Розробка методa розрахунку статистичних характеристик вхідного потоку матеріалу транспортного конвеєра

DOI:

https://doi.org/10.15587/1729-4061.2023.289931Ключові слова:

транспортний конвеєр, критерії подібності, статистичні характеристики, функція кореляції, типізація потоку матеріалуАнотація

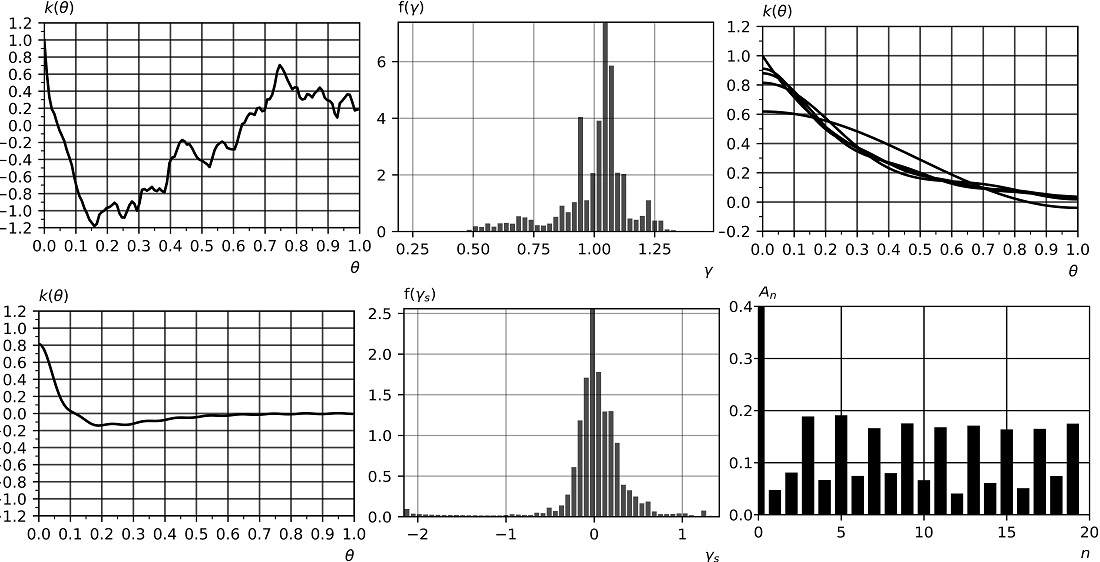

Об'єктом цього дослідження виступає потік матеріалу, що надходить на вхід транспортного конвеєра. Вирішується актуальна проблема розрахунку стохастичних характеристик вхідного потоку матеріалу транспортної системи, що базується на типізації вхідного потоку матеріалу. Під час побудови моделі вхідного потоку матеріалу використано методи теорії подібності. Реалізація для вхідного потоку матеріалу представлена суперпозицією детермінованої та стохастичної складової вхідного потоку матеріалу. Розроблено критерій поділу реалізації вхідного потоку матеріалу на детерміновану та стохастичну складову, що дозволяє уявити стохастичну складову вхідного потоку у вигляді реалізації центрованого ергодичного потоку матеріалу. Наведено методи розрахунку амплітудних та фазових частотних спектрів для складових вхідного потоку матеріалу, засновані на заданих типах теоретичної функції кореляції. Точність розрахунку значень нормованої функції кореляції становить e~0.05.

Відмінними рисами отриманих результатів є те, що метод типізації вхідного потоку матеріалу ґрунтується на використанні амплітудного спектра для вхідного потоку матеріалу. Особливістю отриманих результатів слід назвати те, що для моделювання вхідного потоку матеріалу використано єдину реалізацію вхідного потоку матеріалу.

Сферою застосування одержаних результатів є гірничодобувна промисловість. Розроблена методика розрахунку статистичних характеристик вхідного потоку матеріалу дозволить підвищити точність алгоритмів оптимального керування потоковими параметрами транспортної системи гірничодобувного підприємства. Умовою практичного використання отриманих результатів є наявність у секціях транспортного конвеєра вимірювальних датчиків, що визначають швидкість стрічки та кількість матеріалу в бункерах, що акумулюють

Посилання

- Siemens – innovative solutions for the mining industry. Available at: https://im-mining.com/advertiser_profile/siemens-innovative-solutions-mining-industry/

- Pihnastyi, O., Ivanovska, O. (2022). Improving the prediction quality for a multi-section transport conveyor model based on a neural network. Proceedings of International Scientific Conference Information Technology and Implementation, 3132, 24–38. Available at: http://ceur-ws.org/Vol-3132/Paper_3.pdf

- Bajda, M., Błażej, R., Jurdziak, L. (2019). Analysis of changes in the length of belt sections and the number of splices in the belt loops on conveyors in an underground mine. Engineering Failure Analysis, 101, 436–446. doi: https://doi.org/10.1016/j.engfailanal.2019.04.003

- Koman, M., Laska, Z. (2014). The constructional solution of conveyor system for reverse and bifurcation of the ore flow, Rudna mine KGHM Polska Miedź SA. CUPRUM, 3 (72), 69–82.

- Pihnastyi, O., Khodusov, V. (2020). Development of the controlling speed algorithm of the conveyor belt based on TOU-tariffs. Proceedings of the 2nd International Workshop on Information-Communication Technologies & Embedded Systems, 2762, 73–86. Available at: https://mpra.ub.uni-muenchen.de/104681/

- Halepoto, I. A., Shaikh, M. Z., Chowdhry, B. S., Uqaili, M. u hammad A. (2016). Design and Implementation of Intelligent Energy Efficient Conveyor System Model Based on Variable Speed Drive Control and Physical Modeling. International Journal of Control and Automation, 9 (6), 379–388. doi: https://doi.org/10.14257/ijca.2016.9.6.36

- He, D., Pang, Y., Lodewijks, G., Liu, X. (2018). Healthy speed control of belt conveyors on conveying bulk materials. Powder Technology, 327, 408–419. doi: https://doi.org/10.1016/j.powtec.2018.01.002

- Korniienko, V. I., Matsiuk, S. M., Udovyk, I. M. (2018). Adaptive optimal control system of ore large crushing process. Radio Electronics, Computer Science, Control, 1, 159–165. doi: https://doi.org/10.15588/1607-3274-2018-1-18

- Kiriia, R., Shyrin, L. (2019). Reducing the energy consumption of the conveyor transport system of mining enterprises. E3S Web of Conferences, 109, 00036. doi: https://doi.org/10.1051/e3sconf/201910900036

- Pihnastyi, O., Kozhevnikov, G., Khodusov, V. (2020). Conveyor Model with Input and Output Accumulating Bunker. 2020 IEEE 11th International Conference on Dependable Systems, Services and Technologies (DESSERT). doi: https://doi.org/10.1109/dessert50317.2020.9124996

- Kawalec, W., Król, R. (2021). Generating of Electric Energy by a Declined Overburden Conveyor in a Continuous Surface Mine. Energies, 14 (13), 4030. doi: https://doi.org/10.3390/en14134030

- Curtis, A., Sarc, R. (2021). Real-time monitoring of volume flow, mass flow and shredder power consumption in mixed solid waste processing. Waste Management, 131, 41–49. doi: https://doi.org/10.1016/j.wasman.2021.05.024

- Stadnik, N. (2012). Frequency-Controlled Electric Drive of Band Conveyors Based on Self-Ventilating Engines. Scientific Bulletin of the Donetsk National Technical University, 2, 226–232.

- Bhadani, K., Asbjörnsson, G., Hulthén, E., Hofling, K., Evertsson, M. (2021). Application of Optimization Method for Calibration and Maintenance of Power-Based Belt Scale. Minerals, 11 (4), 412. doi: https://doi.org/10.3390/min11040412

- Carvalho, R., Nascimento, R., D’Angelo, T., Delabrida, S., G. C. Bianchi, A., Oliveira, R. A. R. et al. (2020). A UAV-Based Framework for Semi-Automated Thermographic Inspection of Belt Conveyors in the Mining Industry. Sensors, 20 (8), 2243. doi: https://doi.org/10.3390/s20082243

- Vasić, M., Miloradović, N., Blagojević, M. (2021). Speed control of high power multiple drive belt conveyors. IMK-14 - Istrazivanje i Razvoj, 27 (1), 9–15. doi: https://doi.org/10.5937/imk2101009v

- Pihnastyi, O., Burduk, A. (2022). Analysis of a Dataset for Modeling a Transport Conveyor. Proceedings of the 2nd International Workshop on Information Technologies: Theoretical and Applied Problems (ITTAP 2022), 3309, 319–328. Available at: https://ceur-ws.org/Vol-3309/paper20.pdf

- Pihnastyi, O. M. (2018). Statistical theory of control systems of the flow production. LAP LAMBERT Academic Publishing, 436.

- Azarenkov, N., Pihnastyi, O., Khodusov, V. (2011). To the question of similarity of technological processes of production and technical systems. Reports of the National Academy of Sciences of Ukraine, 2, 29–35.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Oleh Pihnastyi, Dmytro Kudii

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.