Development of an algorithm for the reasoned selection of machines for leather garments manufacturing

DOI:

https://doi.org/10.15587/1729-4061.2023.287482Keywords:

sewing machine, machine selection, machine operation, artificial leather, process graphAbstract

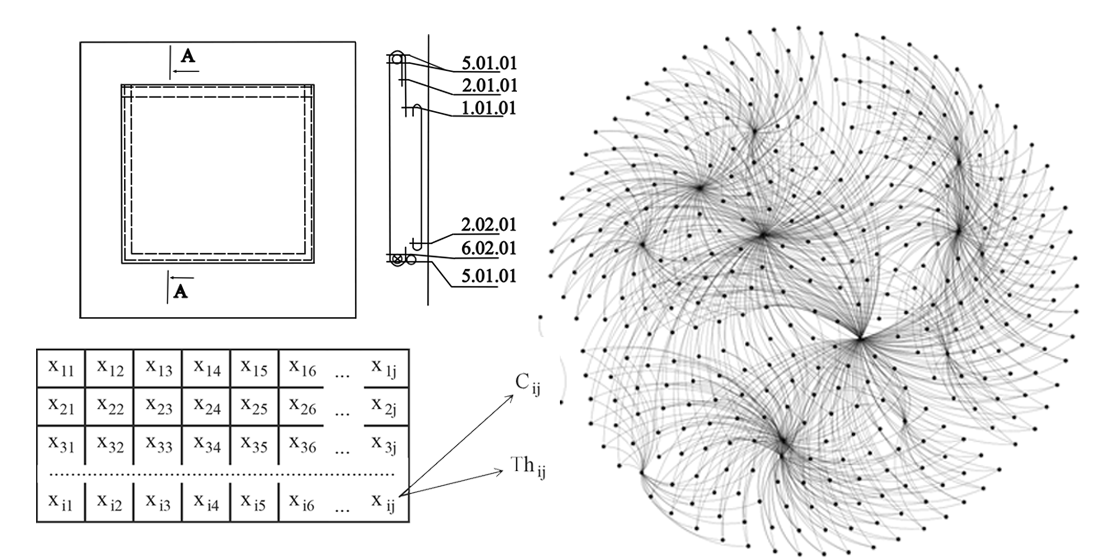

The technology of processing clothing elements is very mobile and changes with the appearance of new materials and equipment. The selected design and technological solutions that ensure the conformity of aesthetic properties and requirements can be satisfied through continuous improvement of sewing production technologies. This study aims to develop an algorithm for choosing the optimal equipment, taking into account the material parameters and the permissible requirements for the technological process of manufacturing sewing products from artificial leather. As a result of the analysis of the range of sewing machines and manufacturing companies, Juki sewing machines were chosen to build a complex matrix of machine equipment. A morphological scheme of the selection process and a mathematical description of the two-dimensional matrix of elements have been developed. That has made it possible to reflect the simultaneous consideration of all process components and their influence on the technological parameters of the machine. The database of the parameters of the equipment selection system was built in the form of matrix elements: a matrix of the type of operations, a matrix of material coatings, a matrix of the base of materials, a matrix of machine assignments, and a matrix of qualifications. Each matrix is a production rule for making a decision at a separate selection stage. The operation matrix was constructed using the TechLab mobile application, which includes 50 processing schemes for artificial leather products. The analysis of the schemes has made it possible to determine the frequency of occurrence of types of seams for processing artificial leather products: 1.01.01 (28.75 %), 2.01.01 (16.75 %), 1.06.02 (11.00 %), 2.02.01 (15.50 %), 5.01.01 (24.25 %), 6.02.01 (3.75 %). The mathematical notation of the algorithm for choosing the optimal machine equipment has made it possible to visualize the structure of the process using a graph. The graph was built using Gephi. Such a notation takes into account the qualification of the worker, the type of technological operation, and the material’s properties, including the material’s thickness, coating, and base.

References

- Kim, M., Ahn, J., Kang, J., Kim, S. (2020). A Systematic Review on Smart Manufacturing in the Garment Industry. Fashion & Textile Research Journal, 22 (5), 660–675. doi: https://doi.org/10.5805/sfti.2020.22.5.660

- Ulutaş, A. (2020). New Grey Integrated Model to Solve Machine Selection Problem for a Textile Company. Fibres and Textiles in Eastern Europe, 28 (1 (139)), 20–25. doi: https://doi.org/10.5604/01.3001.0013.5853

- Shahriar, M. M., Parvez, M. S., Talapatra, S. (2022). Hierarchizing the Product Characteristics of Industrial Plain Sewing Machine for Making Best Purchase Decision. Mathematical Problems in Engineering, 2022, 1–17. doi: https://doi.org/10.1155/2022/2578875

- Karakiş, E. (2021). Machine Selection for a Textile Company with CRITIC and MAUT Methods. European Journal of Science and Technology, 27, 842–848. doi: https://doi.org/10.31590/ejosat.994697

- Zakharkevich, O., Poluchovich, I., Kuleshova, S., Koshevko, J., Shvets, G., Shvets, A. (2021). “CloStyler” – mobile application to calculate the parameters of clothing blocks. IOP Conference Series: Materials Science and Engineering, 1031 (1), 012031. doi: https://doi.org/10.1088/1757-899x/1031/1/012031

- Zakharkevich, O., Koshevko, J., Shvets, G., Kuleshova, S., Bazyliuk, E., Paraska, O., Kazlacheva, Z. (2022). Development of the Mobile Application to Calculate Parameters of Underwear Patterns. Terotechnology XII Materials Research Proceedings, 24, 309–315. doi: https://doi.org/10.21741/9781644902059-45

- Boz, S., Birkocak, D. T., Necef, Ö. K., Kiliç, A., Öndoğan, Z. (2022). Investigation of sewing parameters caused fabric damages. AUTEX Conference Proceedings. Lodz, 40–44. doi: https://doi.org/10.34658/9788366741751.9

- Tama Birkocak, D. (2022). Effects of Needle Size and Sewing Thread on Seam Quality of Traditional Fabrics. Tekstil ve Konfeksiyon, 32 (3), 277–287. doi: https://doi.org/10.32710/tekstilvekonfeksiyon.1088043

- Meyer, M., Dietrich, S., Schulz, H., Mondschein, A. (2021). Comparison of the Technical Performance of Leather, Artificial Leather, and Trendy Alternatives. Coatings, 11 (2), 226. doi: https://doi.org/10.3390/coatings11020226

- Syabani, Muh. W., Devi, C., Hermiyati, I., Angkasa, A. D. (2020). The effect of PVC’s resin K-value on the mechanical properties of the artificial leather. Majalah Kulit, Karet, Dan Plastik, 35 (2), 75. doi: https://doi.org/10.20543/mkkp.v35i2.5639

- Watanabe, S., Tominaga, S., Horiuchi, T. (2020). The Difference in Impression between Genuine and Artificial Leather: Quantifying the Feeling of Authenticity. Journal of Perceptual Imaging, 3 (2), 020501-1-020501–020511. doi: https://doi.org/10.2352/j.percept.imaging.2020.3.2.020501

- Zakharkevich, O., Paraska, O., Koshevko, J., Shvets, G., Shvets, A., Zhylenko, T. (2023). Development of a Mobile Application to Study Sewing Techniques for Manufacturing Fur and Leather Clothes. Fibres & Textiles in Eastern Europe, 31 (2), 1–10. doi: https://doi.org/10.2478/ftee-2023-0011

- TechLab. Available at: https://play.google.com/store/apps/details?id=appinventor.ai_zbirvukladach.TL1&hl=uk&gl=US

- Ersöz, T., Tenbeli, R., Ersöz, F. (2021). Visual analysis of turkey's textile sector with Gephi complex network. Proceding of 11th International Symposium on Intelligent Manufacturing and Service System. Sakarya, 519–529. Available at: https://www.researchgate.net/publication/354331463_Visual_Analysis_of_Turkey%27s_Textile_Sector_with_Gephi_Complex_Network

- Zhylenko, T., Zakharkevich, O., Koshevko, J., Kuleshova, S. (2020). Parametrization of the hierarchical structure of the tree of pills emergence during pilling formation on textile materials. Vlakna a Textil, 4, 150–156. Available at: http://vat.ft.tul.cz/2020/4/VaT_2020_4_21.pdf

- Juki promyslovi shveini mashyny. Angeli. URL: https://angeli.net.ua/uk/juki

- Shveynoe oborudovanie Juki. Amtex. Available at: https://amtex.com.ua/brands/shvejnoe_oborydovanie_juki/

- Shveini mashynky Juki. Lapka. Available at: https://www.lapka.com.ua/ua/brand-juki.aspx

- Promyslovi shveini mashyny Juki. Sewtech. Available at: https://sewtech.com.ua/uk/promislovi-shvejni-mashini/brand-juki/

- Industrial sewing machines. Juki. Available at: https://www.juki.co.jp/en/products/industrial/

- ISO 4916:1991. Textiles – Seam types – Classification and terminology. Available at: https://www.iso.org/standard/10934.html

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oksana Zakharkevich, Tetyana Zhylenko, Julia Koshevko, Galina Shvets

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.