safety of fruits/vegetables. International Journal of Food Science & Technology, 58 (2), 862–870. doi: https://doi.org/10.1111/ijfs.16219

- Guru, P. R., Kar, R. K., Nayak, A. K., Mohapatra, S. (2023). A comprehensive review on pharmaceutical uses of plant-derived biopolysaccharides. International Journal of Biological Macromolecules, 233, 123454. doi: https://doi.org/10.1016/j.ijbiomac.2023.123454

- Liu, X., Guo, Q., Ren, S., Guo, J., Wei, C., Chang, J., Shen, B. (2022). Synthesis of starch‐based flocculant by multi‐component grafting copolymerization and its application in oily wastewater treatment. Journal of Applied Polymer Science, 140 (4). doi: https://doi.org/10.1002/app.53356

- Arrieta, A. A., Gañán, P. F., Márquez, S. E., Zuluaga, R. (2011). Electrically conductive bioplastics from cassava starch. Journal of the Brazilian Chemical Society, 22 (6), 1170–1176. doi: https://doi.org/10.1590/s0103-50532011000600024

- Anjum, M. M., Patel, K. K., Pandey, N., Tilak, R., Agrawal, A. K., Singh, S. (2019). Development of Anacardic Acid/hydroxypropyl-β-cyclodextrin inclusion complex with enhanced solubility and antimicrobial activity. Journal of Molecular Liquids, 296, 112085. doi: https://doi.org/10.1016/j.molliq.2019.112085

- Oliveira, S., Uchoa, A., Moreira, D., Petzhold, C., Weiss, C., Landfester, K., Ricardo, N. (2023). Design and Evaluation of Dual Release from Anacardic Acid-Based Polyurea Nanocapsules Components. Journal of the Brazilian Chemical Society. doi: https://doi.org/10.21577/0103-5053.20220129

- Almario, A. A., Mogollón, C. G., Caballero, E. C. (2019). Effect of elaboration pH on the electroactivity of cassava starch solid biopolymer electrolyte films. Rasayan Journal of Chemistry, 12 (04), 1766–1773. doi: https://doi.org/10.31788/rjc.2019.1245302

- Udhayasankar, R., Karthikeyan, B., Balaji, A. (2018). Coconut shell particles reinforced cardanol–formaldehyde resole resin biocomposites: Effect of treatment on thermal properties. International Journal of Polymer Analysis and Characterization, 23 (3), 252–259. doi: https://doi.org/10.1080/1023666x.2018.1427187

- Thiyagu, T. T., J.V, S. P. K., P, G., Sathiyamoorthy, V., T, M., VR, A. P. (2021). Effect of cashew shell biomass synthesized cardanol oil green compatibilizer on flexibility, barrier, thermal, and wettability of PLA/PBAT biocomposite films. Biomass Conversion and Biorefinery. doi: https://doi.org/10.1007/s13399-021-01941-9

- Arrieta, A. A., Nuñez de la Rosa, Y., Palencia, M. (2023). Electrochemistry Study of Bio-Based Composite Biopolymer Electrolyte—Starch/Cardol. Polymers, 15 (9), 1994. doi: https://doi.org/10.3390/polym15091994

- Phani Kumar, P., Paramashivappa, R., Vithayathil, P. J., Subba Rao, P. V., Srinivasa Rao, A. (2002). Process for Isolation of Cardanol from Technical Cashew (Anacardium occidentale L.) Nut Shell Liquid. Journal of Agricultural and Food Chemistry, 50 (16), 4705–4708. doi: https://doi.org/10.1021/jf020224w

- Shukur, M. F., Ithnin, R., Kadir, M. F. Z. (2013). Electrical properties of proton conducting solid biopolymer electrolytes based on starch–chitosan blend. Ionics, 20 (7), 977–999. doi: https://doi.org/10.1007/s11581-013-1033-8

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Alvaro Angel Arrieta, Jorge Alberto Ducuara, Enrique Miguel Combatt

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.