Improving the technology of oxidative stabilization of rapeseed oil

DOI:

https://doi.org/10.15587/1729-4061.2024.298432Keywords:

rapeseed oil, free radical oxidation process, induction period, oxidative stabilization technologyAbstract

The object of the research is the oxidation process of rapeseed oil.

Rapeseed oil is used for technical purposes, in the chemical and food industries, in particular, in the production of ecological fuel. Vegetable oils are subjected to oxidative deterioration processes, which are intensified under the conditions of access to oxygen, elevated temperatures, etc. Oxidation products worsen the technological properties and complicate the use of oils in chemical reactions. An important task is to improve the technology of oxidative stabilization of rapeseed oil, which is of great industrial importance.

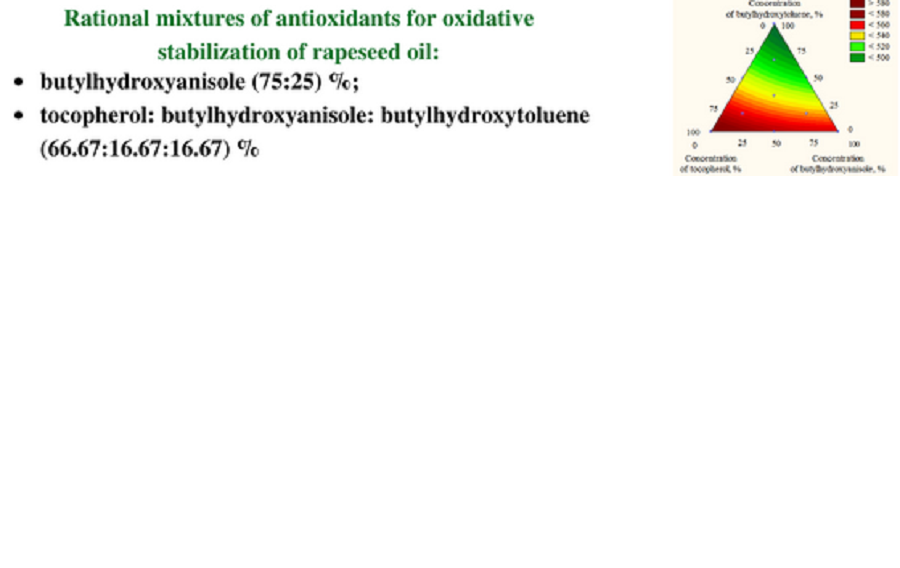

The oxidation process of refined deodorized rapeseed oil according to DSTU 8175 (CAS Number 120962-03-0) at a temperature of 110 °C was studied by the method of differential scanning calorimetry. The influence of different ratios of antioxidants (tocopherol, butylhydroxyanisole and butylhydroxytoluene) in the mixture on the oil induction period was determined. The total concentration of the antioxidant mixture in each experiment was 0.02 %. The induction period of the initial oil is 408.48 min. The rational ratios of the components of the antioxidant mixture were determined: tocopherol: butylhydroxyanisole (75:25) %; tocopherol: butylhydroxyanisole: butylhydroxytoluene (66.67:16.67:16.67) %. The corresponding oil induction periods were 579.75 min. and 561.55 min.

The physico-chemical indicators of rapeseed oil after 12 months of storage at a temperature of (20±2) °C in its original form and with the addition of the developed antioxidant mixtures were determined. The peroxide value of the oil was 12.5, 4.59, 6.45 ½ O mmol/kg, respectively.

The research results allow improving the technology of oxidative stabilization of rapeseed oil at elevated and standard temperatures. This will help to extend the oil shelf life, more efficiently and rationally use the oil in various areas

References

- Gupta, R., McRoberts, R., Yu, Z., Smith, C., Sloan, W., You, S. (2022). Life cycle assessment of biodiesel production from rapeseed oil: Influence of process parameters and scale. Bioresource Technology, 360, 127532. https://doi.org/10.1016/j.biortech.2022.127532

- Chew, S. C. (2020). Cold-pressed rapeseed (Brassica napus) oil: Chemistry and functionality. Food Research International, 131, 108997. https://doi.org/10.1016/j.foodres.2020.108997

- Korchak, M., Bliznjuk, O., Nekrasov, S., Gavrish, T., Petrova, O., Shevchuk, N. et al. (2022). Development of rational technology for sodium glyceroxide obtaining. Eastern-European Journal of Enterprise Technologies, 5 (6 (119)), 15–21. https://doi.org/10.15587/1729-4061.2022.265087

- Korchak, M., Bragin, O., Petrova, O., Shevchuk, N., Strikha, L., Stankevych, S. et al. (2022). Development of transesterification model for safe technology of chemical modification of oxidized fats. Eastern-European Journal of Enterprise Technologies, 6 (6 (120)), 14–19. https://doi.org/10.15587/1729-4061.2022.266931

- Gaide, I., Makareviciene, V., Sendzikiene, E., Gumbyte, M. (2022). Application of dolomite as solid base catalyst for transesterification of rapeseed oil with butanol. Sustainable Energy Technologies and Assessments, 52, 102278. https://doi.org/10.1016/j.seta.2022.102278

- Wang, M., Wang, M., Huyan, Z., Li, Q., Hu, K., Li, J., Yu, X. (2022). Investigation of the effects of lights, temperatures and packaging materials on the virgin rapeseed oil flavors during storage. LWT, 157, 113089. https://doi.org/10.1016/j.lwt.2022.113089

- de Jesus, J. H. F., Ferreira, A. P. G., Szilágyi, I. M., Cavalheiro, E. T. G. (2020). Thermal behavior and polymorphism of the antioxidants: BHA, BHT and TBHQ. Fuel, 278, 118298. https://doi.org/10.1016/j.fuel.2020.118298

- Wroniak, M., Rękas, A., Siger, A., Janowicz, M. (2016). Microwave pretreatment effects on the changes in seeds microstructure, chemical composition and oxidative stability of rapeseed oil. LWT - Food Science and Technology, 68, 634–641. https://doi.org/10.1016/j.lwt.2016.01.013

- Bär, F., Hopf, H., Knorr, M., Krahl, J. (2018). Rancimat and PetroOxy oxidation stability measurements of rapeseed oil methyl ester stabilized with hydrazides and antioxidants. Fuel, 232, 108–113. https://doi.org/10.1016/j.fuel.2018.05.095

- Yan, B., Meng, L., Huang, J., Liu, R., Zhang, N., Jiao, X. et al. (2023). Changes in oxidative stability of rapeseed oils under microwave irradiation: The crucial role of polar bioactive components. LWT, 185, 115100. https://doi.org/10.1016/j.lwt.2023.115100

- Szydłowska-Czerniak, A., Rabiej, D., Kyselka, J., Dragoun, M., Filip, V. (2018). Antioxidative effect of phenolic acids octyl esters on rapeseed oil stability. LWT, 96, 193–198. https://doi.org/10.1016/j.lwt.2018.05.033

- Mikołajczak, N., Tańska, M., Konopka, I. (2019). Impact of the addition of 4-vinyl-derivatives of ferulic and sinapic acids on retention of fatty acids and terpenoids in cold-pressed rapeseed and flaxseed oils during the induction period of oxidation. Food Chemistry, 278, 119–126. https://doi.org/10.1016/j.foodchem.2018.11.001

- Cisneros-Yupanqui, M., Chalova, V. I., Kalaydzhiev, H. R., Mihaylova, D., Krastanov, A. I., Lante, A. (2023). Ultrasound-assisted extraction of antioxidant bioactive compounds from wastes of rapeseed industry and their application in delaying rapeseed oil oxidation. Environmental Technology & Innovation, 30, 103081. https://doi.org/10.1016/j.eti.2023.103081

- Liu, Y.-Q., Song, Q.-W., Mo, C.-R., Yu, W.-W., Hu, C.-Y. (2023). Effect of neutralization treatment on properties of chitosan/bamboo leaf flavonoids/nano-metal oxide composite films and application of films in antioxidation of rapeseed oil. International Journal of Biological Macromolecules, 242, 124951. https://doi.org/10.1016/j.ijbiomac.2023.124951

- Jia, C., Li, J., Zhang, M., Ma, W., Zhao, S., Liu, R. et al. (2021). Antioxidant properties of the extracts of vine tea (Ampelopsis grossedentata) with the different color characteristics and inhibition of rapeseed and sunflower oil oxidation. LWT, 136, 110292. https://doi.org/10.1016/j.lwt.2020.110292

- Aladedunye, F., Matthäus, B. (2014). Phenolic extracts from Sorbus aucuparia (L.) and Malus baccata (L.) berries: Antioxidant activity and performance in rapeseed oil during frying and storage. Food Chemistry, 159, 273–281. https://doi.org/10.1016/j.foodchem.2014.02.139

- Kowalski, R., Kowalska, G., Pankiewicz, U., Mazurek, A., Włodarczyk-Stasiak, M., Sujka, M., Wyrostek, J. (2019). The effect of an addition of marjoram oil on stabilization fatty acids profile of rapeseed oil. LWT, 109, 225–232. https://doi.org/10.1016/j.lwt.2019.04.016

- Zhang, H., Gao, P., Fang, H., Zou, M., Yin, J., Zhong, W. et al. (2023). High-oleic rapeseed oil quality indicators and endogenous antioxidant substances under different processing methods. Food Chemistry: X, 19, 100804. https://doi.org/10.1016/j.fochx.2023.100804

- Rokosik, E., Siger, A., Rudzińska, M., Dwiecki, K. (2020). Antioxidant activity and synergism of canolol and α-tocopherol in rapeseed oil is affected by the presence of phospholipid association colloids. LWT, 133, 110095. https://doi.org/10.1016/j.lwt.2020.110095

- Toorani, M. R., Golmakani, M.-T., Gahruie, H. H. (2020). Antioxidant activity and inhibitory mechanism of γ-oryzanol as influenced by the unsaturation degree of lipid systems. LWT, 133, 109930. https://doi.org/10.1016/j.lwt.2020.109930

- Sytnik, N., Korchak, M., Nekrasov, S., Herasymenko, V., Mylostyvyi, R., Ovsiannikova, T. et al. (2023). Increasing the oxidative stability of linseed oil. Eastern-European Journal of Enterprise Technologies, 4 (6 (124)), 35–44. https://doi.org/10.15587/1729-4061.2023.284314

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Nataliia Staroselska, Mykola Korchak, Tetiana Ovsiannikova, Tetiana Falalieieva, Oleksandr Ternovyi, Valerii Krainov, Valentyna Mohutova, Liubov Morozova, Roman Chudak, Roman Mylostyvyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.