Determining the thermally-stressed state of motor-driven bowls for transporting liquid slag

DOI:

https://doi.org/10.15587/1729-4061.2024.299180Keywords:

slag bowl, blast furnace slag, thermal stresses, temperature, bowl thermal resistanceAbstract

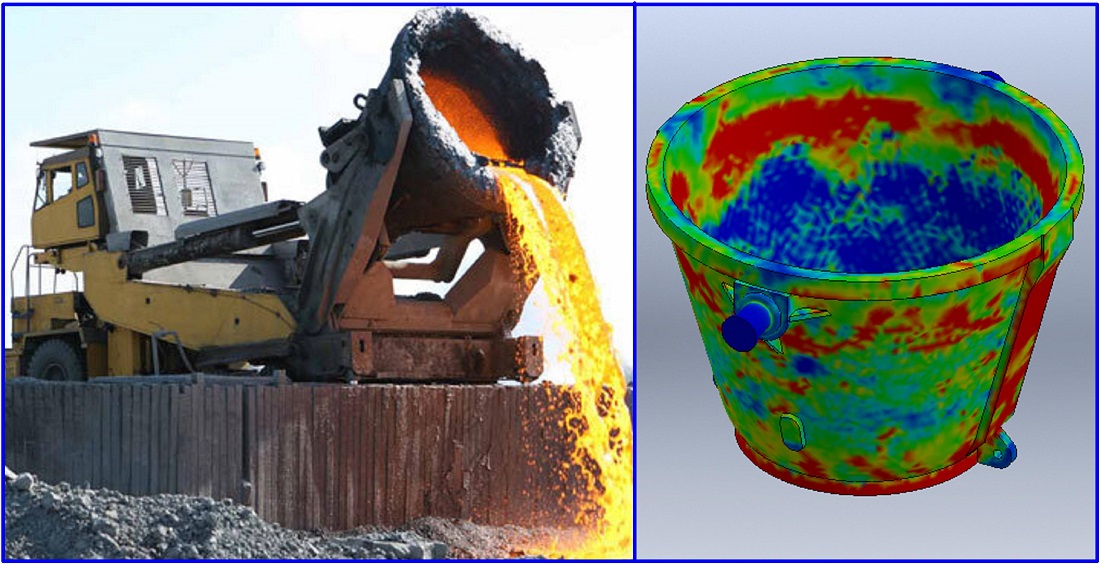

Slag bowls were chosen as the object of research, as important components of blast furnace, steelmaking, and ferroalloy shops of metallurgical enterprises. The main problem of operation of any slag trucks is their limited durability and frequent destruction of slag bowls. The reason for these problems is changes in the shape of the bowls during operation, manifested in the formation of narrowing places in the area of the support ring – for rail-mounted bowls, destruction of supporting pins – for rail-mounted slag trucks, or cracks in the walls. Those defects appear as a result of cyclic thermal effects of liquid slag on the bowl. Based on the results of computer simulation, it was established that the main role in the destruction of the support pins of motor-driven slag bowls belongs to temperature changes. The temperature stresses arising in the bowl are localized in the area of the slag mirror (200–250 MPa for 25L steel, 280–350 MPa for 30HML steel). The results provide grounds for improving the presented slag bowl to reduce temperature stresses in its walls and structures of the supporting trunnions. The results reported here are explained by the fact that with uneven heating of elastic bodies, temperature stresses appear, which, under certain configurations of temperature loads, lead to the destruction of structures. The findings from these studies are recommended to be used at enterprises for the design and manufacture of slag bowls, as information on the localization of dangerous places of the structure. In addition, the data presented here could be useful for metallurgical enterprises for detailed technical diagnosis of bowls in their dangerous places

References

- Nabarro, F. R. N. (1981). The calculation of thermal stresses in cylinders. International Journal of Engineering Science, 19 (12), 1651–1656. https://doi.org/10.1016/0020-7225(81)90157-9

- Ivanchenko, I. F. (1977). Issledovanie opytnogo obraztsa shlakovoza s chashey emkost'yu 24 m3. Otchet po NIR DMetI Otchet o NIR (zaklyuchitel'niy)/DMetI i DZMO. Dnepropetrovsk, 148.

- Lee, J., Hwang, K.-Y. (1996). Prediction of thermal stresses during vertical solidification of a pure metal with density change. Journal of Materials Processing Technology, 57 (1-2), 85–94. https://doi.org/10.1016/0924-0136(95)02065-9

- Wang, L., Chen, L., Yuan, F., Zhao, L., Li, Y., Ma, J. (2023). Thermal Stress Analysis of Blast Furnace Hearth with Typical Erosion Based on Thermal Fluid-Solid Coupling. Processes, 11 (2), 531. https://doi.org/10.3390/pr11020531

- Emelin, M. V., Rahmanov, S. R. (2009). K voprosu otsenki termonapryazhennogo sostoyaniya i termoprochnosti chash shlakovozov. Metallurgicheskaya i gornorudnaya promyshlennost', 2, 105–107. Available at: https://www.metaljournal.com.ua/mgp-02-2009/

- Rassokhin, D. O., Chigarev, V. V., Loza, V. A., Shishkin, V. V. (2014). Research of strain in the slag cars walls. Reporter of the Priazovskyi State Technical University. Section: Technical Sciences, 27, 172–176. Available at: https://journals.uran.ua/vestnikpgtu_tech/article/view/31526

- Neacşu, I. A., Scheichl, B., Rojacz, H., Vorlaufer, G., Varga, M., Schmid, H., Heiss, J. (2015). Transient Thermal‐Stress Analysis of Steel Slag Pots: Impact of the Solidifying‐Slag Layer on Heat Transfer and Wear. Steel Research International, 87 (6), 720–732. https://doi.org/10.1002/srin.201500203

- Rojacz, H., Neacşu, I. A., Widder, L., Varga, M., Heiss, J. (2016). Thermal effects on wear and material degradation of slag pots operating in steel production. Wear, 350-351, 35–45. https://doi.org/10.1016/j.wear.2015.12.009

- Oyama, K., Naito, M., Sato, Y., Kozai, K. (2020). Development of Long-Life Slag Pot by Optimizing Stiffness Structurally for Temperature Distribution. AISTech2020 Proceedings of the Iron and Steel Technology Conference. https://doi.org/10.33313/380/241

- Szklarz, A., Bydałek, A. W., Migas, P., Pytel, A., Jaśkowiec, K., Bitka, A. et al. (2022). Analysis of Thermal Interactions in the Slag Pots for Transporting Copper Slags. International Journal of Heat and Technology, 40 (2), 646–652. https://doi.org/10.18280/ijht.400236

- Benasciutti, D., Brusa, E., Bazzaro, G. (2010). Finite elements prediction of thermal stresses in work roll of hot rolling mills. Procedia Engineering, 2 (1), 707–716. https://doi.org/10.1016/j.proeng.2010.03.076

- Singh, N., Kaur, J., Thakur, P. (2022). Analysis of thermal stresses in different materials: A systematic review. AIP Conference Proceedings. https://doi.org/10.1063/5.0095799

- Prihod'ko, E. V., Togobitskaya, D. N., Hamhot'ko, A. F., Stepanenko, D. A. (2013). Prognozirovanie fiziko-himicheskih svoystv oksidnyh sistem. Dnepropetrovsk: Porogi, 344.

- Timoshenko, S. (1976). Strength of Materials. Part 2. Advanced Theory and Problems. Melbourne (Florida): Krieger Publishing Company, 588.

- Guo, Y., Wen, S.-R., Sun, J.-Y., He, X.-T. (2022). Theoretical Study on Thermal Stresses of Metal Bars with Different Moduli in Tension and Compression. Metals, 12 (2), 347. https://doi.org/10.3390/met12020347

- Bathe, K.-J. (2016). Finite element Procedures. Prentice Hall, 1043.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Viktor Povorotnii, Iryna Shcherbyna, Serhiі Zdanevych, Nina Diachenko, Tetiana Kimstach, Lyudmila Solonenko, Ruslan Usenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.