Визначення впливу параметрів зварювання орбітальної труби на механічні властивості з використанням труби SS316L

DOI:

https://doi.org/10.15587/1729-4061.2023.287397Ключові слова:

орбітальне зварювання труб, газовольфрамове дугове зварювання, SS316L, міцність на розрив, мікротвердістьАнотація

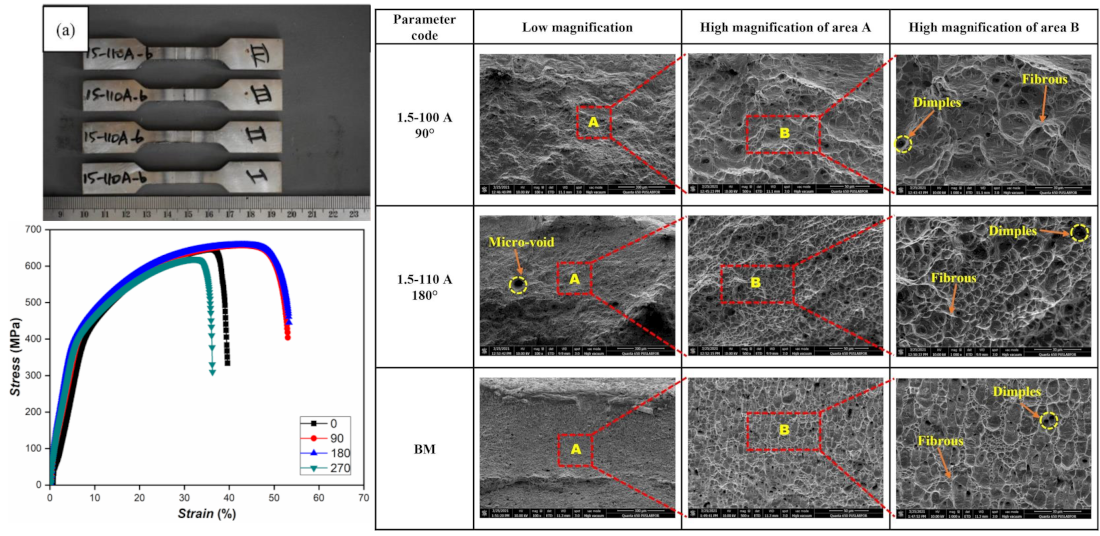

Трубопровідні системи відіграють ключову роль у різних галузях промисловості, слугуючи як рятівні для транспортування таких матеріалів, як нафта, вода та газ. Серед методів зварювання орбітальне зварювання труб, зокрема дугове зварювання газовою вольфрамовою дугою без присадочного металу, є методом підгонки для з’єднання цих критичних систем трубопроводів. У цьому дослідженні розглядалося орбітальне зварювання труб SS316L із зовнішнім діаметром 114 мм і товщиною 3 мм. Основна мета полягала в тому, щоб ретельно оцінити міцність на розрив і мікротвердість зварного шва. Постійний струм і три швидкості зварювання – 1,3, 1,4 і 1,5 мм/с – досягли цієї мети. Крім того, експерименти зі зварювання охоплювали положення труб під кутами 0°, 90°, 180° і 270°. Спочатку готували необхідні інструменти та об’єкти для випробувань, а потім зварювали досліджувані матеріали. Завершальним етапом були випробування міцності на розрив і мікротвердості. У цьому дослідженні використовувався прототип орбітального зварювального обладнання для 5G. Метод 5G вимагає горизонтального зварювання з вертикальною віссю труби. У дослідженні використовувався стандартизований випробувальний матеріал, сумісний з ASTM E-8M, для точних і повторюваних вимірювань міцності на розрив. Ця стандартизація забезпечила надійність результатів. Одним із важливих висновків було те, що зварювання зі швидкістю 1,4 мм/с при положенні труби під кутом 270° зі струмом 110 А дало максимальну міцність на розрив. Це показує, що ці умови найкращі для зварювання труб з нержавіючої сталі типу SS316L із зовнішнім діаметром 114 мм і товщиною 3 мм. Як не дивно, випробування мікротвердості показали, що якість горизонтального розподілу зварювання знизилася на 1,4 мм/с. Це означає, що можуть знадобитися подальші експерименти для точного налаштування параметрів зварювання для оптимізації процесу та досягнення вищих значень мікротвердості.

Посилання

- Singh, N. K., Pradhan, S. K. (2020). Experimental and numerical investigations of pipe orbital welding process. Materials Today: Proceedings, 27, 2964–2969. doi: https://doi.org/10.1016/j.matpr.2020.04.902

- Harris, I. D. (2011). Welding advances in tube and pipe applications. Welding Journal, 90 (6), 58–63. Available at: https://www.researchgate.net/publication/291636610_Welding_Advances_in_Tube_and_Pipe_Applications

- Rahimi, A., Shamanian, M. (2019). The PC-GTAW of Ti–6Al–4V Thin Sheets and Its Effects on Mechanical and Microstructural Properties. Metallography, Microstructure, and Analysis, 8 (6), 871–879. doi: https://doi.org/10.1007/s13632-019-00595-4

- Park, J.-H., Kim, S.-H., Moon, H.-S., Kim, M.-H. (2019). Influence of Gravity on Molten Pool Behavior and Analysis of Microstructure on Various Welding Positions in Pulsed Gas Metal Arc Welding. Applied Sciences, 9 (21), 4626. doi: https://doi.org/10.3390/app9214626

- Okano, S., Mochizuki, M. (2017). Transient distortion behavior during TIG welding of thin steel plate. Journal of Materials Processing Technology, 241, 103–111. doi: https://doi.org/10.1016/j.jmatprotec.2016.11.006

- Pal, K., Pal, S. K. (2010). Effect of Pulse Parameters on Weld Quality in Pulsed Gas Metal Arc Welding: A Review. Journal of Materials Engineering and Performance, 20 (6), 918–931. doi: https://doi.org/10.1007/s11665-010-9717-y

- Dak, G., Joshi, J., Yadav, A., Chakraborty, A., Khanna, N. (2020). Autogenous welding of copper pipe using orbital TIG welding technique for application as high vacuum boundary parts of nuclear fusion devices. International Journal of Pressure Vessels and Piping, 188, 104225. doi: https://doi.org/10.1016/j.ijpvp.2020.104225

- Karthikeyan, M., Naikan, V. N., Narayan, R., Sudhakar, D. P. (2016). Orbital TIG welding process parameter optimization using design of experiment for satellite application. International Journal of Performability Engineering, 12 (2), 155. Available at: http://www.ijpe-online.com/EN/10.23940/ijpe.16.2.p155.mag

- Liu, Y., Wang, P., Fang, H., Ma, N. (2021). Characteristics of welding distortion and residual stresses in thin-walled pipes by solid-shell hybrid modelling and experimental verification. Journal of Manufacturing Processes, 69, 532–544. doi: https://doi.org/10.1016/j.jmapro.2021.08.014

- Liu, C., Zhang, J. X. (2009). Numerical simulation of transient welding angular distortion with external restraints. Science and Technology of Welding and Joining, 14 (1), 26–31. doi: https://doi.org/10.1179/136217108x341175

- Garcia, J. A. O. de, Dias, N. S., Lima, G. L. de, Pereira, W. D. B., Nogueira, N. F. (2010). Advances of orbital gas tungsten arc welding for Brazilian space applications - experimental setup. Journal of Aerospace Technology and Management, 2 (2), 211–218. doi: https://doi.org/10.5028/jatm.2010.02026610

- Feng, J. C., Rathod, D. W., Roy, M. J., Francis, J. A., Guo, W., Irvine, N. M. et al. (2017). An evaluation of multipass narrow gap laser welding as a candidate process for the manufacture of nuclear pressure vessels. International Journal of Pressure Vessels and Piping, 157, 43–50. doi: https://doi.org/10.1016/j.ijpvp.2017.08.004

- Widyianto, A., Baskoro, A. S., Kiswanto, G. (2022). Investigation on Weld Characteristic, Welding Position, Microstructure, and Mechanical Properties in Orbital Pulse Current Gas Tungsten Arc Welding of AISI 304L Stainless Steel Pipe. International Journal of Technology, 13 (3), 473. doi: https://doi.org/10.14716/ijtech.v13i3.3134

- Widyianto, A., Baskoro, A. S., Kiswanto, G., Ganeswara, M. F. G. (2021). Effect of welding sequence and welding current on distortion, mechanical properties and metallurgical observations of orbital pipe welding on SS 316L. Eastern-European Journal of Enterprise Technologies, 2 (12 (110)), 22–31. doi: https://doi.org/10.15587/1729-4061.2021.228161

- Sridhar, P. V. S. S., Biswas, P., Mahanta, P. (2020). Effect of process parameters on bead geometry, tensile and microstructural properties of double-sided butt submerged arc welding of SS 304 austenitic stainless steel. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 42 (10). doi: https://doi.org/10.1007/s40430-020-02636-4

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Eko Prasetyo, Ario Sunar Baskoro, Agus Widyianto, Gandjar Kiswanto

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.