Features of structural improvement of the cooking appliance for confectionery mass

DOI:

https://doi.org/10.15587/1729-4061.2024.297409Keywords:

mobile cooking device, increase of heat exchange surface, jam, resource efficiencyAbstract

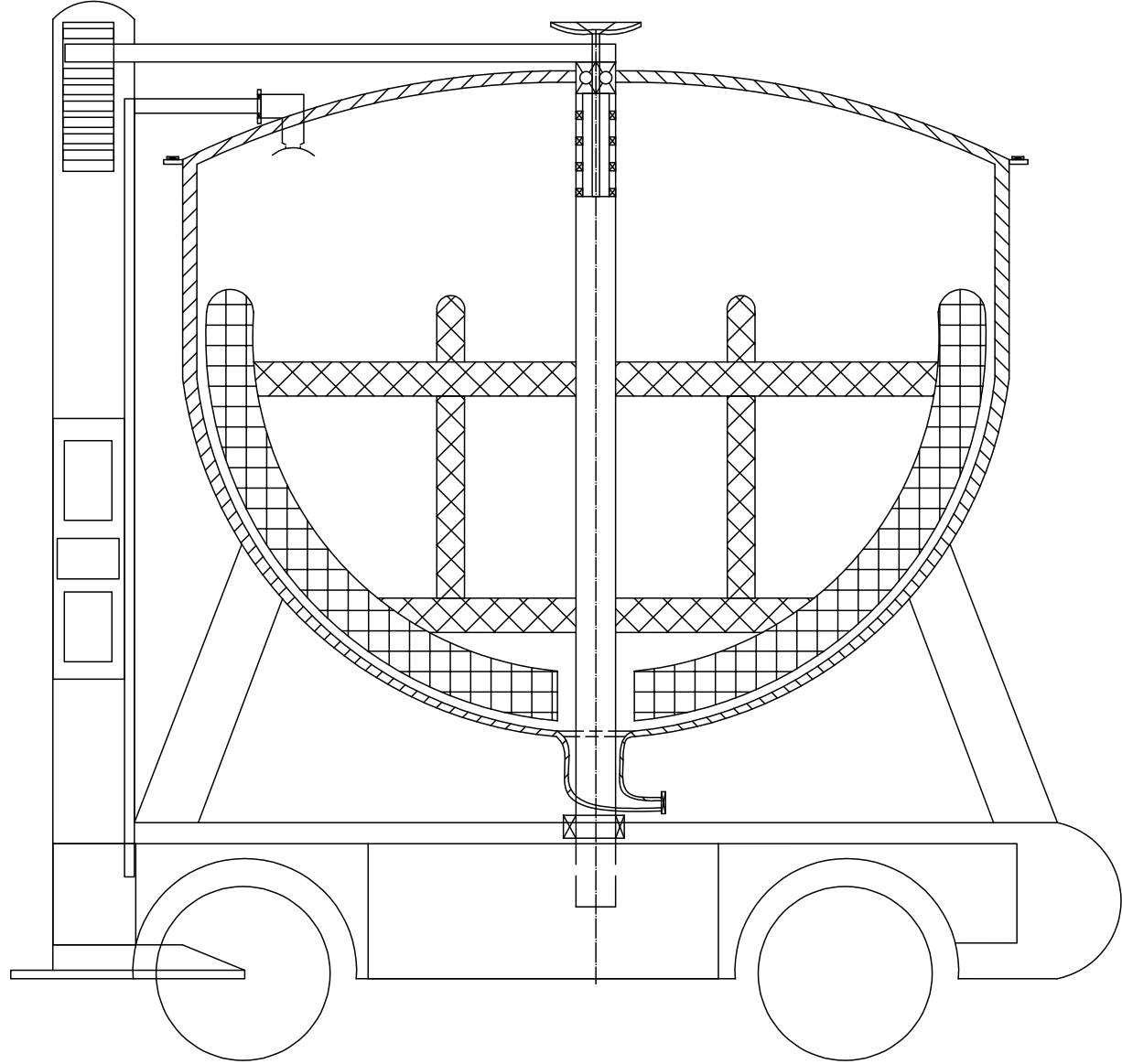

The object of this study is the process of making confectionery masses using the example of boiling the jam mass with the introduction of pre-dried fruit and berry raw materials, followed by boiling in a sugar syrup solution on an advanced cooking device. A feature of the improved cooking apparatus is the elimination of intermediate heat carriers, ensuring mobility, and increasing the heat exchange surface. Additional heating of the stirring device increases the total heat exchange surface by 0.23 m2. The elimination of the steam component made it possible to install the device on a moving platform, thereby ensuring its use in small confectionery workshops.

A method of jam production with the introduction of pre-dried fruit and berry raw materials and subsequent boiling in a sugar syrup solution is proposed. A feature is preliminary drying of raw materials in a vertical cylindrical IR dryer to 25...35 % SR at a temperature of 40...55 °С, grinding to 1.0...3.0 mm, with subsequent addition to sugar syrup. Boiling of the jam mass with the introduction of plant ingredients was carried out in the temperature range of 50...60 °С in the improved mobile design of the cooking apparatus to the content of 60...75 % SR, within 10...15 minutes. The set duration of output (620 s) to the stationary mode of cooking the jam mass at a temperature of 55 °С in the improved design of the cooking apparatus, which is 30 % less. The introduction of a stirrer design with a heating surface increases the usable heating surface by 0.23 m2, while the cooking time for jam, for example, is reduced by 26 %, and the specific heat consumption is reduced by 1.34 times. The use of an improved mobile device in the practical activities of enterprises of the industry will make it possible to reduce the time of cooking confectionery masses and improve operational indicators

References

- Misra, N. N., Koubaa, M., Roohinejad, S., Juliano, P., Alpas, H., Inácio, R. S. et al. (2017). Landmarks in the historical development of twenty first century food processing technologies. Food Research International, 97, 318–339. https://doi.org/10.1016/j.foodres.2017.05.001

- Chen, X., Gao, Z., McFadden, B. R. (2020). Reveal Preference Reversal in Consumer Preference for Sustainable Food Products. Food Quality and Preference, 79, 103754. https://doi.org/10.1016/j.foodqual.2019.103754

- Gunes, R., Palabiyik, I., Konar, N., Said Toker, O. (2022). Soft confectionery products: Quality parameters, interactions with processing and ingredients. Food Chemistry, 385, 132735. https://doi.org/10.1016/j.foodchem.2022.132735

- Zahorulko, A., Zagorulko, A., Savytska, N., Minenko, S., Pugach, A., Ponomarenko, N. et al. (2023). Design of a universal apparatus for heat treatment of meat and vegetable cooked and smoked products with the addition of dried semi-finished products of a high degree of readiness to the recipe. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 73–82. https://doi.org/10.15587/1729-4061.2023.285406

- Cadby, J., Araki, T. (2022). The recent rise of craft chocolate in Japan: A 2019 snapshot. Journal of Agriculture and Food Research, 7, 100273. https://doi.org/10.1016/j.jafr.2022.100273

- Zahorulko, A., Zagorulko, A., Yancheva, M., Savinok, O., Yakovets, L., Zhelievа, T. et al. (2023). Improving the production technique of meat chopped semi-finished products with the addition of dried semi-finished product with a high degree of readiness. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 6–14. https://doi.org/10.15587/1729-4061.2023.276249

- O’Shea, N., Ktenioudaki, A., Smyth, T. P., McLoughlin, P., Doran, L., Auty, M. A. E. et al. (2015). Physicochemical assessment of two fruit by-products as functional ingredients: Apple and orange pomace. Journal of Food Engineering, 153, 89–95. https://doi.org/10.1016/j.jfoodeng.2014.12.014

- Habanova, M., Saraiva, J. A., Holovicova, M., Moreira, S. A., Fidalgo, L. G., Haban, M. et al. (2019). Effect of berries/apple mixed juice consumption on the positive modulation of human lipid profile. Journal of Functional Foods, 60, 103417. https://doi.org/10.1016/j.jff.2019.103417

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chuiko, L., Yakovets, L., Pugach, A. et al. (2022). Improving the production technology of functional paste-like fruit-and-berry semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 43–52. https://doi.org/10.15587/1729-4061.2022.262924

- Nishiyama-Hortense, Y. P. de O., Rossi, M. J. de P., Shimizu-Marin, V. D., Janzantti, N. S., Gómez-Alonso, S., Da-Silva, R., Lago-Vanzela, E. S. (2022). Jelly candy enriched with BRS Violeta grape juice: Anthocyanin retention and sensory evaluation. Future Foods, 6, 100179. https://doi.org/10.1016/j.fufo.2022.100179

- Zagorulko, A., Shydakova-Kameniuka, O., Kasabova, K., Zahorulko, A., Budnyk, N., Kholobtseva, I. et al. (2023). Substantiating the technology of cream-whipped candy masses with the addition of berry and fruit paste. Eastern-European Journal of Enterprise Technologies, 3 (11 (123)), 50–59. https://doi.org/10.15587/1729-4061.2023.279287

- Adsare, S. R., Bellary, A. N., Sowbhagya, H. B., Baskaran, R., Prakash, M., Rastogi, N. K. (2016). Osmotic treatment for the impregnation of anthocyanin in candies from Indian gooseberry (Emblica officinalis). Journal of Food Engineering, 175, 24–32. https://doi.org/10.1016/j.jfoodeng.2015.11.023

- Kasabova, K., Samokhvalova, O., Zagorulko, A., Zahorulko, A., Babaiev, S., Bereza, O. et al. (2022). Improvement of Turkish delight production technology using a developed multi-component fruit and vegetable paste. Eastern-European Journal of Enterprise Technologies, 6 (11 (120)), 51–59. https://doi.org/10.15587/1729-4061.2022.269393

- Romo-Zamarrón, K. F., Pérez-Cabrera, L. E., Tecante, A. (2019). Physicochemical and Sensory Properties of Gummy Candies Enriched with Pineapple and Papaya Peel Powders. Food and Nutrition Sciences, 10 (11), 1300–1312. https://doi.org/10.4236/fns.2019.1011094

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- Borchani, M., Masmoudi, M., Ben Amira, A., Abbès, F., Yaich, H., Besbes, S. et al. (2019). Effect of enzymatic treatment and concentration method on chemical, rheological, microstructure and thermal properties of prickly pear syrup. LWT, 113, 108314. https://doi.org/10.1016/j.lwt.2019.108314

- Zahorulko, A., Zagorulko, A., Cherevko, O., Dromenko, O., Solomon, A., Yakobchuk, R. et al. (2021). Determination of the heat transfer coefficient of a rotary film evaporator with a heating film-forming element. Eastern-European Journal of Enterprise Technologies, 6 (8 (114)), 41–47. https://doi.org/10.15587/1729-4061.2021.247283

- Waseem, M., Tahir, A. U., Majeed, Y. (2023). Printing the future of food: The physics perspective on 3D food printing. Food Physics, 1, 100003. https://doi.org/10.1016/j.foodp.2023.100003

- Minenko, S., Cherevko, O., Skrynnik, V., Tesliuk, H., Bondar, M., Skoromna, O. et al. (2023). Improvement of the vacuum evaporator for the production of paste-like semi-finished products with a high degree of readiness. Eastern-European Journal of Enterprise Technologies, 5 (11 (125)), 76–83. https://doi.org/10.15587/1729-4061.2023.288896

- Winkler, A. (2014). Coffee, Cocoa and Derived Products (e.g. Chocolate). Food Safety Management, 251–282. https://doi.org/10.1016/b978-0-12-381504-0.00010-x

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. https://doi.org/10.15587/1729-4061.2022.254873

- Tehnicheskoe predstavlenie v konditerskoy promyshlennosti. Available at: https://baker-group.net/technology-and-recipes/confectionery/technical-performance-in-the-confectionery-industry.html

- Zahorulko, A. M., Zahorulko, O. Ye. (2016). Pat. No. 108041 UA. Hnuchkyi plivkovyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. No. u201600827; declareted: 02.02.2016; published: 24.06.2016, Bul. No. 12. Available at: https://repo.btu.kharkov.ua/handle/123456789/15246

- Zahorulko, A., Zagorulko, A., Yancheva, M., Dromenko, O., Sashnova, M., Petrova, K. et al. (2020). Improvement of the continuous "pipe in pipe" pasteurization unit. Eastern-European Journal of Enterprise Technologies, 4 (11 (106)), 70–75. https://doi.org/10.15587/1729-4061.2020.208990

- Tiefenbacher, K. F. (2017). Adjuncts—Filling Creams, Inclusions, Cacao and Chocolate. Wafer and Waffle, 313–404. https://doi.org/10.1016/b978-0-12-809438-9.00005-3

- Sashnova, M., Zahorulko, A., Savchenko, T., Gakhovich, S., Parkhomenko, I., Pankov, D. (2020). Improving the quality of the technological process of packaging shape formation based on the information structure of an automated system. Eastern-European Journal of Enterprise Technologies, 3 (2 (105)), 28–36. https://doi.org/10.15587/1729-4061.2020.205226

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anatolii Kobets, Andrii Puhach, Iryna Volovyk, Vira Puhach

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.