Design of the human-machine interface for the cleaning-in-place system in the dairy industry

DOI:

https://doi.org/10.15587/1729-4061.2023.282695Keywords:

human-machine interface, dairy industry, systems, cleaning in place, WinCC FlexibleAbstract

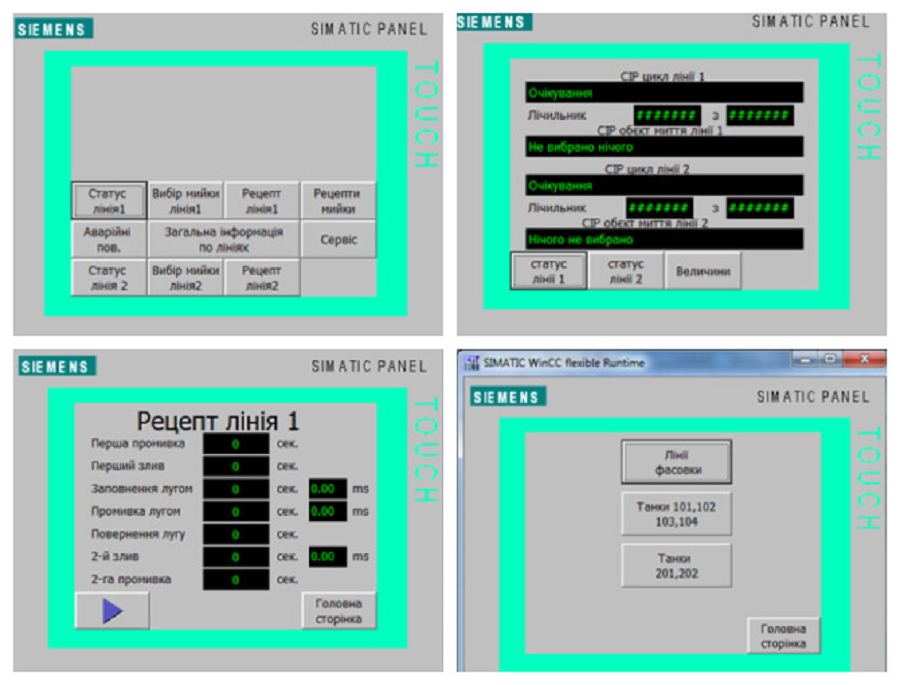

The dairy industry must focus on sanitation and hygiene requirements to ensure product safety, control of detergents, tanks, pumps. Compliance with these requirements will provide conditions for the production of a high-quality dairy product, maintenance of technical and mechanical frequency at the enterprise, and prevention of the reproduction of harmful bacteria. Under these conditions, the problem of cleaning technical equipment from harmful residues on site is urgent. The object of the study is the basic processes in the Cleaning-In-Place system in the dairy industry. It is recommended to design a human-machine interface for on-site cleaning in the Siemens WinCC Flexible software. It is worth noting that the proposed interface takes into account the reduction of equipment downtime during the washing of technological equipment, a convenient user interface, and ease of maintenance. The state of use of existing visualizations of on-site cleaning interfaces that do not use simultaneous washing of two tanks with cleaning solutions (alkaline and acid) and the state of controlled values in selected washing lines were evaluated. Numerical evaluations of the results use modern programming technology and high information productivity of the user interface. A human-machine interface was designed with the possibility of parallel cleaning of two tanks at different ends of the workshop and the selection of recipes for different groups of tanks. This interface displays emergency messages, the status of the washing process of production lines and control based on data from sensors. The practical use of the obtained scientific results is that the designed interface can be used not only in the dairy industry but in any other food industry

References

- Belei, O. I., Huchok, A., Kritsak, A. (2017). Teoretychni peredumovy stvorennia avtomatyzovanoi systemy CIP myiky. Suchasni informatsiyni tekhnolohiyi v dystantsiyniy osviti: V Vseukrainskyi naukovo-praktychnyi seminar (SITvDO-2017). Ivano-Frankivsk: IFNTUNH, 43–45. Available at: http://elar.nung.edu.ua/bitstream/123456789/8224/1/7867p.pdf

- CIP-myika. Aktsionerne tovarystvo «ATTIS». Available at: http://www.attis.com.ua/site/equipment/CIP.html

- Stantsiyi CIP-myiky. Available at: https://kmbp.com.ua/produktsiya/rishennia-dlia-molochnoi-promyslovosti/stantsiji-cip-mijki

- Mini myika CIP. Lakta-Service. Available at: https://lakta-service.com/product/mini-mijka-cip/

- CIP-myika. EKOKOM. Available at: https://www.ekokom.com/services/cip-mojka

- Xihuaxi, S. (2016). Pat. No. CN106387047A. CIP (Clean in Place) cleaning method for dairy production line. No. CN201610796871.8A; declareted: 31.08.2016; published: 15.02.2017. Available at: https://patents.google.com/patent/CN106387047A/en

- Single versus Multiuse CIP Designs. Available at: https://www.sciencedirect.com/topics/food-science/clean-in-place

- Silva, L. D., Aguiar, M. M., Paiva, A. D., Bernardes, P. C., Gedraite, R., Naves, E. A. A. (2023). Optimization of clean-in-place (CIP) procedure of pipelines contaminated with Bacillus cereus by applying pulsed flow. Food Control, 147, 109565. doi: https://doi.org/10.1016/j.foodcont.2022.109565

- Davey, K. R., Chandrakash, S., O’Neill, B. K. (2013). A new risk analysis of Clean-In-Place milk processing. Food Control, 29 (1), 248–253. doi: https://doi.org/10.1016/j.foodcont.2012.06.014

- Dev, S. R. S., Demirci, A., Graves, R. E., Puri, V. M. (2014). Optimization and modeling of an electrolyzed oxidizing water based Clean-In-Place technique for farm milking systems using a pilot-scale milking system. Journal of Food Engineering, 135, 1–10. doi: https://doi.org/10.1016/j.jfoodeng.2014.02.019

- Thomas, A., Sathian, C. T. (2014). Cleaning-In-Place (CIP) System in Dairy Plant- Review. IOSR Journal of Environmental Science, Toxicology and Food Technology, 8 (6), 41–44. doi: https://doi.org/10.9790/2402-08634144

- How is the user interface language set in WinCC flexible? Siemens. Available at: https://support.industry.siemens.com/cs/document/18922331/how-is-the-user-interface-language-set-in-wincc-flexible-?dti=0&lc=en-UA

- Zubkov, O. V. (2011). Prohramuvannia promyslovykh kontroleriv Siemens v prykladakh i zadachakh. Kharkiv, 122. Available at: https://openarchive.nure.ua/server/api/core/bitstreams/04d63150-37b3-4771-a4fd-f0a3a86acd16/content

- Jones, C. (2009). STEP 7 in 7 Steps: A Practical Guide to Implementing S7-300/S7-400 Programmable Logic Controllers. Brilliant Training, 464. Available at: https://www.etf.ues.rs.ba/~slubura/Procesni%20racunari/step7in7step/Step7in7step.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oksana Belei, Lidiia Shtaier, Roman Stasіuk, Aleksandra Mirzojeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.