Визначення впливу електроімпульсного дії на подрібнення природного мінералу

DOI:

https://doi.org/10.15587/1729-4061.2024.289556Ключові слова:

кварцит, електроімпульсна установка, подрібнення, комірка, імпульсний розряд, породоутворюючі оксиди, спектрофотометрАнотація

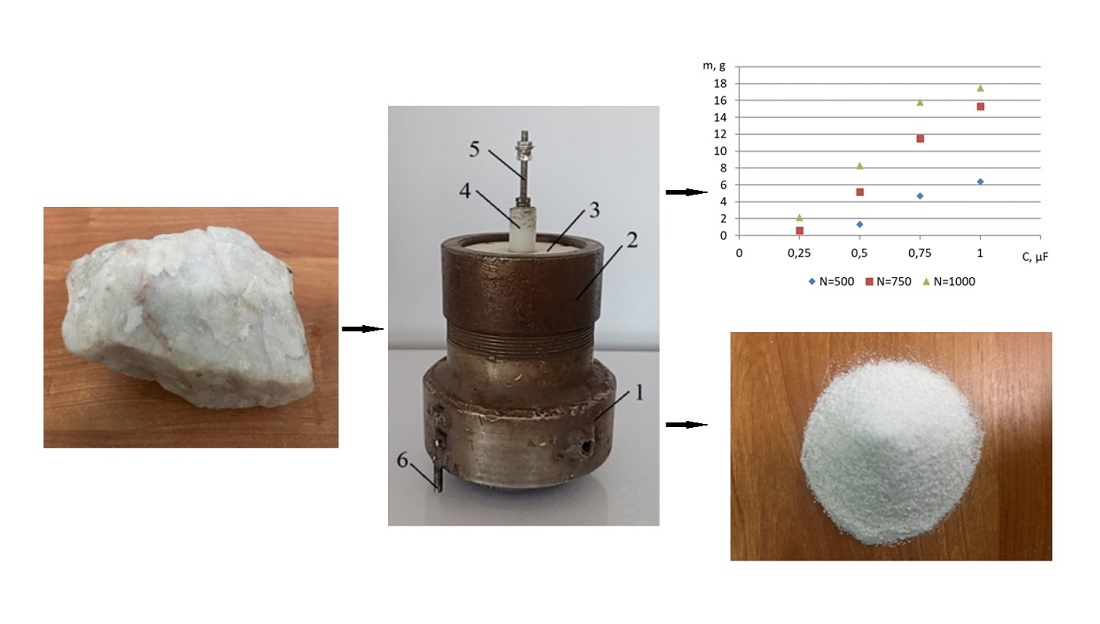

Робота присвячена дослідженню електроімпульсного подрібнення природного мінералу. Об’єктом дослідження є природний мінерал кварцит Актаського родовища Республіки Казахстан.

Для руйнування та подрібнення кварциту була розроблена робоча комірка електроімпульсної установки. Електроімпульсне подрібнення – це сучасний метод подрібнення різних матеріалів, що забезпечує задану ступінь подрібнення при певному гранулометричному складі продукту і володіє високою здатністю селективного дроблення. За допомогою даної технології проведено подрібнення кварциту зі збільшенням ємності конденсаторних батарей з 0,25 мкФ до 1 мкФ, зміною напруги імпульсного розряду з 20 кВ до 30 кВ, кількості імпульсних розрядів з 500 до 1000, внутрішнього діаметра робочої комірки з 60 мм до 80 мм. Результати подрібнення природного мінералу електроімпульсним методом дозволили визначити ступінь подрібнення готового продукту.

Отримані результати можуть бути використані при дослідженні та оптимізації видобутку природних корисних копалин, що важливо для забезпечення сталого використання природних ресурсів та збалансованого економічного розвитку.

Подрібнений кварцит використовується у різних галузях промисловості, включаючи виробництво оптичних волокон, електроніки та фотоелектричних пристроїв. Матеріал з діаметром частинок від 0,1 до 0,4 міліметра використовується для створення виробів зі скла, кераміки та порцеляни, а також ізоляційних матеріалів. Завдяки своєму однорідному складу, що містить до 98 % оксиду кремнію (SiO2) та відмінним абсорбуючим властивостям кварцовий пісок також застосовується в якості фільтруючого матеріалу для очищення води

Посилання

- Gadyatov, V. G., Kiah, D. A., Zhidkova, S. A. (2010). In the case of the giant Quartz Peska in the resulting special pure quartz. News. Voronezh. Goss. UN-Ta. Ser. Geology, 2, 324–327.

- Vatalis, K. I., Charalambides, G., Benetis, N. P. (2015). Market of High Purity Quartz Innovative Applications. Procedia Economics and Finance, 24, 734–742. https://doi.org/10.1016/s2212-5671(15)00688-7

- Kurets, V. I., Solovyov, M. A., Zhuchkov, A. I., Barskaya, A. V. (2012). Electrical fracturing technologies for processing and destruction of materials. Study guide. Tomsk: TPU, 272.

- Andreev, S. E., Perov, V. A., Zverevich, V. V. (1980). Crushing, grinding and screening of minerals. Moscow: Nedra, 415.

- Yang, J., Zhu, P., Li, H., Li, Z., Huo, X., Ma, S. (2022). Research on the Relationship between Multi-Component Complex Ore and Its Component Minerals’ Grinding Characteristics under Abrasion Force. Minerals, 13 (1), 6. https://doi.org/10.3390/min13010006

- Korekina, M. A., Shtenberg, M. V., Lutoev, V. P., Shanina, S. N. (2020). Microelement composition of vein quartz of the Kuznechikhinskoe deposit (South Urals). Obogashchenie Rud, 23–29. https://doi.org/10.17580/or.2020.05.04

- Aliasgharzadeh-Polesangi, A., Abdollah-Pour, H., Farzin, Y. A. (2019). Nanostructured silicon production from quartzite ore by low-energy wet blending of the reagents, reduction in controlled atmosphere, and hydrometallurgy. Journal of Materials Research and Technology, 8 (1), 1014–1023. https://doi.org/10.1016/j.jmrt.2018.05.027

- Jiang, X., Chen, J., Wei, M., Li, F., Ban, B., Li, J. (2020). Effect of impurity content difference between quartz particles on flotation behavior and its mechanism. Powder Technology, 375, 504–512. https://doi.org/10.1016/j.powtec.2020.07.107

- Li, Y., Ma, Q., Xia, Z., Li, W., Lei, S. (2023). Influences of Na2CO3 roasting and H3PO4 hot-pressure leaching on the purification of vein quartz to achieve high-purity quartz. Hydrometallurgy, 218, 106065. https://doi.org/10.1016/j.hydromet.2023.106065

- Dal Martello, E., Bernardis, S., Larsen, R. B., Tranell, G., Di Sabatino, M., Arnberg, L. (2012). Electrical fragmentation as a novel route for the refinement of quartz raw materials for trace mineral impurities. Powder Technology, 224, 209–216. https://doi.org/10.1016/j.powtec.2012.02.055

- Potokin, A. S., Kolobov, V. V. (2022). Study of rocks from mining processing plants of the Murmansk region by use electric pulse disintegration materials method. Mining Industry Journal (Gornay Promishlennost), 5/2022, 135–138. https://doi.org/10.30686/1609-9192-2022-5-135-138

- Bulkairova, G., Nussupbekov, B., Bolatbekova, M., Khassenov, A., Nussupbekov, U., Karabekova, D. (2023). A research of the effect of an underwater electric explosion on the selectivity of destruction of quartz raw materials. Eastern-European Journal of Enterprise Technologies, 3 (12 (123)), 30–37. https://doi.org/10.15587/1729-4061.2023.279009

- Khassenov, A. K., Karabekova, D. Zh., Nussupbekov, B. R., Bulkairova, G. A., Kudusov, A. S., Alpysova, G. K., Bolatbekova, M. М. (2023). Investigation of the influences of pulsed electrical discharges on the grinding of quartz raw materials. Bulletin of the Karaganda University “Physics Series,” 110 (2), 93–99. https://doi.org/10.31489/2023ph2/93-99

- Kurytnik, I. P., Nussupbekov, B. R., Karabekova, D. Zh., Khassenov, A. K., Kazhikenova, A. Sh.(2018). Investigation of a crushing and grinding unit of an electropulseinstallation. Archives of Foundry Engineering, 18 (1), 61–64. https://doi.org/10.24425/118812

- Nusupbekov, B. R., Kussaiynov, K., Sakipova, S. E., Khassenov, А. K., Beisenbek, A. Zh. (2016). On Improvement of Technology of Complex Extraction of Rare and Trace Metals by Electropulse Method. Metallofizika I Noveishie Tekhnologii, 36 (2), 275–286. https://doi.org/10.15407/mfint.36.02.0275

- Yutkin, L. A. (1986). Elektrogidpavlicheskiy effekt i ego primenenie v promyshlennosti. Leningrad: Mashinostroenie, 253.

- Samilin, V., Biletsky, V. (2003). Special methods of mineral processing. Donetsk: Vostochny publishing house, 116.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Ayanbergen Khassenov, Gulden Bulkairova, Dana Karabekova, Madina Bolatbekova, Gulnur Alpyssova, Arystan Kudussov, Perizat Kissabekova

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.