Identification of the effect of electric pulse discharges on the recycling of household glass

DOI:

https://doi.org/10.15587/1729-4061.2024.296855Keywords:

solid waste, electric pulse device, electric discharges, output of the finished productAbstract

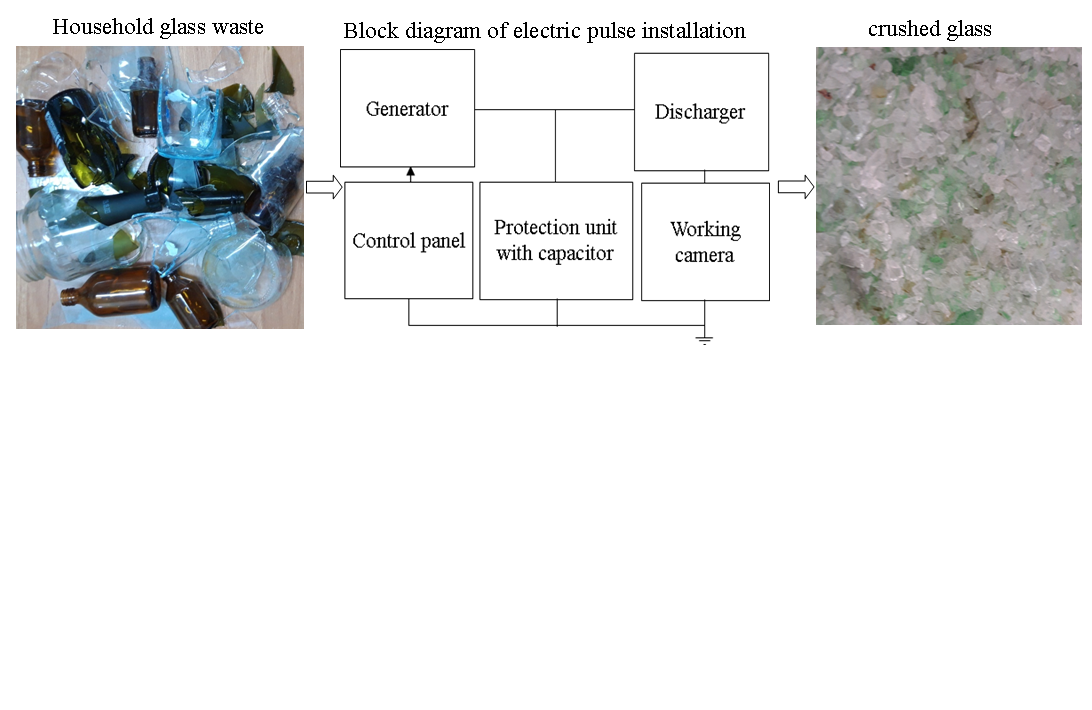

The work was devoted to the study of the recycling of household glass waste by the electric pulse method. Cullet and glass containers were considered as the object of research. Cullet and used glass containers are considered suitable for recycling among solid household waste.

The treatment of solid household waste was carried out with the formation of electrical discharges in an inhomogeneous environment (glass fragments and glass products in an aqueous environment). The experiments were carried out at different values of pulse discharge voltage (from 12 kV to 37 kV), capacitor bank capacity (from 0.4 to 1.2 µF), number of pulse discharges (from 250 to 1,000) and frequency (from 0.3 Hz to 2 Hz). The dependence of the output of the finished product on the parameters of electric pulse discharges has been revealed from the research results. According to the main results of the research work, it was found that as the parameters of electric pulse discharges increase, the yield of the finished product increases. The data made it possible to assign effective parameters for processing cullet and glass products using the electric pulse method. The granulometric composition of the powder material obtained by this method has been determined. A product with a diameter of the largest fraction of 5-8 mm and a diameter of a small fraction of 0.4 mm and 0.7 mm was obtained.

The results of the experiment can be used in research on saving natural resources, energy conservation and solving environmental problems of solid waste recycling. Powdered glass is used as a thermal insulator and decorative material in construction. In addition, crushed glass is used in the production of concrete as an additional raw material.

References

- Harrison, E., Berenjian, A., Seifan, M. (2020). Recycling of waste glass as aggregate in cement-based materials. Environmental Science and Ecotechnology, 4, 100064. https://doi.org/10.1016/j.ese.2020.100064

- Shakhova, V. N., Vitkalova, I. A., Torlova, A. S., Pikalov, E. S., Selivanov, O. G. (2019). Receiving of Ceramic Veneer with the Use of Unsorted Container Glass Breakage. Ecology and Industry of Russia, 23 (2), 36–41. https://doi.org/10.18412/1816-0395-2019-2-36-41

- Kurzhembaev, A. K., Beketova, G. K., Kazagachev, V. N. (2017). Analysis and assessment of the ecological state of the Republic of Kazakhstan. Technical Sciences: problems and prospects: materials of the V International Scientific Conference. Saint Petersburg: Its publishing house, 57–59.

- Vrijheid, M. (2000). Health Effects of Residence near Hazardous Waste Landfill Sites: A Review of Epidemiologic Literature. Environmental Health Perspectives, 108, 101. https://doi.org/10.2307/3454635

- Sun, L., Kim, M., Doh, J.-H., Zi, G. (2021). A Novel Method of Crushing Glass Aggregates to Reduce the Alkali-Silica Reaction. KSCE Journal of Civil Engineering, 25 (12), 4763–4770. https://doi.org/10.1007/s12205-021-2341-6

- Shelkovnikova, T., Baranov, E., Cherkasov, S., Pryazhenceva, E. (2019). Problems and prospects of collection and processing of battle glass and application of products on its basis. Bulletin of Belgorod State Technological University Named after. V. G. Shukhov, 9, 14–21. https://doi.org/10.34031/article_5da44ad180a513.69952350

- Lee, H., Lee, H. (2021). The Process Development of Glass Cullet and Recycled Glass Aggregate for Improving Recycling Rate. https://doi.org/10.21203/rs.3.rs-709571/v1

- Lambert, H., Corn, S., Léger, R., Ienny, P., Slangen, P., Fages, M. (2022). Ceramic Bonding Interface under Shear–Compression Stress: Ultra-High-Speed Imaging Contribution. Journal of Dental Research, 102 (3), 295–301. https://doi.org/10.1177/00220345221138500

- Dinh, H. L., Liu, J., Doh, J.-H., Ong, D. E. L. (2024). Influence of Si/Al molar ratio and ca content on the performance of fly ash-based geopolymer incorporating waste glass and GGBFS. Construction and Building Materials, 411, 134741. https://doi.org/10.1016/j.conbuildmat.2023.134741

- Korkosz, A., Ptaszynska, A., Hanel, A., Niewiadomski, M., Hupka, J. (2011). Cullet as filter medium for swimmig pool water treatment. Physicochemical Problems of Mineral Processing, 48 (1), 295–301. Available at: https://www.researchgate.net/publication/286447115

- Mazzi, A., Sciarrone, M., Bernardo, E. (2023). Environmental performance of glass foam as insulation material from waste glass with the alkali activation process. Heliyon, 9 (8), e19001. https://doi.org/10.1016/j.heliyon.2023.e19001

- Romero, M., Padilla, I., García Calvo, J. L., Carballosa, P., Pedrosa, F., López-Delgado, A. (2023). Development of Lightweight Mortars Using Sustainable Low-Density Glass Aggregates from Secondary Raw Materials. Materials, 16 (18), 6281. https://doi.org/10.3390/ma16186281

- Merga Tullu, A., Terfasa, T. T., Zerfe, E. A., Tadese, M., Beyene, E., Abebe, A. M., Adoshe, D. M. (2022). Effect of cullet on firing temperature and dielectric properties of porcelain insulator. Heliyon, 8 (2), e08922. https://doi.org/10.1016/j.heliyon.2022.e08922

- Iwaszko, J., Lubas, M., Sitarz, M., Zajemska, M., Nowak, A. (2021). Production of vitrified material from hazardous asbestos-cement waste and CRT glass cullet. Journal of Cleaner Production, 317, 128345. https://doi.org/10.1016/j.jclepro.2021.128345

- Dinh, H. L., Doh, J.-H., Liu, J., Lu, L., Song, H., Park, D. (2023). Comprehensive assessment of geopolymer concrete mechanical and environmental performance with glass cullet fine aggregates. Journal of Building Engineering, 76, 107094. https://doi.org/10.1016/j.jobe.2023.107094

- Bulkairova, G., Nussupbekov, B., Bolatbekova, M., Khassenov, A., Nussupbekov, U., Karabekova, D. (2023). A research of the effect of an underwater electric explosion on the selectivity of destruction of quartz raw materials. Eastern-European Journal of Enterprise Technologies, 3 (12 (123)), 30–37. https://doi.org/10.15587/1729-4061.2023.279009

- Kurytnik, I. P., Khassenov, A. K., Nussupbekov, U. B., Karabekova, D. Z., Nussupbekov, B. R., Bolatbekova, M. (2022). Development of a grinding device for producing coal powder-raw materials of coal-water fuel. Archive of Mechanical Engineering, 69 (2), 259–268. https://doi.org/10.24425/ame.2022.140414

- Nussupbekov, B., Khassenov, A., Nussupbekov, U., Akhmadiyev, B., Karabekova, D., Kutum, B., Tanasheva, N. (2022). Development of technology for obtaining coal-water fuel. Eastern-European Journal of Enterprise Technologies, 3 (8 (117)), 39–46. https://doi.org/10.15587/1729-4061.2022.259734

- Khassenov, A. K., Nussupbekov, B. R., Karabekova, D. Zh., Bulkairova, G. A., Shashubai, B. U., Bolatbekova, M. М. (2022). Electric pulse method of processing cullet. Bulletin of the Karaganda University “Physics Series,” 1 (105), 75–80. https://doi.org/10.31489/2022ph1/75-80

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ayanbergen Khassenov, Dana Karabekova, Madina Bolatbekova, Bekbolat Nussupbekov, Arystan Kudussov, Lyubov Chirkova, Perizat Kissabekova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.