Identification of the impact of electric pulse action on the disintegration of a natural mineral

DOI:

https://doi.org/10.15587/1729-4061.2024.289556Keywords:

quartzite, electricpulse installation, grinding, cell, pulse discharge, rock-forming oxides, spectrophotometerAbstract

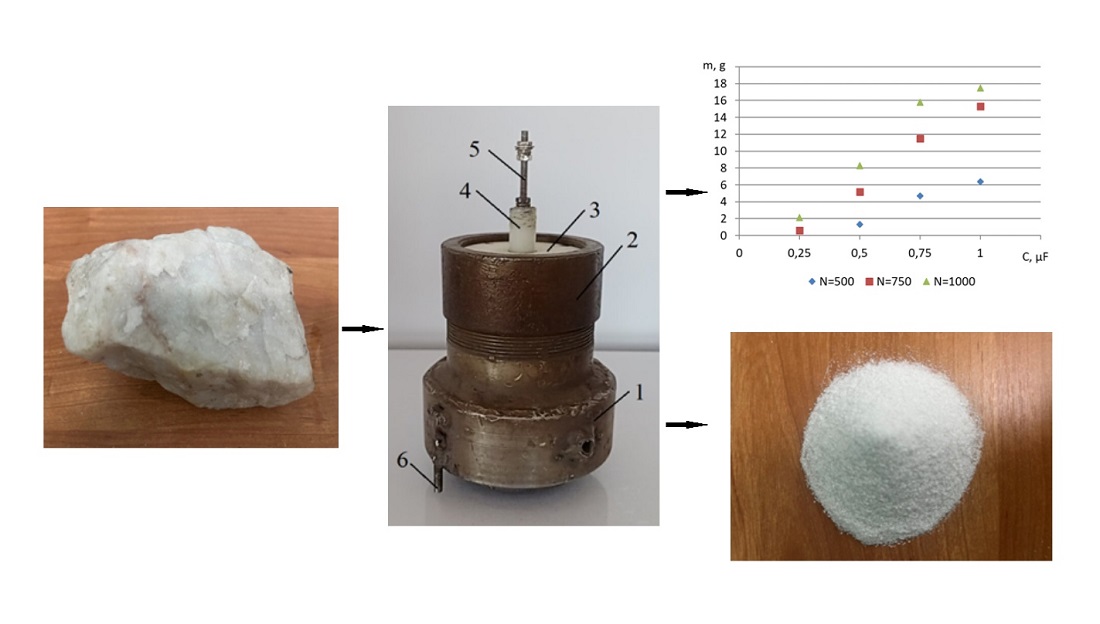

The work is devoted to the study of the electric pulse disintegration of a natural mineral. The object of the study is the natural mineral quartzite of the Aktas deposit of the Republic of Kazakhstan.

For the destruction and grinding of quartzite, a working cell of an electric pulse unit was developed. Electric pulse crushing is a modern technique for grinding a variety of materials, which provides the desired degree of grinding with a certain granulometric composition of the product and has a high ability of selective crushing. With the help of this technology, quartzite grinding was carried out with an increase in the capacity of capacitor banks from 0.25 mF to 1 mF, the pulse discharge voltage changed from 20 kV to 30 kV, the number of pulse discharges from 500 to 1,000, the inner diameter of the working cell from 60 mm to 80 mm. The results of the disintegration of a natural mineral by the electric pulse method allowed us to determine the degree of grinding of the finished product.

The obtained results can be used in the study and optimization of the extraction of natural minerals, which is important for ensuring the sustainable use of natural resources and balanced economic development.

Crushed quartzite is used in various industries, including the production of optical fibers, electronics and photovoltaic devices. A material with a particle diameter of 0.1 to 0.4 millimeters is used to create glass, ceramic and porcelain products, as well as insulation materials. Due to its homogeneous composition containing up to 98 % silicon oxide (SiO2) and excellent absorbent properties, quartz sand is also used as a filter material for water purification

References

- Gadyatov, V. G., Kiah, D. A., Zhidkova, S. A. (2010). In the case of the giant Quartz Peska in the resulting special pure quartz. News. Voronezh. Goss. UN-Ta. Ser. Geology, 2, 324–327.

- Vatalis, K. I., Charalambides, G., Benetis, N. P. (2015). Market of High Purity Quartz Innovative Applications. Procedia Economics and Finance, 24, 734–742. https://doi.org/10.1016/s2212-5671(15)00688-7

- Kurets, V. I., Solovyov, M. A., Zhuchkov, A. I., Barskaya, A. V. (2012). Electrical fracturing technologies for processing and destruction of materials. Study guide. Tomsk: TPU, 272.

- Andreev, S. E., Perov, V. A., Zverevich, V. V. (1980). Crushing, grinding and screening of minerals. Moscow: Nedra, 415.

- Yang, J., Zhu, P., Li, H., Li, Z., Huo, X., Ma, S. (2022). Research on the Relationship between Multi-Component Complex Ore and Its Component Minerals’ Grinding Characteristics under Abrasion Force. Minerals, 13 (1), 6. https://doi.org/10.3390/min13010006

- Korekina, M. A., Shtenberg, M. V., Lutoev, V. P., Shanina, S. N. (2020). Microelement composition of vein quartz of the Kuznechikhinskoe deposit (South Urals). Obogashchenie Rud, 23–29. https://doi.org/10.17580/or.2020.05.04

- Aliasgharzadeh-Polesangi, A., Abdollah-Pour, H., Farzin, Y. A. (2019). Nanostructured silicon production from quartzite ore by low-energy wet blending of the reagents, reduction in controlled atmosphere, and hydrometallurgy. Journal of Materials Research and Technology, 8 (1), 1014–1023. https://doi.org/10.1016/j.jmrt.2018.05.027

- Jiang, X., Chen, J., Wei, M., Li, F., Ban, B., Li, J. (2020). Effect of impurity content difference between quartz particles on flotation behavior and its mechanism. Powder Technology, 375, 504–512. https://doi.org/10.1016/j.powtec.2020.07.107

- Li, Y., Ma, Q., Xia, Z., Li, W., Lei, S. (2023). Influences of Na2CO3 roasting and H3PO4 hot-pressure leaching on the purification of vein quartz to achieve high-purity quartz. Hydrometallurgy, 218, 106065. https://doi.org/10.1016/j.hydromet.2023.106065

- Dal Martello, E., Bernardis, S., Larsen, R. B., Tranell, G., Di Sabatino, M., Arnberg, L. (2012). Electrical fragmentation as a novel route for the refinement of quartz raw materials for trace mineral impurities. Powder Technology, 224, 209–216. https://doi.org/10.1016/j.powtec.2012.02.055

- Potokin, A. S., Kolobov, V. V. (2022). Study of rocks from mining processing plants of the Murmansk region by use electric pulse disintegration materials method. Mining Industry Journal (Gornay Promishlennost), 5/2022, 135–138. https://doi.org/10.30686/1609-9192-2022-5-135-138

- Bulkairova, G., Nussupbekov, B., Bolatbekova, M., Khassenov, A., Nussupbekov, U., Karabekova, D. (2023). A research of the effect of an underwater electric explosion on the selectivity of destruction of quartz raw materials. Eastern-European Journal of Enterprise Technologies, 3 (12 (123)), 30–37. https://doi.org/10.15587/1729-4061.2023.279009

- Khassenov, A. K., Karabekova, D. Zh., Nussupbekov, B. R., Bulkairova, G. A., Kudusov, A. S., Alpysova, G. K., Bolatbekova, M. М. (2023). Investigation of the influences of pulsed electrical discharges on the grinding of quartz raw materials. Bulletin of the Karaganda University “Physics Series,” 110 (2), 93–99. https://doi.org/10.31489/2023ph2/93-99

- Kurytnik, I. P., Nussupbekov, B. R., Karabekova, D. Zh., Khassenov, A. K., Kazhikenova, A. Sh.(2018). Investigation of a crushing and grinding unit of an electropulseinstallation. Archives of Foundry Engineering, 18 (1), 61–64. https://doi.org/10.24425/118812

- Nusupbekov, B. R., Kussaiynov, K., Sakipova, S. E., Khassenov, А. K., Beisenbek, A. Zh. (2016). On Improvement of Technology of Complex Extraction of Rare and Trace Metals by Electropulse Method. Metallofizika I Noveishie Tekhnologii, 36 (2), 275–286. https://doi.org/10.15407/mfint.36.02.0275

- Yutkin, L. A. (1986). Elektrogidpavlicheskiy effekt i ego primenenie v promyshlennosti. Leningrad: Mashinostroenie, 253.

- Samilin, V., Biletsky, V. (2003). Special methods of mineral processing. Donetsk: Vostochny publishing house, 116.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ayanbergen Khassenov, Gulden Bulkairova, Dana Karabekova, Madina Bolatbekova, Gulnur Alpyssova, Arystan Kudussov, Perizat Kissabekova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.