Determining features in the wear resistance characteristics of tribocompounds with a textured hole surface under conditions of boundary friction

DOI:

https://doi.org/10.15587/1729-4061.2023.291785Keywords:

wear resistance, coefficient of friction, textured surface, hole, boundary friction, regeneration of lubricating film, lubricant droplet, mathematical modelAbstract

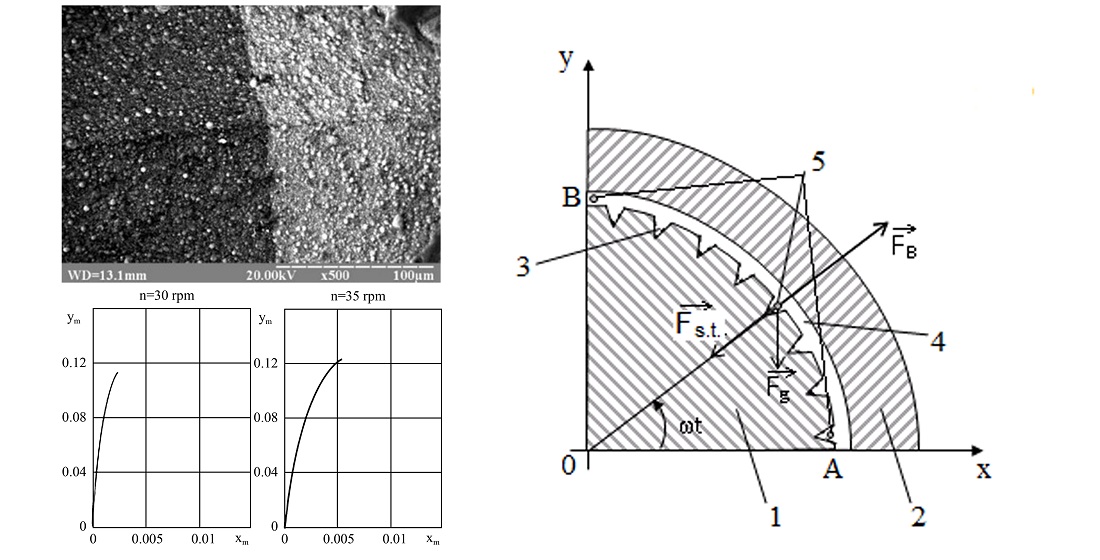

The influence of surface texture in the form of pits on the wear resistance of tribocompounds under conditions of limit friction was investigated. At the first stage of research, the mechanism of lubricant behavior between the contacting surfaces and inside the holes was modeled. The limiting condition of the rotation frequency of the sample (n>27) was established, under which a drop of lubricant "leaves" the hole in the upper position of the sample and remains in the space between the sample and the surface of the counterbody, ensuring the regeneration of the boundary lubricating film on the surface of the tribocontact when it is destroyed. When the rotation frequency of the sample is reduced (n<27), the lubricant droplet remains in the hole and does not affect the processes of the boundary lubricant film. At the second stage, experimental studies of tribocombinations with a textured hole surface under conditions of extreme friction were carried out. It was established that the high wear resistance of the textured hole surfaces is provided by the high protective effect of the texture, as well as the high efficiency of the marginal lubricating film. It has been proven that the strengthening of the surface texture by the method of ion-plasma thermocyclic nitriding additionally increases the wear resistance by 1.7 times due to the high protective effect of surface nitrided layers and their high hardness (up to 9500 MPa). This strengthens the effect of inhibiting the occurrence of defects in the surface layers of tribocontact, ensures a high rate of wetting of the places of actual contact of triboconnections, and speeds up the process of regeneration of the boundary lubricating film. Research results can be used to modify the surface layer of heavily loaded parts operating under extreme operating conditions with limited supply of lubricant under various types of friction and wear

References

- Ibatan, T., Uddin, M. S., Chowdhury, M. A. K. (2015). Recent development on surface texturing in enhancing tribological performance of bearing sliders. Surface and Coatings Technology, 272, 102–120. doi: https://doi.org/10.1016/j.surfcoat.2015.04.017

- Hamilton, D. B., Walowit, J. A., Allen, C. M. (1966). A Theory of Lubrication by Microirregularities. Journal of Basic Engineering, 88 (1), 177–185. doi: https://doi.org/10.1115/1.3645799

- Zhang, J., Meng, Y. (2012). Direct Observation of Cavitation Phenomenon and Hydrodynamic Lubrication Analysis of Textured Surfaces. Tribology Letters, 46 (2), 147–158. doi: https://doi.org/10.1007/s11249-012-9935-6

- Cupillard, S., Glavatskih, S., Cervantes, M. J. (2010). Inertia effects in textured hydrodynamic contacts. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 224 (8), 751–756. doi: https://doi.org/10.1243/13506501jet697

- Fowell, M., Olver, A. V., Gosman, A. D., Spikes, H. A., Pegg, I. (2006). Entrainment and Inlet Suction: Two Mechanisms of Hydrodynamic Lubrication in Textured Bearings. Journal of Tribology, 129 (2), 336–347. doi: https://doi.org/10.1115/1.2540089

- Filgueira Filho, I. C. M., Bottene, A. C., Silva, E. J., Nicoletti, R. (2021). Static behavior of plain journal bearings with textured journal - Experimental analysis. Tribology International, 159, 106970. doi: https://doi.org/10.1016/j.triboint.2021.106970

- Liu, W., Ni, H., Chen, H., Wang, P. (2019). Numerical simulation and experimental investigation on tribological performance of micro-dimples textured surface under hydrodynamic lubrication. International Journal of Mechanical Sciences, 163, 105095. doi: https://doi.org/10.1016/j.ijmecsci.2019.105095

- Etsion, I. (2004). Improving Tribological Performance of Mechanical Components by Laser Surface Texturing. Tribology Letters, 17 (4), 733–737. doi: https://doi.org/10.1007/s11249-004-8081-1

- Guo, Q., Zheng, L., Zhong, Y., Wang, S., Ren, L. (2022). Numerical simulation of hydrodynamic lubrication performance for continuous groove-textured surface. Tribology International, 167, 107411. doi: https://doi.org/10.1016/j.triboint.2021.107411

- Shen, Z., Wang, F., Chen, Z., Ruan, X., Zeng, H., Wang, J. et al. (2021). Numerical simulation of lubrication performance on chevron textured surface under hydrodynamic lubrication. Tribology International, 154, 106704. doi: https://doi.org/10.1016/j.triboint.2020.106704

- Shen, C., Khonsari, M. M. (2015). Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding. Tribology International, 82, 1–11. doi: https://doi.org/10.1016/j.triboint.2014.09.022

- Rom, M., Müller, S. (2018). An effective Navier-Stokes model for the simulation of textured surface lubrication. Tribology International, 124, 247–258. doi: https://doi.org/10.1016/j.triboint.2018.04.011

- Marchuk, V., Kindrachuk, M., Tisov, O., Kornienko, A., Radko, O., Kharchenko, V. (2019). Stress-strained state of textured surfaces with selectively indented regions. Functional Materials, 26 (4), 773–778. doi: https://doi.org/10.15407/fm26.04.773

- Tsyban’ov, G. V., Marchuk, V. E., Mikosyanchyk, O. O. (2019). Effect of Textured Dentated Surfaces on 30KhGSA Steel Damage and Life at Fatigue, Fretting Fatigue, and Fretting. Strength of Materials, 51 (3), 341–349. doi: https://doi.org/10.1007/s11223-019-00080-x

- Marchuk, V., Kindrachuk, M., Krysak, Ya., Tisov, O., Dukhota, O., Gradiskiy, Y. (2021). The Mathematical Model of Motion Trajectory of Wear Particle Between Textured Surfaces. Tribology in Industry, 43 (2), 241–246. doi: https://doi.org/10.24874/ti.1001.11.20.03

- Marchuk, V. Ye., Kindrachuk, M. V., Mirnenko, V. I., Mnatsakanov, R. G., Kornіenko, A. O., Bashta, O. V., Fedorchuk, S. V. (2019). Physical Interpretations of Internal Magnetic Field Influence on Processes in Tribocontact of Textured Dimple Surfaces. Journal of Nano- and Electronic Physics, 11 (5), 05013-1-05013–05015. doi: https://doi.org/10.21272/jnep.11(5).05013

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Volodymyr Marchuk, Myroslav Kindrachuk, Oleh Harmash, Volodymyr Kharchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.