Development of a method for calculating statistical characteristics of the input material flow of a transport conveyor

DOI:

https://doi.org/10.15587/1729-4061.2023.289931Keywords:

transport conveyor, similarity criteria, statistical characteristics, correlation function, material flow typificationAbstract

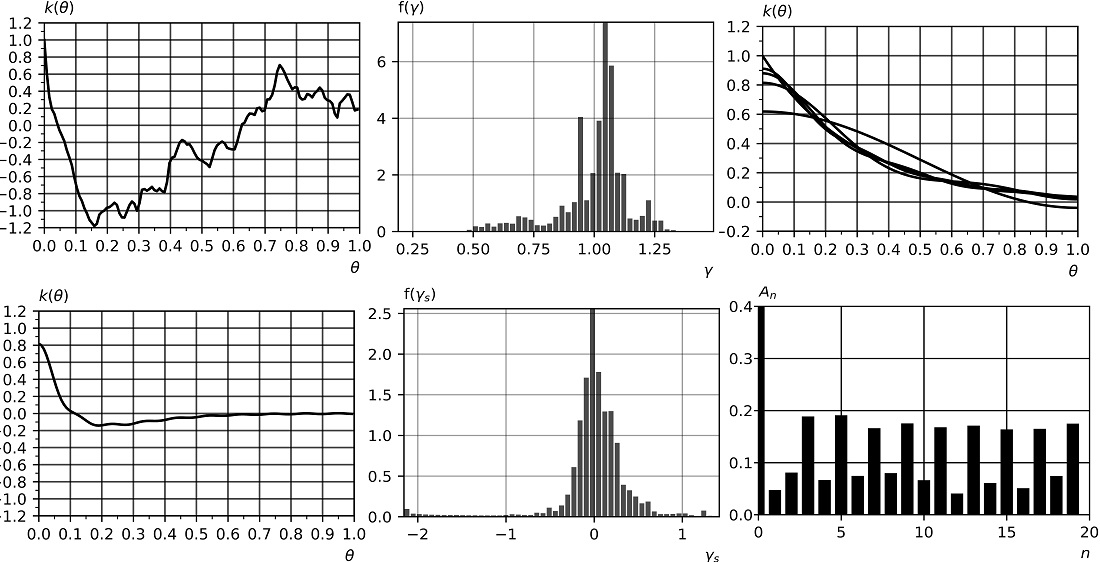

The object of this study is the material flow incoming the conveyor. The actual problem of calculating the stochastic characteristics of the input material flow of a transport system, based on the typification of the input material flow, is being solved. When constructing a model of the input material flow, methods of similarity theory were used. A criterion has developed for dividing the realization of the input material flow into a deterministic and stochastic component, which makes it possible to represent the stochastic component of the input flow in the form of an realization of a centered ergodic process. A method is presented for calculating amplitude and phase frequency spectra for the components of the input material flow, based on specified types of theoretical correlation functions. The calculating accuracy of the normalized correlation function values is e~0.05. Distinctive features of the obtained results are that the typification method of the input material flow is based on the use of the amplitude spectrum for the input material flow. A special feature of the results obtained is that a single realization of the input material flow was used to model the input material flow. The scope of application of the obtained results is the mining industry. The developed methodology for calculating the statistical characteristics of the input material flow allow to improve the accuracy of algorithms for optimal control of the flow parameters of the transport system for a mining enterprise. The condition for the practical application of the obtained results is the presence in the sections of the transport conveyor of measuring sensors that determine the speed of the belt and the amount of material in the bunker

References

- Siemens – innovative solutions for the mining industry. Available at: https://im-mining.com/advertiser_profile/siemens-innovative-solutions-mining-industry/

- Pihnastyi, O., Ivanovska, O. (2022). Improving the prediction quality for a multi-section transport conveyor model based on a neural network. Proceedings of International Scientific Conference Information Technology and Implementation, 3132, 24–38. Available at: http://ceur-ws.org/Vol-3132/Paper_3.pdf

- Bajda, M., Błażej, R., Jurdziak, L. (2019). Analysis of changes in the length of belt sections and the number of splices in the belt loops on conveyors in an underground mine. Engineering Failure Analysis, 101, 436–446. doi: https://doi.org/10.1016/j.engfailanal.2019.04.003

- Koman, M., Laska, Z. (2014). The constructional solution of conveyor system for reverse and bifurcation of the ore flow, Rudna mine KGHM Polska Miedź SA. CUPRUM, 3 (72), 69–82.

- Pihnastyi, O., Khodusov, V. (2020). Development of the controlling speed algorithm of the conveyor belt based on TOU-tariffs. Proceedings of the 2nd International Workshop on Information-Communication Technologies & Embedded Systems, 2762, 73–86. Available at: https://mpra.ub.uni-muenchen.de/104681/

- Halepoto, I. A., Shaikh, M. Z., Chowdhry, B. S., Uqaili, M. u hammad A. (2016). Design and Implementation of Intelligent Energy Efficient Conveyor System Model Based on Variable Speed Drive Control and Physical Modeling. International Journal of Control and Automation, 9 (6), 379–388. doi: https://doi.org/10.14257/ijca.2016.9.6.36

- He, D., Pang, Y., Lodewijks, G., Liu, X. (2018). Healthy speed control of belt conveyors on conveying bulk materials. Powder Technology, 327, 408–419. doi: https://doi.org/10.1016/j.powtec.2018.01.002

- Korniienko, V. I., Matsiuk, S. M., Udovyk, I. M. (2018). Adaptive optimal control system of ore large crushing process. Radio Electronics, Computer Science, Control, 1, 159–165. doi: https://doi.org/10.15588/1607-3274-2018-1-18

- Kiriia, R., Shyrin, L. (2019). Reducing the energy consumption of the conveyor transport system of mining enterprises. E3S Web of Conferences, 109, 00036. doi: https://doi.org/10.1051/e3sconf/201910900036

- Pihnastyi, O., Kozhevnikov, G., Khodusov, V. (2020). Conveyor Model with Input and Output Accumulating Bunker. 2020 IEEE 11th International Conference on Dependable Systems, Services and Technologies (DESSERT). doi: https://doi.org/10.1109/dessert50317.2020.9124996

- Kawalec, W., Król, R. (2021). Generating of Electric Energy by a Declined Overburden Conveyor in a Continuous Surface Mine. Energies, 14 (13), 4030. doi: https://doi.org/10.3390/en14134030

- Curtis, A., Sarc, R. (2021). Real-time monitoring of volume flow, mass flow and shredder power consumption in mixed solid waste processing. Waste Management, 131, 41–49. doi: https://doi.org/10.1016/j.wasman.2021.05.024

- Stadnik, N. (2012). Frequency-Controlled Electric Drive of Band Conveyors Based on Self-Ventilating Engines. Scientific Bulletin of the Donetsk National Technical University, 2, 226–232.

- Bhadani, K., Asbjörnsson, G., Hulthén, E., Hofling, K., Evertsson, M. (2021). Application of Optimization Method for Calibration and Maintenance of Power-Based Belt Scale. Minerals, 11 (4), 412. doi: https://doi.org/10.3390/min11040412

- Carvalho, R., Nascimento, R., D’Angelo, T., Delabrida, S., G. C. Bianchi, A., Oliveira, R. A. R. et al. (2020). A UAV-Based Framework for Semi-Automated Thermographic Inspection of Belt Conveyors in the Mining Industry. Sensors, 20 (8), 2243. doi: https://doi.org/10.3390/s20082243

- Vasić, M., Miloradović, N., Blagojević, M. (2021). Speed control of high power multiple drive belt conveyors. IMK-14 - Istrazivanje i Razvoj, 27 (1), 9–15. doi: https://doi.org/10.5937/imk2101009v

- Pihnastyi, O., Burduk, A. (2022). Analysis of a Dataset for Modeling a Transport Conveyor. Proceedings of the 2nd International Workshop on Information Technologies: Theoretical and Applied Problems (ITTAP 2022), 3309, 319–328. Available at: https://ceur-ws.org/Vol-3309/paper20.pdf

- Pihnastyi, O. M. (2018). Statistical theory of control systems of the flow production. LAP LAMBERT Academic Publishing, 436.

- Azarenkov, N., Pihnastyi, O., Khodusov, V. (2011). To the question of similarity of technological processes of production and technical systems. Reports of the National Academy of Sciences of Ukraine, 2, 29–35.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oleh Pihnastyi, Dmytro Kudii

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.