Determining the tension of complex chemical threads during interaction with guide surfaces

DOI:

https://doi.org/10.15587/1729-4061.2023.284599Keywords:

thread tension, chemical thread, guide surface, surface curvature, angle of coverageAbstract

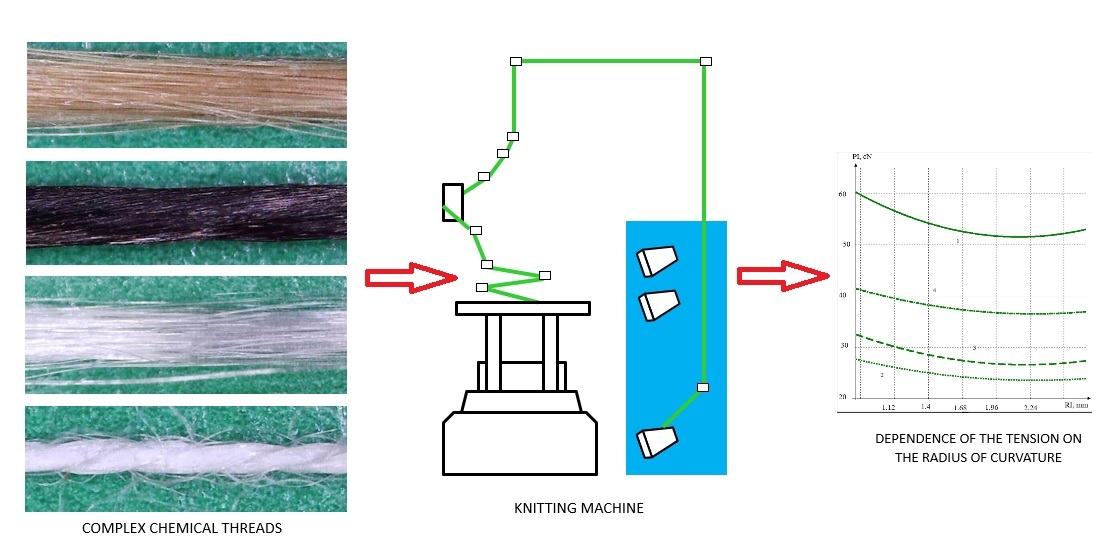

This paper reports a study to determine the tension of complex chemical threads made of Kevlar, carbon, polyethylene, and meta-aramid when interacting with the working bodies of knitting machines in the process of forming technical knitwear. An increase in tension after the guide surface of the working body due to a change in the value of the friction forces in the contact zone was established. It has been proven that the tension of the selected complex chemical threads after the guide surface of the working body is affected by the tension of the thread in front of the guide surface of the working body of the knitting machine. Also, the amount of tension is affected by the radius of curvature of the cylindrical guide surface of the working body and the angle of thread coverage of the guide surface of the working body of the knitting machine. This has made it possible to determine thread tension even at the initial stage of designing the technological process of thread processing on knitting machines, during the production of technical knitwear. On the basis of experimental studies for Kevlar, carbon, polyethylene, and meta-aramid complex threads, regression dependences of the stress after the cylindrical guide surface of the working body of the knitting machine were constructed. The analysis of regression dependences made it possible to establish the value of the radius of curvature of the guides when the tension of complex chemical threads before the knitting zone on knitting machines would take a minimum value. This will minimize the stress on complex threads during their processing.

So, there are reasons to assert the possibility of directed regulation of the process of changing the tension of Kevlar, carbon, polyethylene, and meta-aramid complex threads during the formation of technical knitwear on knitting machines by selecting the value of the geometric parameters of the guides

References

- Shcherban’, V., Makarenko, J., Petko, A., Melnyk, G., Shcherban’, Y., Shchutska, H. (2020). Computer implementation of a recursion algorithm for determining the tension of a thread on technological equipment based on the derived mathematical dependences. Eastern-European Journal of Enterprise Technologies, 2 (1 (104)), 41–50. doi: https://doi.org/10.15587/1729-4061.2020.198286

- de Vasconcelos, F. B., Marcicano, J. P. P., Sanches, R. A. (2015). Influence of yarn tension variations before the positive feed on the characteristics of knitted fabrics. Textile Research Journal, 85 (17), 1864–1871. doi: https://doi.org/10.1177/0040517515576327

- Barburski, M. (2014). Analysis of the mechanical properties of conveyor belts on the three main stages of production. Journal of Industrial Textiles, 45 (6), 1322–1334. doi: https://doi.org/10.1177/1528083714559567

- Wang, W., Huang, G. (2009). Characterisation and utilization of natural coconut fibres composites. Materials & Design, 30 (7), 2741–2744. doi: https://doi.org/10.1016/j.matdes.2008.11.002

- Koo, Y.-S., Kim, H.-D. (2002). Friction of Cotton Yarn in Relation to Fluff Formation on Circular Knitting Machines. Textile Research Journal, 72 (1), 17–20. doi: https://doi.org/10.1177/004051750207200103

- Döonmez, S., Marmarali, A. (2004). A Model for Predicting a Yarn’s Knittability. Textile Research Journal, 74 (12), 1049–1054. doi: https://doi.org/10.1177/004051750407401204

- Shcherban’, V., Makarenko, J., Melnyk, G., Shcherban’, Y., Petko, A., Kirichenko, A. (2019). Effect of the yarn structure on the tension degree when interacting with high-curved guides. Fibres and Textiles, 26 (4), 59–68. Available at: http://vat.ft.tul.cz/2019/4/VaT_2019_4_8.pdf

- Liu, X., Chen, N., Feng, X. (2008). Effect of Yarn Parameters on the Knittability of Glass Ply Yarn. Fibres & Textiles in Eastem Europe, 16, 90–93.

- Shcherban', V. Yu. (1990). Determining the technological forces during beating-up in the production of multilayer industrial fabrics. Izvestiya Vysshikh Uchebnykh Zavedenii. Technology of Textile Industry, 3 (195), 44–47. Available at: https://er.knutd.edu.ua/handle/123456789/17888

- Hammersley, M. J. (1973). 7—a simple yarn-friction tester for use with knitting yarns. The Journal of The Textile Institute, 64 (2), 108–111. doi: https://doi.org/10.1080/00405007308630420

- Kovar, R. (2007). Impact of directions on frictional properties of a knitted fabric. Fibres and Textiles, 14 (2), 15–20. Available at: http://vat.ft.tul.cz/Archive/VaT_2007_2.pdf

- Shcherban’, V., Kolysko, O., Melnyk, G., Sholudko, M., Shcherban’, Y., Shchutska, G. (2020). Determining tension of yarns when interacting with guides and operative parts of textile machinery having the torus form. Fibres and Textiles, 4, 87–95. Available at: http://vat.ft.tul.cz/2020/4/VaT_2020_4_12.pdf

- Weber, M. O., Ehrmann, A. (2012). Necessary modification of the Euler–Eytelwein formula for knitting machines. Journal of the Textile Institute, 103 (6), 687–690. doi: https://doi.org/10.1080/00405000.2011.598665

- Sodomka, L., Chrpová, E. (2008). Method of determination of euler friction coefficients of textiles. Fibres and Textiles, 2-3, 28–33. Available at: http://vat.ft.tul.cz/Archive/VaT_2008_2_3.pdf

- Vanleeuw, B., Carvelli, V., Barburski, M., Lomov, S. V., van Vuure, A. W. (2015). Quasi-unidirectional flax composite reinforcement: Deformability and complex shape forming. Composites Science and Technology, 110, 76–86. doi: https://doi.org/10.1016/j.compscitech.2015.01.024

- Xue, P., Cao, J., Chen, J. (2005). Integrated micro/macro-mechanical model of woven fabric composites under large deformation. Composite Structures, 70 (1), 69–80. doi: https://doi.org/10.1016/j.compstruct.2004.08.013

- Dow, N. F., Tranfield, G. (1970). Preliminary Investigations of Feasibility of Weaving Triaxial Fabrics (Doweave). Textile Research Journal, 40 (11), 986–998. doi: https://doi.org/10.1177/004051757004001106

- Yakubitskaya, I. A., Chugin, V. V., Shcherban', V. Yu. (1997). Differential equations for relative yarn movement in the end sections of the channel in the winding drum. Izvestiya Vysshikh Uchebnykh Zavedenii. Technology of Textile Industry, 6, 50–54.

- Schwartz, P., Fornes, R., Mohamed, M. (1982). An Analysis of the Mechanical Behavior of Triaxial Fabrics and the Equivalency of Conventional Fabrics. Textile Research Journal, 52 (6), 388–394. doi: https://doi.org/10.1177/004051758205200606

- Pac, M. J., Bueno, M.-A., Renner, M., El Kasmi, S. (2001). Warm-Cool Feeling Relative to Tribological Properties of Fabrics. Textile Research Journal, 71 (9), 806–812. doi: https://doi.org/10.1177/004051750107100910

- Naylor, G. R., Wilson, C. A., Laing, R. M. (2016). Thermal and water vapor transport properties of selected lofty nonwoven products. Textile Research Journal, 87 (12), 1413–1424. doi: https://doi.org/10.1177/0040517516654104

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Volodymyr Shcherban, Oksana Kolysko, Gennadij Melnyk, Yury Shcherban, Valentin Ishchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.