Improving the technology of waxes obtaining from oil and fat waste

DOI:

https://doi.org/10.15587/1729-4061.2023.292182Keywords:

spent perlite, oil winterization waste, wax saponification value, filter powderAbstract

The object of the research is the extraction of waxes from the waste of the oil and fat industry – spent perlite.

As a result of oil winterization, a significant amount of spent filter powders is formed, the disposal of which poses a danger to the environment. At the same time, winterization waste contains a significant amount of oil and wax, which are important components of many types of products. Oil and wax extraction involves the use of volatile, fire-hazardous solvents. An urgent task is to develop new safe and effective technologies for obtaining oils and waxes from winterization waste.

The technology of extracting waxes from spent perlite, obtained as a result of winterization of sunflower oil, which involves treatment of perlite with sodium chloride solution, was investigated.

Perlite was used according to SOU 15.4-37-210:2004 (CAS Number 93763-70-3) with indicators: mass fraction of fat – 20.1 %, peroxide value – 19.5 ½ O mmol/kg, acid value – 3.5 mg KOH/g. The temperature of mass settling after treatment with sodium chloride is 20 °C, the duration – 10 hours.

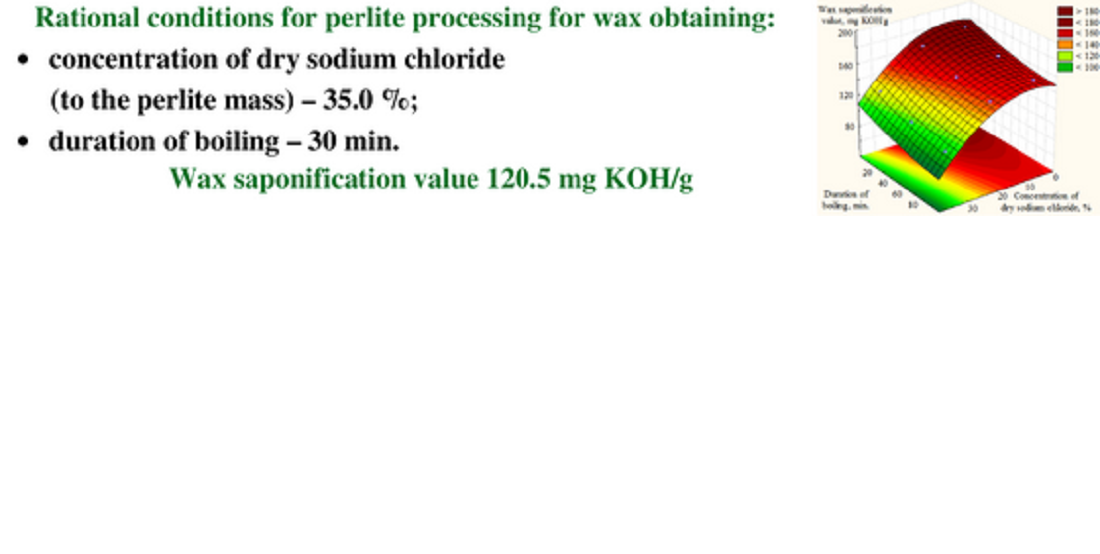

The following rational conditions for perlite processing using sodium chloride were determined: the concentration of dry sodium chloride (by weight of perlite) – 35.0 %, the duration of mass boiling – 30 minutes. Under these conditions, the experimental value of the saponification value of the obtained wax was 120.5 mg KOH/g. Wax quality indicators: melting point 71.5 °C, acid value 1.6 mg KOH/g, mass fraction of moisture 0.63 %.

The obtained results make it possible to obtain high-quality waxes from the waste of the oil and fat industry using a safe and affordable substance (sodium chloride). This will make it possible to avoid the need for waste disposal and increase the profitability of oil and fat enterprises due to obtaining valuable products from production waste

References

- Kovari, K., Denise, J., Hollo, J. (2006). Seed crushing, oil refining and environmental problem. Olaj. Szap. Kozmet, 45 (2), 45–52.

- Kachlishvili, I. N., Filippova, T. F. (2003). Experience in Manufacture of Hard Waxes. Combined Dewaxing and Deoiling Unit. Chemistry and Technology of Fuels and Oils, 39 (5), 233–239. doi: https://doi.org/10.1023/a:1026334207220

- Sytnik, N., Kunitsia, E., Mazaeva, V., Chernukha, A., Kovalov, P., Grigorenko, N. et al. (2020). Rational parameters of waxes obtaining from oil winterization waste. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 29–35. doi: https://doi.org/10.15587/1729-4061.2020.219602

- Modupalli, N., Thangaraju, S., Naik, G. M., Rawson, A., Natarajan, V. (2022). Assessment of physicochemical, functional, thermal, and phytochemical characteristics of refined rice bran wax. Food Chemistry, 396, 133737. doi: https://doi.org/10.1016/j.foodchem.2022.133737

- Fonseca, L. R., Santos, M. A. S., Santos, T. P., Cunha, R. L. (2023). Sunflower waxes as natural structuring agents to improve the technological properties of water-in-oil (W/O) high internal phase emulsions (HIPEs). Journal of Food Engineering, 357, 111638. doi: https://doi.org/10.1016/j.jfoodeng.2023.111638

- Simões, R., Miranda, I., Pereira, H. (2022). The Influence of Solvent and Extraction Time on Yield and Chemical Selectivity of Cuticular Waxes from Quercus suber Leaves. Processes, 10 (11), 2270. doi: https://doi.org/10.3390/pr10112270

- Hums, M. E., Moreau, R. A. (2019). A Simplified Method for Fractionation and Analysis of Waxes and Oils from Sorghum (Sorghum bicolor (L.) Moench) Bran. Journal of the American Oil Chemists’ Society, 96 (12), 1357–1366. doi: https://doi.org/10.1002/aocs.12284

- Redondas, C. E., Baümler, E. R., Carelli, A. A. (2019). Sunflower wax recovered from oil tank settlings: Revaluation of a waste product from the oilseed industry. Journal of the Science of Food and Agriculture, 100 (1), 201–211. doi: https://doi.org/10.1002/jsfa.10017

- Chalapud, M. C., Baümler, E. R., Carelli, A. A. (2016). Characterization of waxes and residual oil recovered from sunflower oil winterization waste. European Journal of Lipid Science and Technology, 119 (2). doi: https://doi.org/10.1002/ejlt.201500608

- Harron, A. F., Powell, M. J., Nunez, A., Moreau, R. A. (2017). Analysis of sorghum wax and carnauba wax by reversed phase liquid chromatography mass spectrometry. Industrial Crops and Products, 98, 116–129. doi: https://doi.org/10.1016/j.indcrop.2016.09.015

- Cascant, M. M., Breil, C., Garrigues, S., de la Guardia, M., Fabiano-Tixier, A. S., Chemat, F. (2017). A Green Analytical Chemistry Approach for Lipid Extraction: Computation Methods in the Selection of Green Solvents as Alternative to Hexane. Analytical and Bioanalytical Chemistry, 409, 3527–3539. doi: https://doi.org/10.1007/s00216-017-0323-9

- Ardenghi, N., Mulch, A., Pross, J., Maria Niedermeyer, E. (2017). Leaf wax n-alkane extraction: An optimised procedure. Organic Geochemistry, 113, 283–292. doi: https://doi.org/10.1016/j.orggeochem.2017.08.012

- Tuhanioglu, A., Mauromoustakos, A., Ubeyitogullari, A. (2023). Purifying waxes through selective extraction of triacylglycerols from a bioethanol production side-stream using supercritical carbon dioxide. The Journal of Supercritical Fluids, 202, 106059. doi: https://doi.org/10.1016/j.supflu.2023.106059

- Guan, M., Xu, X., Tang, X., Li, Y. (2022). Optimization of supercritical CO2 extraction by response surface methodology, composition analysis and economic evaluation of bamboo green wax. Journal of Cleaner Production, 330, 129906. doi: https://doi.org/10.1016/j.jclepro.2021.129906

- Al Bulushi, K., Attard, T. M., North, M., Hunt, A. J. (2018). Optimisation and economic evaluation of the supercritical carbon dioxide extraction of waxes from waste date palm (Phoenix dactylifera) leaves. Journal of Cleaner Production, 186, 988–996. doi: https://doi.org/10.1016/j.jclepro.2018.03.117

- Jana, S., Martini, S. (2016). Phase Behavior of Binary Blends of Four Different Waxes. Journal of the American Oil Chemists’ Society, 93 (4), 543–554. doi: https://doi.org/10.1007/s11746-016-2789-6

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Dmytro Saveliev, Olena Petrova, Pavlo Kovalov, Oleksandr Cherkashyn, Natalia Shevchuk, Nataliia Markova, Alla Ziuzko, Mykola Pidhorodetskyi, Anatolii Rozumenko, Oleksandr Ivashchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.