Identifying some regularities of the heat transfer in the welded joint of SUS304 pipe using a numerical approach

DOI:

https://doi.org/10.15587/1729-4061.2023.290124Keywords:

heat transfer, SUS304, heat flux: welded joint, friction stir weldingAbstract

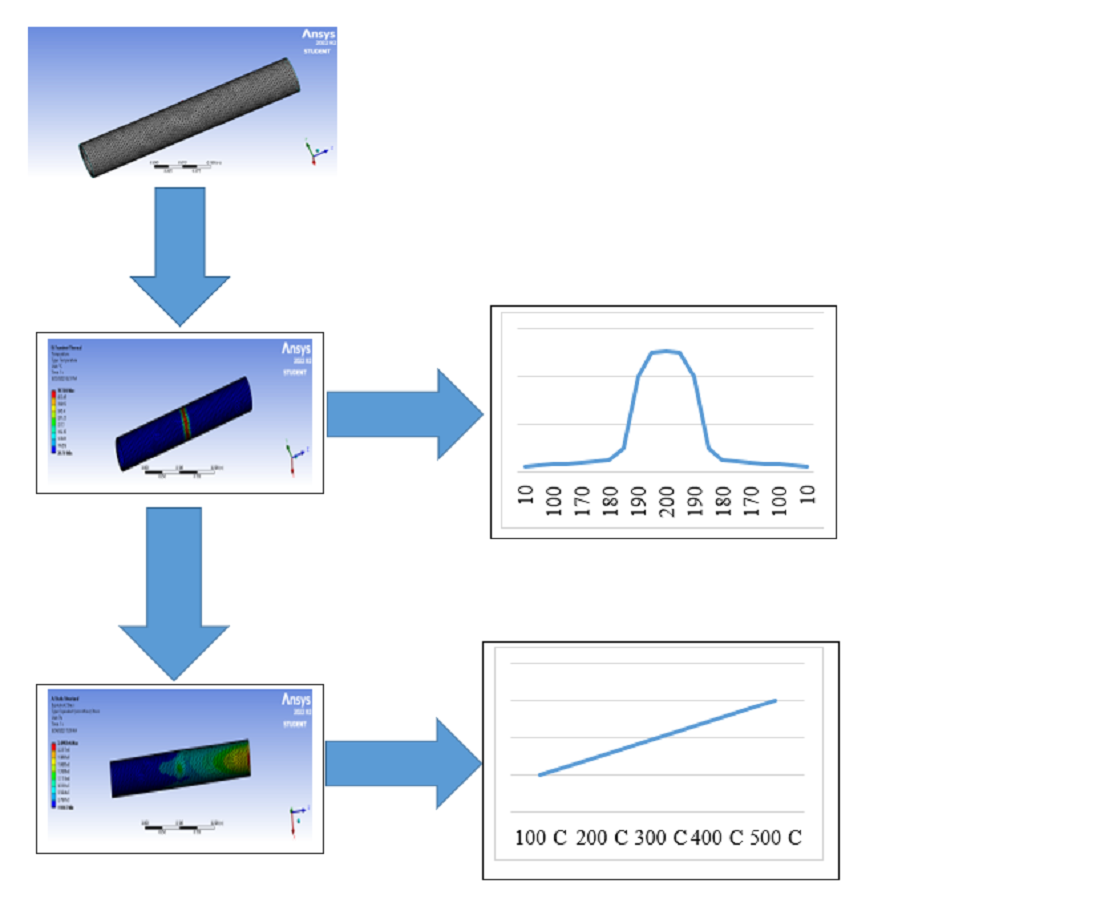

In this study, an investigation into the impact of heat transmission in the welded junction of SUS304 pipe has been carried out with the use of a numerical method. An investigation was carried out by employing ANSYS’s static structural tools in conjunction with the software package’s thermal transient analysis. Based on the heat flow on the welding point, where the temperature reaches 507 °C within 200 mm of the end of the welded pipe, an examination into the efficiency of heat transfer has been carried out. This analysis was based on the heat flow on the welding point. As the total heat flux approaches 7.02e6 W∙m–2, studies have been conducted on the topic. There have been three types of directional heat flux measurements made (X, Y, and Z), with the numerical findings indicating that the X direction produces the most variable heat flow readings. These checks were performed in a variety of settings. These were chosen as the correct paths to go since they led directly to the source of the warmth. whereas the Z-axis permits the minimum amount of heat flow throughout the board. The damaged area identified on the trees that were still standing was factored into the calculation. To calculate the amount of residual stress, the Von Mises stress was applied repeatedly during the whole procedure. This tactic ended up being employed. Due to the tension caused by the pipe’s increased bending radius, the piece of pipe located 200 mm from the pipe’s distal end is the most vulnerable. The value was calculated to be 2.49e6 Pa when the temperature was increased to 500 °C.

References

- Savin, V. V., Lebedeva, K. N., Herelovich, V. V., Savina, L. A., Chaika, V. A. (2020). Prospects for the use of u-shaped welded pipes of steel a316l heat transfer assortment in chemical engineering. IOP Conference Series: Materials Science and Engineering, 939 (1), 012069. doi: https://doi.org/10.1088/1757-899x/939/1/012069

- Yang, Z., Fang, Y., He, J. (2020). Numerical simulation of heat transfer and fluid flow during vacuum electron beam welding of 2219 aluminium girth joints. Vacuum, 175, 109256. doi: https://doi.org/10.1016/j.vacuum.2020.109256

- Ji, Y., Yuan, D., Hao, Y., Tian, Z., Lou, J., Wu, Y. (2022). Experimental study on heat transfer performance of high temperature heat pipe with large length-diameter ratio for heat utilization of concentrated solar energy. Applied Thermal Engineering, 215, 118918. doi: https://doi.org/10.1016/j.applthermaleng.2022.118918

- Peng, X., Xu, G., Zhou, A., Yang, Y., Ma, Z. (2020). An adaptive Bernstein-Bézier finite element method for heat transfer analysis in welding. Advances in Engineering Software, 148, 102855. doi: https://doi.org/10.1016/j.advengsoft.2020.102855

- Ham, J., Shin, Y., Cho, H. (2019). Theoretical investigation of the influence of pipe diameter and exit channel width in welded plate heat exchanger on heat exchanger performance. Heat and Mass Transfer, 56 (3), 759–771. doi: https://doi.org/10.1007/s00231-019-02733-8

- Sharaf, H. K., Salman, S., Abdulateef, M. H., Magizov, R. R., Troitskii, V. I., Mahmoud, Z. H. et al. (2021). Role of initial stored energy on hydrogen microalloying of ZrCoAl(Nb) bulk metallic glasses. Applied Physics A, 127 (1). doi: https://doi.org/10.1007/s00339-020-04191-0

- Yao, Y., Ding, J., Zhang, Y., Wang, W., Lu, J. (2023). Thermal and hydraulic optimization of supercritical CO2 pillow plate heat exchanger with ellipse weld spots in CSP system. International Communications in Heat and Mass Transfer, 143, 106739. doi: https://doi.org/10.1016/j.icheatmasstransfer.2023.106739

- Der, O., Alqahtani, A. A., Marengo, M., Bertola, V. (2021). Characterization of polypropylene pulsating heat stripes: Effects of orientation, heat transfer fluid, and loop geometry. Applied Thermal Engineering, 184, 116304. doi: https://doi.org/10.1016/j.applthermaleng.2020.116304

- Markushin, M. E., Galanskiy, S. A., Maksimov, I. S., Zolkin, A. L. (2023). Passive control of a temperature of continuous welded rail using loop heat pipes. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0162725

- Sharaf, H. K., Salman, S., Dindarloo, M. H., Kondrashchenko, V. I., Davidyants, A. A., Kuznetsov, S. V. (2021). The effects of the viscosity and density on the natural frequency of the cylindrical nanoshells conveying viscous fluid. The European Physical Journal Plus, 136 (1). doi: https://doi.org/10.1140/epjp/s13360-020-01026-y

- Liu, Y., Wang, P., Fang, H., Ma, N. (2021). Mitigation of residual stress and deformation induced by TIG welding in thin-walled pipes through external constraint. Journal of Materials Research and Technology, 15, 4636–4651. doi: https://doi.org/10.1016/j.jmrt.2021.10.035

- Zhao, J., Ji, Y., Yuan, D.-Z., Guo, Y.-X., Zhou, S.-W. (2022). Structural effect of internal composite wick on the anti-gravity heat transfer performance of a concentric annular high-temperature heat pipe. International Communications in Heat and Mass Transfer, 139, 106404. doi: https://doi.org/10.1016/j.icheatmasstransfer.2022.106404

- Sharaf, H. K., Ishak, M. R., Sapuan, S. M., Yidris, N. (2020). Conceptual design of the cross-arm for the application in the transmission towers by using TRIZ–morphological chart–ANP methods. Journal of Materials Research and Technology, 9 (4), 9182–9188. doi: https://doi.org/10.1016/j.jmrt.2020.05.129

- Abdullah, Y. M., Aziz, G. S., Sharaf, H. K. (2023). Simulate the Rheological Behaviour of the Solar Collector by Using Computational Fluid Dynamic Approach. CFD Letters, 15 (9), 175–182. doi: https://doi.org/10.37934/cfdl.15.9.175182

- Yu, J., Xin, Z., Zhang, R., Chen, Z., Li, Y., Zhou, W. (2022). Effect of spiral woven mesh liquid pumping action on the heat transfer performance of ultrathin vapour chamber. International Journal of Thermal Sciences, 182, 107799. doi: https://doi.org/10.1016/j.ijthermalsci.2022.107799

- Sharaf, H. K., Alyousif, S., Khalaf, N. J., Hussein, A. F., Abbas, M. K. (2022). Development of bracket for cross arm structure in transmission tower: Experimental and numerical analysis. New Materials, Compounds and Applications, 6 (3), 257–275. Available at: http://jomardpublishing.com/UploadFiles/Files/journals/NMCA/V6N3/SharafHS.pdf

- Liu, Y., Yu, Y., Wang, P., Fang, H., Ma, N. (2022). Analysis and mitigation of the bending deformation in girth-welded slender pipes with numerical modelling and experimental measurement. Journal of Manufacturing Processes, 78, 278–287. doi: https://doi.org/10.1016/j.jmapro.2022.04.023

- Sharaf, H. K., Ishak, M. R., Sapuan, S. M., Yidris, N., Fattahi, A. (2020). Experimental and numerical investigation of the mechanical behavior of full-scale wooden cross arm in the transmission towers in terms of load-deflection test. Journal of Materials Research and Technology, 9 (4), 7937–7946. doi: https://doi.org/10.1016/j.jmrt.2020.04.069

- Liu, Y., Wang, P., Fang, H., Ma, N. (2021). Characteristics of welding distortion and residual stresses in thin-walled pipes by solid-shell hybrid modelling and experimental verification. Journal of Manufacturing Processes, 69, 532–544. doi: https://doi.org/10.1016/j.jmapro.2021.08.014

- Almagsoosi, L., Abadi, M. T. E., Hasan, H. F., Sharaf, H. K. (2022). Effect of the Volatility of the Crypto Currency and Its Effect on the Market Returns. Industrial Engineering & Management Systems, 21 (2), 238–243. doi: https://doi.org/10.7232/iems.2022.21.2.238

- Al-Fahad, I. O. B., Sharaf, H. kadhim, Bachache, L. N., Bachache, N. K. (2023). Identifying the mechanism of the fatigue behavior of the composite shaft subjected to variable load. Eastern-European Journal of Enterprise Technologies, 3 (7 (123)), 37–44. doi: https://doi.org/10.15587/1729-4061.2023.283078

- Chen, G., Tang, Y., Wan, Z., Zhong, G., Tang, H., Zeng, J. (2019). Heat transfer characteristic of an ultra-thin flat plate heat pipe with surface-functional wicks for cooling electronics. International Communications in Heat and Mass Transfer, 100, 12–19. doi: https://doi.org/10.1016/j.icheatmasstransfer.2018.10.011

- Gharib, A. R., Biglari, F. R., Shafaie, M., Kokabi, A. H. (2019). Experimental and numerical investigation of fixture time on distortion of welded part. The International Journal of Advanced Manufacturing Technology, 104 (1-4), 1121–1131. doi: https://doi.org/10.1007/s00170-019-03874-0

- Kong, Y. S., Cheepu, M., Park, Y. W. (2020). Effect of Heating Time on Thermomechanical Behavior of Friction-Welded A105 Bar to A312 Pipe Joints. Transactions of the Indian Institute of Metals, 73 (6), 1433–1438. doi: https://doi.org/10.1007/s12666-020-01900-4

- Mikulionok, I. O. (2019). Classification of Means of Enhancement of Heat Transfer from the Outer Surface of Pipes (Survey of Patents). Chemical and Petroleum Engineering, 55 (5-6), 491–499. doi: https://doi.org/10.1007/s10556-019-00651-4

- Liu, R.-F., Wang, J.-C. (2022). Application of finite element method to effect of weld overlay residual stress on probability of piping failure. International Journal of Pressure Vessels and Piping, 200, 104812. doi: https://doi.org/10.1016/j.ijpvp.2022.104812

- Raheemah, S. H., Fadheel, K. I., Hassan, Q. H., Aned, A. M., Turki Al-Taie, A. A., Sharaf, H. K. (2021). Numerical Analysis of the Crack Inspections Using Hybrid Approach for the Application the Circular Cantilever Rods. Pertanika Journal of Science and Technology, 29 (2). doi: https://doi.org/10.47836/pjst.29.2.22

- Raheemah, S. H., Ashham, M. A., Salman, K. (2019). Numerical investigation on enhancement of heat transfer using rod inserts in single pipe heat exchanger. Journal of Mechanical Engineering and Sciences, 13 (4), 6112–6124. doi: https://doi.org/10.15282/jmes.13.4.2019.24.0480

- Asadi, P., Alimohammadi, S., Kohantorabi, O., Soleymani, A., Fazli, A. (2020). Numerical investigation on the effect of welding speed and heat input on the residual stress of multi-pass TIG welded stainless steel pipe. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 235 (6-7), 1007–1021. doi: https://doi.org/10.1177/0954405420981335

- Salman, S., Sharaf, H. K., Hussein, A. F., Khalaf, N. J., Abbas, M. K., Aned, A. M. et al. (2022). Optimization of raw material properties of natural starch by food glue based on dry heat method. Food Science and Technology, 42. doi: https://doi.org/10.1590/fst.78121

- Salman, K. h., Elsheikh, A. H., Ashham, M., Ali, M. K. A., Rashad, M., Haiou, Z. (2019). Effect of cutting parameters on surface residual stresses in dry turning of AISI 1035 alloy. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41 (8). doi: https://doi.org/10.1007/s40430-019-1846-0

- Arora, H., Mahaboob Basha, K., Naga Abhishek, D., Devesh, B. (2022). Welding simulation of circumferential weld joint using TIG welding process. Materials Today: Proceedings, 50, 923–929. doi: https://doi.org/10.1016/j.matpr.2021.06.315

- Lavrentieva, O. O., Arkhypov, I. O., Kuchma, O. I., Uchitel, A. D. (2020). Use of simulators together with virtual and augmented reality in the system of welders’ vocational training: past, present, and future. doi: https://doi.org/10.31812/123456789/3748

- Alyaseri, N. H. A., Salman, M. D., Maseer, R. W., Hussein, E. K., Subhi, K. A., Alwan, S. A. et al. (2023). Exploring the Modeling of Socio-Technical Systems in the Fields of Sport, Engineering and Economics. Revista iberoamericana de psicología del ejercicio y el deporte, 18 (3), 338–341. Available at: https://dialnet.unirioja.es/servlet/articulo?codigo=9087565

- Jawad, K. K., Alyaseri, N. H. A., Alwan, S. A., Hussein, E. K., Subhi, K. A., Sharaf, H. K. et al. (2023). Contingency in Engineering Problem Solving Understanding its Role and Implications: Focusing on the sports Machine. Revista iberoamericana de psicología del ejercicio y el deporte, 18 (3), 334–337. Available at: https://dialnet.unirioja.es/servlet/articulo?codigo=9087564

- Salman, M. D., Alwan, S. A., Alyaseri, N. H. A., Subhi, K. A., Hussein, E. K., Sharaf, H. K. et al. (2023). The Impact of Engineering Anxiety on Students: A Comprehensive Study In the fields of Sport, economics, and teaching methods. Revista iberoamericana de psicología del ejercicio y el deporte, 18 (3), 326–329. Available at: https://dialnet.unirioja.es/servlet/articulo?codigo=9087521

- Alwan, S. A., Jawad, K. K., Alyaseri, N. H. A., Subhi, K. A., Hussein, E. K., Aned, A. M. et al. (2023). The Psychological Effects of Perfectionism on Sport, economic and Engineering Students. Revista iberoamericana de psicología del ejercicio y el deporte, 18 (3), 330–333. Available at: https://dialnet.unirioja.es/servlet/articulo?codigo=9087522

- Al-Fahad, I. O. B., Hassan, A. D., Faisal, B. M., Sharaf, H. kadhim. (2023). Identification of regularities in the behavior of a glass fiber-reinforced polyester composite of the impact test based on ASTM D256 standard. Eastern-European Journal of Enterprise Technologies, 4 (7 (124)), 63–71. doi: https://doi.org/10.15587/1729-4061.2023.286541

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Abbas Naseer Hasein, Ashham Mohammed Aned, Mortadha Kareem A. Razzaq

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.