Optimization of technological parameters in the production of cereal beverages fortified with Omega-3 polyunsaturated fatty acids

DOI:

https://doi.org/10.15587/1729-4061.2023.282694Keywords:

cereal drink, Omega-3, fortification, functional drink, amino acid score, fatty acid composition, optimization of technological parametersAbstract

The object of this study was cereal drinks fortified with Omega-3 polyunsaturated fatty acids: rice (product 1), oat (product 2), buckwheat (product 3). The purpose of the research was to optimize technological parameters in the production of such beverages.

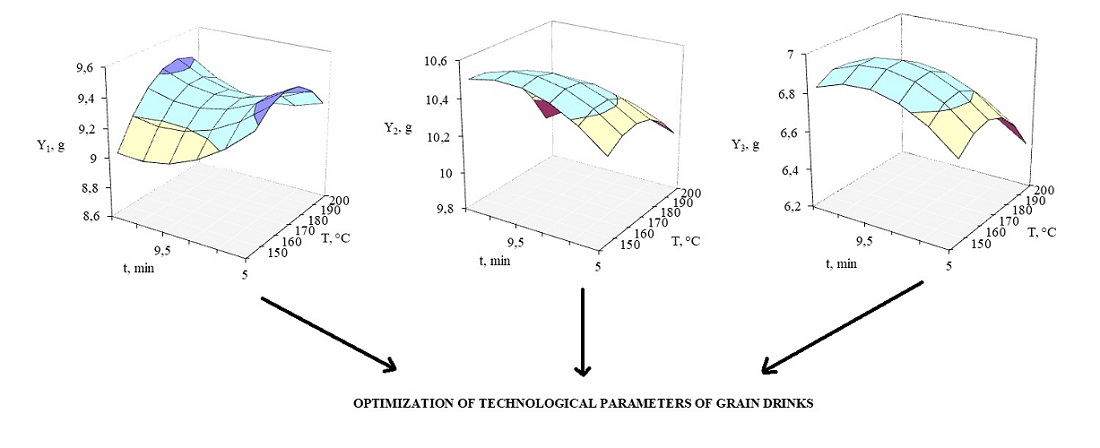

A mathematical model was built in the form of three regression equations describing the influence of grinding size (K), roasting temperature (Т), and roasting duration (t) on three output variables: oat, buckwheat, and rice protein content. Statistical analysis of the obtained equations showed that they are adequate in the selected area of planning: K=0.66–2.34 mm, T=133–217 °С, t=3.3–11.7 min.

Studies were conducted to determine quality indicators, chemical composition, biological and nutritional value of the developed cereal drinks, in comparison with the control version.

It has been established that the content of fatty acid composition of cereal drinks differs markedly. The minimum share of saturated fatty acids was established in product No. 3, without fortification – 10.43 %. The content of polyunsaturated fatty acids ranged from 82.09 % (product 1) to 89.57 % (product 3). The highest omega-3 content was found in product 2, with fortification – 1.34 %, and the lowest – in product 1, without fortification – 0.27 %.

The introduction of a filler in cereal drinks made it possible to add protein, thereby increasing the biological value. According to the content of essential amino acids, the devised product is characterized by a high content of essential amino acids, exceeding the FAO/WHO ideal protein scale, which allows us to draw a conclusion about the high biological value of the developed product.

The analysis of the mathematical model built established that an increase in the coarseness of grinding leads to a decrease in the protein content in the entire investigated range of values of this factor

References

- Gurskikh, P. S., Yanova, M. A. (2017). Issledovanie muki iz ekstrudata zerna ovsa dlya proizvodstva zernovogo napitka. Khlebobulochnye, konditerskie i makaronnye izdeliya XXI veka: mat-ly V Mezhdunar. nauch.-prakt. konf., 107–108.

- Mayurnikova, L., Koksharov, A., Krapiva, T., Novoselov, S. (2020). Food Fortification as a Preventive Factor of Micronutrient Deficiency. Food Processing: Techniques and Technology, 50 (1), 124–139. doi: https://doi.org/10.21603/2074-9414-2020-1-124-139

- Obzor rossiyskogo rynka krup. Available at: http://www.marketcenter.ru/content/doc-2-8822.html

- Khastayeva, A., Bekturganova, A., Omaraliyeva, A., Safuani, Z., Baykhozhayeva, B., Botbayeva, Z. (2022). Justification of the selection of cereal crops for the production of new cereal beverages. Eastern-European Journal of Enterprise Technologies, 5 (11 (119)), 55–65. doi: https://doi.org/10.15587/1729-4061.2022.265811

- Pat. No. 2333656 RU. Sposob prigotovleniya rastitel'nogo moloka iz semyan l'na. Available at: https://findpatent.ru/patent/233/2333656.html

- Pat. No. 2454084 RU. Soderzhaschie suspendirovannye chastitsy podkislennye belkovye napitki i sposoby ikh prigotovleniya. Available at: https://findpatent.ru/patent/245/2454084.html

- Pat. No. 2616802 RU. Zhidkaya ovsyanaya osnova. Available at: https://findpatent.ru/patent/261/2616802.html

- Pat. No. 2756071 RU. Sposob polucheniya rastitel'nogo moloka. Available at: https://findpatent.ru/patent/275/2756071.html

- Pat. No. 2185069 RU. Sposob polucheniya rastitel'nogo moloka iz semyan konopli. Available at: https://findpatent.ru/patent/218/2185069.html

- Skorkina, S. S. (2015). Geneticheskiy analiz priznaka «Chislo zeren v glavnoy metelke» na osnove diallel'nykh skreschivaniy. Risovodstvo, 1-2 (26-27), 24.

- Delgado-Andrade, C., Navarro, M., López, H., López, M. C. (2003). Determination of total arsenic levels by hydride generation atomic absorption spectrometry in foods from south-east Spain: estimation of daily dietary intake. Food Additives and Contaminants, 20 (10), 923–932. doi: https://doi.org/10.1080/02652030310001594450

- Nurgalieva, M. T., Toyshimanov, M. R., Serikov, M. S., Myrzabaeva, N. E., Khastaeva, A. Zh. (2019). Kalibrovka gazokhromatograficheskogo pribora dlya opredeleniya zhirnokislotnogo sostava pischevykh produktov. Іzdenіster, nәtizheler. Issledovaniya, rezul'taty, 1, 79–85.

- Strelets, V. D., Krol', T. A. (2010). Produktvnost' sortov i zhirnokislotnyy sostav masla semyan l'na maslichnogo, vyraschennogo v usloviyakh Moskovskoy oblasti. Izvestiya TSKhA, 1, 121–132.

- Nechaev, A. P. et al. (2015). Pischevaya khimiya. Sankt-Peterburg: GIORD, 672.

- Musina, O. N., Schetinin, M. P. (2010). Polikomponentnye produkty na osnove kombinirovaniya molochnogo i zernovogo syr'ya. Barnaul: Izd-vo Alt. un-ta, 97.

- Lotochnikova, T. N. (2006). Izmenchivost' tekhnologicheskikh i biokhimicheskikh priznakov kachestva zerna novykh sortov risa rossiyskoy selektsii. Krasnodar.

- Domina, O. (2020). Selection of alternative solutions in the optimization problem of network diagrams of project implementation. Technology Audit and Production Reserves, 4 (4 (54)), 9–22. doi: https://doi.org/10.15587/2706-5448.2020.210848

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Aigerim Khastayeva, Almira Bekturganova, Aigul Omaraliyeva, Almas Serikov, Aidana Myrzhykbayeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.