Identification of the nature of defects arising in the production of continuously cast pipe billets for the oil and gas industry

DOI:

https://doi.org/10.15587/1729-4061.2023.284387Keywords:

pipe steel, non-metallic inclusions, longitudinal cracks, oil and gas industry, continuous castingAbstract

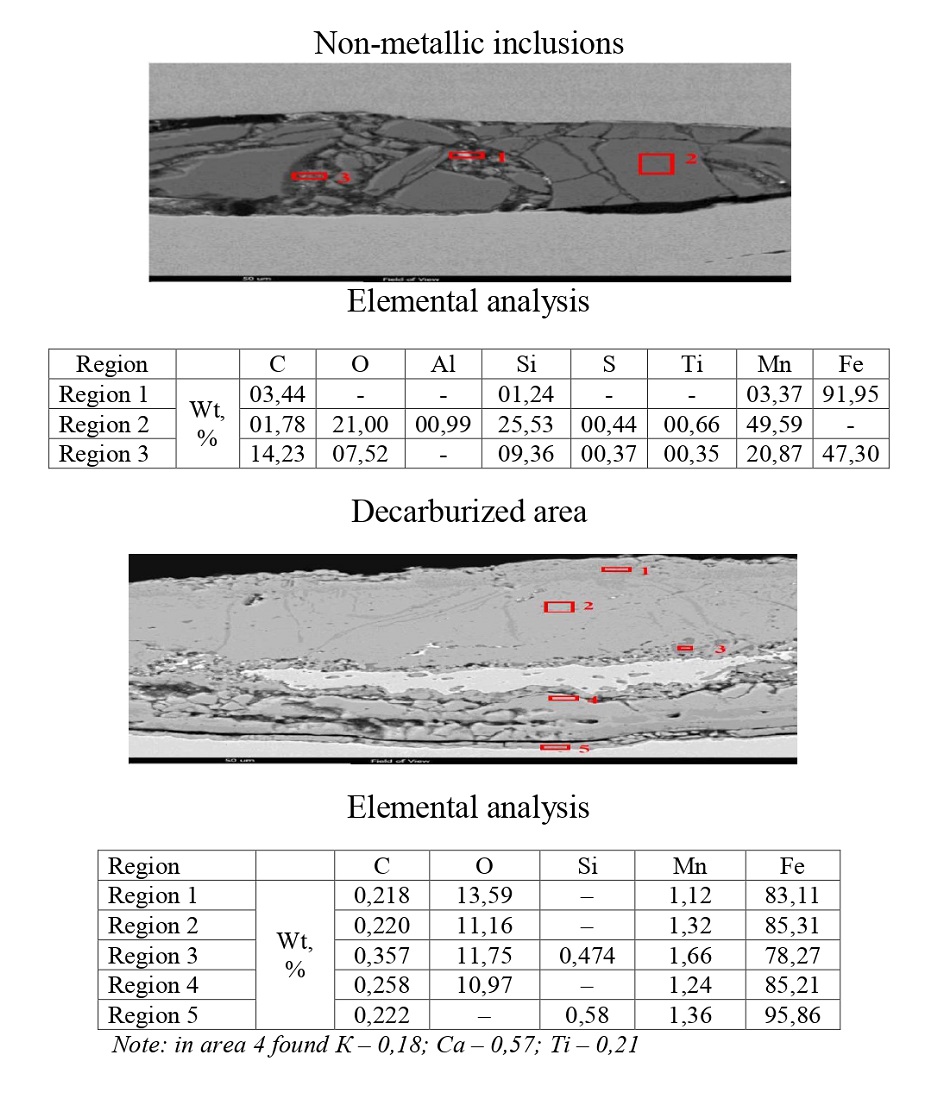

The paper presents the results of studies of defects that occur in the production of continuously cast pipe blanks for the oil and gas industry. It is shown that the use of the technology of continuous casting of pipe billets in comparison with the traditional methods of pouring liquid steel into a mold has a number of advantages, among which is the high productivity of the technological process. However, it was noted that in many cases, an abnormally high degree of contamination with non-metallic inclusions is observed in the structure of the steel of continuously cast pipe billets.

It was revealed that the largest inclusions are oxides of silicon and manganese. On the surface of the pipes, there are defects in the form of oxide spots, near which there are large non-metallic inclusions. On the surface of the oxide spot, the presence of iron oxides in the form of scale is found, which is a consequence of the secondary oxidation of the metal by air oxygen.

A mechanism for the development of oxide spots and decarburized strips in pipe billets has been determined, which consists in the formation of defects in the form of scratches and cracks on the surface before rolling. These defects during heating for rolling lead to the oxidation of the metal and the formation of scale on the surface of the pipe blanks. The results of experimental studies on the development of recommendations for improving the quality of the initial metal of seamless pipes for the oil and gas industry are presented. The study of the microstructure of steel and the assessment of its contamination with non-metallic inclusions were carried out on optical and electron microscopes, and the mechanical properties of pipe blanks were studied by standard methods

References

- Rakhmanov, S. R., Mamedov, A. T., Bespalko, V. N., Topolov, V. L., Azimov, A. A. (2017). Machine-building materials (reference data, terms and definitions). Dnipro-Baku, 410.

- Rakhmanov, S. R., Tоpolov, V. L., Gasik, M. İ., Mamedov, A. T., Azimov, A. A. (2017). Processes and machines of electrometallurgical production. Baku-Dnepr: "System Technologies" - "Sabah" Publishing House, 568.

- Barazyntseva, E. P., Glazunova, N. A., Razhkova, O. V. (2002). Transformatsiya defektov makrostruktury nepreryvnolitoy zagotovki pri proizvodstve besshovnykh goryachekatannykh trub na RUP «PMZ». Lit'e i metallurgiya, 4 (49), 38–40.

- Naumenko, E. A., Rozhkova, O. V., Kovaleva, I. A. (2023). Comprehensive study of characteristic signs of defects detected during magnetic powder control at the final stage of production of seamless hot‑rolled pipes. Litiyo i Metallurgiya (FOUNDRY PRODUCTION AND METALLURGY), 1, 69–72. doi: https://doi.org/10.21122/1683-6065-2023-1-69-72

- Karimov, R. İ. (2020). Features of removal of Phosphorus and sulfur from Remlturing stock turing electric arc melting of Steel. International journal of Control and Automation, 13 (1), 137–159.

- Karimov, R. İ. (2020). Thermodynamic features of increasing the efficiency of metallurgical processes during electric steel melting. Rensta San Gregorio Ecuador, 2, 845–864.

- Smolyakov, A. S., Shakhov, S. I., Kerimov, R. (2017). Modernization of Baku Steel Company Metallurgical Plant Section CBCM for Producing Round Pipe Billets. Metallurgist, 61 (7-8), 543–548. doi: https://doi.org/10.1007/s11015-017-0530-9

- Smolyakov, A. S., Shakhov, S. I., Kerimov, R. I., Rafiev, O. Yu. (2017). Recon-struction of the existing sectional CCM of Baku Steel Company for the purpose of casting round billets for the needs of the pipe industry. Black Metallurgy Bulletin, 1 (1405), 43–46.

- Shakhov, S. I., Kerimov, R. I. (2018). Modernization of the existing sectional continuous casting machine of the Baku Steel Company plant in order to produce round billets. Heavy engineering, 5, 9–13.

- Shakhov, S. I., Kerimov, R. I. (2017). Completion of the reconstruction of the sectional continuous casting machine of the Baku Steel Company plant in order to produce round pipe billets. Ferrous metallurgy, 3, 63–65.

- Sivak, B. A., Shakhov, S. I., Vdovin, K. N., Rogachikov, Yu. M., Kerimov, R. I. (2020). Development of a System for Electromagnetic Stirring of Liquid Steel in Molds of Billet and Bloom CCMS. Metallurgist, 63 (9-10), 910–914. doi: https://doi.org/10.1007/s11015-020-00909-w

- Babanli, M., Karimov, R., Bayramov, A., Abbasov, I. I. (2019). An impact of the ladle lining on the refining of reinforced steel when blowing with powders. Eastern-European Journal of Enterprise Technologies, 5 (1 (101)), 65–71. doi: https://doi.org/10.15587/1729-4061.2019.178015

- Kerimov, R. I., Jafarova, A. A. (2017). Investigation of the quality of a broken casing sleeve made by Baku Steel Company. Scientific notes. AzTU, 4, 191–198.

- Kudrin, V. A. (2003). Theory and technology of steel production. Moscow: Mir, LLC "Izdotstvo" AST, 528.

- Shakhov, S. I., Sivak, B. A., Vdovin, K. N., Shakhov, D. S., Kerimov, R. I., Bairamov, А. Т. (2020). Perfection of the equipment of electromagnetic stirring in moulds of billet and bloom CCM. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information, 76 (10), 1014–1020. doi: https://doi.org/10.32339/0135-5910-2020-10-1014-1020

- Bayramov, A. T. (2022). Reserves for increasing the efficiency of out-of-furnace processing of electric steel. International scientific and practical conference "Youth, science, education: Actual issues of achievement and innovation". Penza.

- Kerimov, R. I. (2019). Improving steel melting intensity in the process of electrosmelting from waste and pellets (HBI). Eastern-European Journal of Enterprise Technologies, 3 (1 (99)), 35–42. doi: https://doi.org/10.15587/1729-4061.2019.168352

- Babenko, A. A., Zhuchkov, V. I., Smirnov, L. A., Sychev, A. V., Akberdin, A. A., Kim, A. S. et al. (2015). Production technology for low-carbon, low-sulfur boron steel. Steel in Translation, 45 (11), 883–886. doi: https://doi.org/10.3103/s0967091215110029

- Velichko, O. G., Stoyanov, O. M., Batchenko, B. M., Nizyaev, K. G. (2016). Steel quality improvement technologies. Dnipro, 196.

- Minenko, A. S., Radevich, E. V. (2018). Mathematical modeling of the process of metal crystallization. Problems of Artificial Intelligence, 1 (8), 13–23.

- Kazakov, A. A., Kovalev, P. V., Zinchenko, S. D. et al. (2007). The nature of defects of hot-rolled sheet from tubular grades of steel. Part 1. Defects of a steelmaking nature. Black Metals, 11, 8–15.

- Mamedov, A. T., Ismailov, N. Sh., Jafarova, V. N. (2022). Ladle Treatment of Structural Steel: Physical Modeling. Russian Engineering Research, 42 (12), 1228–1233. doi: https://doi.org/10.3103/s1068798x22120218

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Arif Mammadov, Agil Babaev, Nizami Ismailov, Mukhtar Huseinov, Faiq Guliyev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.