Increasing the oxidative stability of linseed oil

DOI:

https://doi.org/10.15587/1729-4061.2023.284314Keywords:

linseed oil, free-radical process, oxidative stability, induction period, oxidation inhibitorAbstract

The object of the research is the process of oxidation of linseed oil at elevated temperature.

Linseed oil is a valuable raw material for the chemical, food, cosmetic and other industries. The use of linseed oil is complicated by intensive oxidation processes associated with a high content of unsaturated fatty acids. Therefore, an important task is to develop and improve methods of oxidative stabilization of linseed oil.

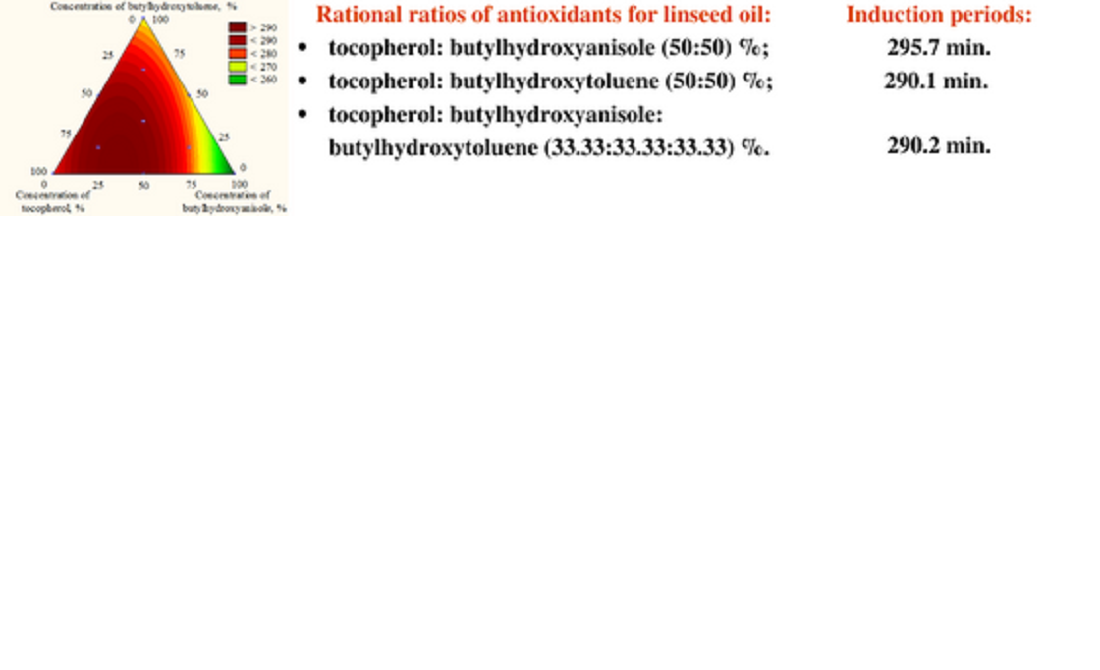

The oxidation process of unrefined linseed oil (CAS Number 8001-26-1) at a temperature of 110 °C in its original form and with the addition of antioxidants was studied. The effect of antioxidant concentrations (tocopherol, butylhydroxyanisole and butylhydroxytoluene) in the mixture on the induction period of linseed oil was found. The induction period was determined by differential scanning calorimetry. The total concentration of the mixture of antioxidants in each experiment was 0.02 %. The induction period of the initial oil was 155.31 min. Rational ratios of antioxidants in the mixture were found: tocopherol: butylhydroxyanisole (50:50) %; tocopherol: butylhydroxytoluene (50:50) %; tocopherol: butylhydroxyanisole: butylhydroxytoluene (33.33:33.33:33.33) %. At the same time, the oil induction periods are 295.7 min., 290.1 min. and 290.2 min., respectively.

The quality indicators of the initial linseed oil and with the addition of the determined rational ratios of antioxidants after 2 hours of aging at a temperature of 110 °C were determined. The peroxide values of the samples were 8.5, 3.2, 3.6, 3.7 ½ O mmol/kg, respectively.

The research results make it possible to introduce antioxidants in the production of linseed oil in rational concentrations. This will help increase the production of linseed oil resistant to oxidation at elevated temperatures, which will provide various industries with high-quality raw materials

References

- Juita, Dlugogorski, B. Z., Kennedy, E. M., Mackie, J. C. (2013). Roles of peroxides and unsaturation in spontaneous heating of linseed oil. Fire Safety Journal, 61, 108–115. doi: https://doi.org/10.1016/j.firesaf.2013.07.005

- Chernukha, A., Teslenko, A., Kovalov, P., Bezuglov, O. (2020). Mathematical Modeling of Fire-Proof Efficiency of Coatings Based on Silicate Composition. Materials Science Forum, 1006, 70–75. doi: https://doi.org/10.4028/www.scientific.net/msf.1006.70

- Slyusar, V., Protsenko, M., Chernukha, A., Melkin, V., Biloborodov, O., Samoilenko, M. et al. (2022). Improving the model of object detection on aerial photographs and video in unmanned aerial systems. Eastern-European Journal of Enterprise Technologies, 1 (9 (115)), 24–34. doi: https://doi.org/10.15587/1729-4061.2022.252876

- Teslenko, A., Chernukha, A., Bezuglov, O., Bogatov, O., Kunitsa, E., Kalyna, V. et al. (2019). Construction of an algorithm for building regions of questionable decisions for devices containing gases in a linear multidimensional space of hazardous factors. Eastern-European Journal of Enterprise Technologies, 5 (10 (101)), 42–49. doi: https://doi.org/10.15587/1729-4061.2019.181668

- Kovaliova, O., Pivovarov, O., Kalyna, V., Tchoursinov, Y., Kunitsia, E., Chernukha, A. et al. (2020). Implementation of the plasmochemical activation of technological solutions in the process of ecologization of malt production. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 26–35. doi: https://doi.org/10.15587/1729-4061.2020.215160

- Tariq, M., Qureshi, A. K., Karim, S., Sirajuddin, M., Abbas, N., Imran, M., Shirazi, J. H. (2021). Synthesis, characterization and fuel parameters analysis of linseed oil biodiesel using cadmium oxide nanoparticles. Energy, 222, 120014. doi: https://doi.org/10.1016/j.energy.2021.120014

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. doi: https://doi.org/10.15587/1729-4061.2020.200026

- Varas Condori, M. A., Pascual Chagman, G. J., Barriga-Sanchez, M., Villegas Vilchez, L. F., Ursetta, S., Guevara Pérez, A., Hidalgo, A. (2020). Effect of tomato (Solanum lycopersicum L.) lycopene-rich extract on the kinetics of rancidity and shelf-life of linseed (Linum usitatissimum L.) oil. Food Chemistry, 302, 125327. doi: https://doi.org/10.1016/j.foodchem.2019.125327

- Chernukha, A., Chernukha, A., Ostapov, K., Kurska, T. (2021). Investigation of the Processes of Formation of a Fire Retardant Coating. Materials Science Forum, 1038, 480–485. doi: https://doi.org/10.4028/www.scientific.net/msf.1038.480

- Chernukha, A., Chernukha, A., Kovalov, P., Savchenko, A. (2021). Thermodynamic Study of Fire-Protective Material. Materials Science Forum, 1038, 486–491. doi: https://doi.org/10.4028/www.scientific.net/msf.1038.486

- Korchak, M., Bliznjuk, O., Nekrasov, S., Gavrish, T., Petrova, O., Shevchuk, N. et al. (2022). Development of rational technology for sodium glyceroxide obtaining. Eastern-European Journal of Enterprise Technologies, 5 (6 (119)), 15–21. doi: https://doi.org/10.15587/1729-4061.2022.265087

- Petik, I., Belinska, A., Kunitsia, E., Bochkarev, S., Ovsiannikova, T., Kalyna, V. et al. (2021). Processing of ethanol-containing waste of oil neutralization in the technology of hand cleaning paste. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 23–29. doi: https://doi.org/10.15587/1729-4061.2021.225233

- Sytnik, N., Kunitsa, E., Mazaeva, V., Chernukha, A., Bezuglov, O., Bogatov, O. et al. (2020). Determination of the influence of natural antioxidant concentrations on the shelf life of sunflower oil. Eastern-European Journal of Enterprise Technologies, 4 (11 (106)), 55–62. doi: https://doi.org/10.15587/1729-4061.2020.209000

- Sytnik, N., Kunitsia, E., Mazaeva, V., Kalyna, V., Chernukha, A., Vazhynskyi, S. et al. (2021). Rational conditions of fatty acids obtaining by soapstock treatment with sulfuric acid. Eastern-European Journal of Enterprise Technologies, 4 (6 (112)), 6–13. doi: https://doi.org/10.15587/1729-4061.2021.236984

- Ghosh, M., Upadhyay, R., Mahato, D. K., Mishra, H. N. (2019). Kinetics of lipid oxidation in omega fatty acids rich blends of sunflower and sesame oils using Rancimat. Food Chemistry, 272, 471–477. doi: https://doi.org/10.1016/j.foodchem.2018.08.072

- Korchak, M., Bragin, O., Petrova, O., Shevchuk, N., Strikha, L., Stankevych, S. et al. (2022). Development of transesterification model for safe technology of chemical modification of oxidized fats. Eastern-European Journal of Enterprise Technologies, 6 (6 (120)), 14–19. doi: https://doi.org/10.15587/1729-4061.2022.266931

- de Jesus, J. H. F., Ferreira, A. P. G., Szilágyi, I. M., Cavalheiro, E. T. G. (2020). Thermal behavior and polymorphism of the antioxidants: BHA, BHT and TBHQ. Fuel, 278, 118298. doi: https://doi.org/10.1016/j.fuel.2020.118298

- Faas, N., Röcker, B., Smrke, S., Yeretzian, C., Yildirim, S. (2020). Prevention of lipid oxidation in linseed oil using a palladium-based oxygen scavenging film. Food Packaging and Shelf Life, 24, 100488. doi: https://doi.org/10.1016/j.fpsl.2020.100488

- Gomes, M. H. G., Kurozawa, L. E. (2021). Influence of rice protein hydrolysate on lipid oxidation stability and physico-chemical properties of linseed oil microparticles obtained through spray-drying. LWT, 139, 110510. doi: https://doi.org/10.1016/j.lwt.2020.110510

- Kūka, M., Čakste, I., Kūka, P. (2018). Inhibition of Formation of Conjugated Dienes in Linseed Oil. Proceedings of the Latvian Academy of Sciences. Section B. Natural, Exact, and Applied Sciences., 72 (2), 80–84. doi: https://doi.org/10.2478/prolas-2018-0013

- Edimecheva, I. P., Sosnovskaya, A. A., Shadyro, O. I. (2020). The application of natural and synthetic antioxidants to increase the oxidation resistance of linseed oil. Food Industry: Science and Technology, 13 (4 (50)), 41–51. doi: https://doi.org/10.47612/2073-4794-2020-13-4(50)-41-51

- Epaminondas, P. S., Araújo, K. L. G. V., Nascimento, J. A., Souza, A. L., Rosenhaim, R., Souza, A. G. (2014). Assessment of the antioxidant effect of ethanol extract of Allium sativum L., isolated and/or synergistically associated with synthetic antioxidants, applied to linseed oil. Journal of Thermal Analysis and Calorimetry, 120 (1), 617–625. doi: https://doi.org/10.1007/s10973-014-3870-8

- Prakash, K., Naik, S. N., Yadav, U. (2020). Effects of Sesame Seed Oil (Black /White) as a Natural Antioxidant on the Oxidative and Frying Stability of Linseed Oil. European Journal of Nutrition & Food Safety, 133–146. doi: https://doi.org/10.9734/ejnfs/2020/v12i1130329

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Natalia Sytnik, Mykola Korchak, Serhii Nekrasov, Vitalii Herasymenko, Roman Mylostyvyi, Tetiana Ovsiannikova, Tetiana Shamota, Valentyna Mohutova, Nataliia Ofilenko, Inna Choni

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.