Identifying the effect of polymer composition in hot mix asphalt modification

DOI:

https://doi.org/10.15587/1729-4061.2024.299189Keywords:

hot mix asphalt, synthetic rubber, Marshall test, optimal asphalt contentAbstract

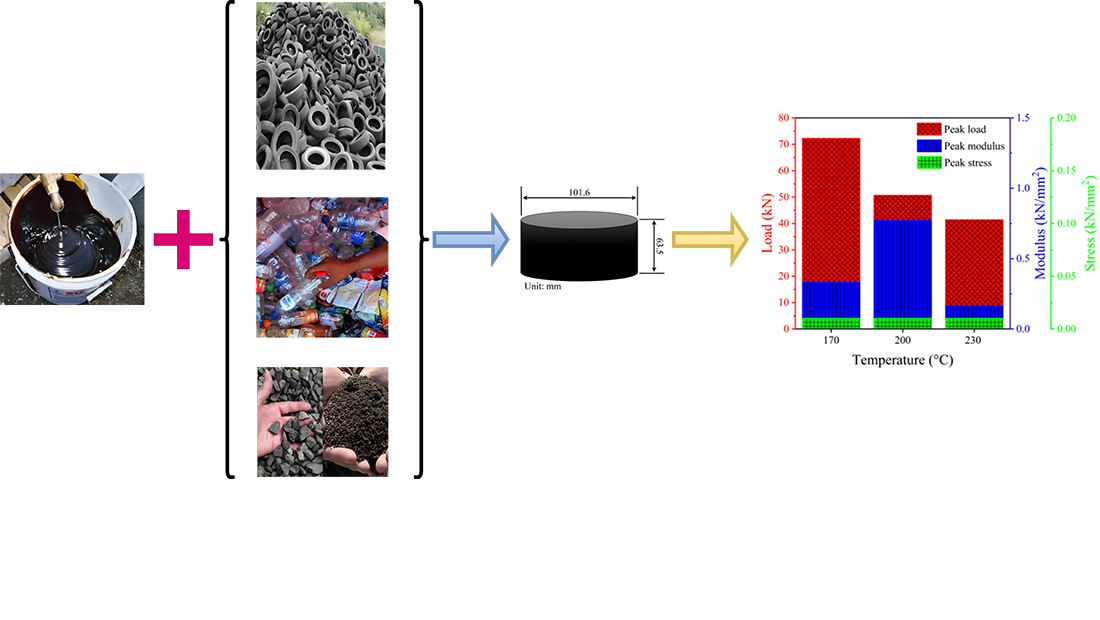

The effect of polymer composition on hot mix asphalt (HMA) is the primary focus of this research. The primary goal is to examine how temperature affects HMA's mechanical characteristics and performance, especially concerning polymer concentration. Polymer composition and modifications to HMA, including synthetic rubber and high-density polyethylene (HDPE), are the object of this research. Optimizing HMA polymer mix to improve durability, load-bearing capacity, and structural integrity is the study's key issue. The study also seeks to understand the intricate interaction between polymer concentration and HMA parameters, such as compressive strength, modulus, and stress. The research findings indicate that the maximum load of 68.169 kN was achieved with a mixture containing 5 % synthetic rubber at a temperature of 200 °C. The material exhibited stiffness and resistance to deformation, with an average crack size of 0.01 kN/mm2 and a modulus value of 0.309 kN/mm2. According to the Marshall function, the optimal blend consists of 5 % asphalt mixed at 175 °C. The results indicate that polymer mix considerably affects HMA's mechanical properties, particularly load-bearing capacity and deformation resistance. To optimize HMA performance, polymer content and temperature must be optimized. The results show that HMA with 5 % synthetic rubber under specified temperature settings has better mechanical qualities, including load-bearing capacity and stiffness. These findings help optimize polymer composition for HMA performance. These findings can be used to create more lasting and eco-friendly paving solutions. Road engineers and designers can extend asphalt pavement life and reduce environmental effects by adjusting the HMA polymer mix and temperature

References

- Caputo, P., Porto, M., Angelico, R., Loise, V., Calandra, P., Oliviero Rossi, C. (2020). Bitumen and asphalt concrete modified by nanometer-sized particles: Basic concepts, the state of the art and future perspectives of the nanoscale approach. Advances in Colloid and Interface Science, 285, 102283. https://doi.org/10.1016/j.cis.2020.102283

- Al-Gurah, E. R., Al-Humeidawi, B. H. (2023). Assessment of performance of hot mix asphalt contained various types of mineral fillers and newly polymer modified bitumen. Materials Today: Proceedings, 80, 3877–3886. https://doi.org/10.1016/j.matpr.2021.07.406

- Menapace, I., Yiming, W., Masad, E. (2018). Effects of Environmental Factors on the Chemical Composition of Asphalt Binders. Energy & Fuels, 33 (4), 2614–2624. https://doi.org/10.1021/acs.energyfuels.8b03273

- Ekejiuba, A. I. B. (2021). Natural Petroleum: Chemistry and Valuable Products Fractions. Inter- World Journal Of Science And Technology, 4 (2), 300–337. Available at: https://www.researchgate.net/publication/350790219_Natural_Petroleum_Chemistry_and_Valuable_Products_Fractions

- Li, R., Xiao, F., Amirkhanian, S., You, Z., Huang, J. (2017). Developments of nano materials and technologies on asphalt materials – A review. Construction and Building Materials, 143, 633–648. https://doi.org/10.1016/j.conbuildmat.2017.03.158

- Behnood, A., Modiri Gharehveran, M. (2019). Morphology, rheology, and physical properties of polymer-modified asphalt binders. European Polymer Journal, 112, 766–791. https://doi.org/10.1016/j.eurpolymj.2018.10.049

- Sun, D., Lu, T., Xiao, F., Zhu, X., Sun, G. (2017). Formulation and aging resistance of modified bio-asphalt containing high percentage of waste cooking oil residues. Journal of Cleaner Production, 161, 1203–1214. https://doi.org/10.1016/j.jclepro.2017.06.155

- Revelo, C. F., Correa, M., Aguilar, C., Colorado, H. A. (2021). Composite materials made of waste tires and polyurethane resin: A case study of flexible tiles successfully applied in industry. Case Studies in Construction Materials, 15, e00681. https://doi.org/10.1016/j.cscm.2021.e00681

- Al-Sabaeei, A., Yussof, N. I. Md., Napiah, M., Sutanto, M. (2019). A review of using natural rubber in the modification of bitumen and asphalt mixtures used for road construction. Jurnal Teknologi, 81 (6). https://doi.org/10.11113/jt.v81.13487

- Wu, X., Lu, C., Han, Y., Zhou, Z., Yuan, G., Zhang, X. (2016). Cellulose nanowhisker modulated 3D hierarchical conductive structure of carbon black/natural rubber nanocomposites for liquid and strain sensing application. Composites Science and Technology, 124, 44–51. https://doi.org/10.1016/j.compscitech.2016.01.012

- Gogoi, R., Biligiri, K. P., Das, N. C. (2015). Performance prediction analyses of styrene-butadiene rubber and crumb rubber materials in asphalt road applications. Materials and Structures, 49 (9), 3479–3493. https://doi.org/10.1617/s11527-015-0733-0

- Yu, H., Leng, Z., Zhou, Z., Shih, K., Xiao, F., Gao, Z. (2017). Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. Journal of Cleaner Production, 141, 336–345. https://doi.org/10.1016/j.jclepro.2016.09.043

- Nciri, N., Kim, N., Cho, N. (2017). New insights into the effects of styrene-butadiene-styrene polymer modifier on the structure, properties, and performance of asphalt binder: The case of AP-5 asphalt and solvent deasphalting pitch. Materials Chemistry and Physics, 193, 477–495. https://doi.org/10.1016/j.matchemphys.2017.03.014

- Raza, A., Khan, I., Tufail, R., Frankovska, J., Mushtaq, M., Salmi, A. et al. (2022). Evaluation of Moisture Damage Potential in Hot Mix Asphalt Using Polymeric Aggregate Treatment. Materials, 15 (15), 5437. https://doi.org/10.3390/ma15155437

- Hossein Hamedi, G., Ghalandari Shamami, K., Mazhari Pakenari, M. (2020). Effect of ultra-high-molecular-weight polyethylene on the performance characteristics of hot mix asphalt. Construction and Building Materials, 258, 119729. https://doi.org/10.1016/j.conbuildmat.2020.119729

- Tahmoorian, F., Liyanapathirana, S., Yeaman, J., Egwurube, J. (2023). Performance of Hot-Mix Asphalt and Modified Binders Containing Polyethylene. Journal of Transportation Engineering, Part B: Pavements, 149 (1). https://doi.org/10.1061/jpeodx.pveng-502

- Wu, W., Cavalli, M. C., Jiang, W., Kringos, N. (2024). Differing perspectives on the use of high-content SBS polymer-modified bitumen. Construction and Building Materials, 411, 134433. https://doi.org/10.1016/j.conbuildmat.2023.134433

- Masad, E., Roja, K. L., Rehman, A., Abdala, A. (2020). A review of asphalt modification using plastics: a focus on polyethylene. Qatar. https://doi.org/10.13140/RG.2.2.36633.77920

- Jitsangiam, P., Nusit, K., Teeratitayangkul, P., Ping Ong, G., Thienchai, C. (2023). Development of a modified Marshall mix design for Hot-mix asphalt concrete mixed with recycled plastic based on dry mixing processes. Construction and Building Materials, 404, 133127. https://doi.org/10.1016/j.conbuildmat.2023.133127

- Zhdaniuk, V., Volovyk, O., Kostin, D., Lisovin, S. (2021). An investigation of the effect of thermoplastic additives in asphalt concrete mixtures on the properties of different types of asphalt concrete. Eastern-European Journal of Enterprise Technologies, 2 (6 (110)), 61–70. https://doi.org/10.15587/1729-4061.2021.227806

- Aliha, M. R. M., Razmi, A., Mansourian, A. (2017). The influence of natural and synthetic fibers on low temperature mixed mode I + II fracture behavior of warm mix asphalt (WMA) materials. Engineering Fracture Mechanics, 182, 322–336. https://doi.org/10.1016/j.engfracmech.2017.06.003

- Kodur, V. (2014). Properties of Concrete at Elevated Temperatures. ISRN Civil Engineering, 2014, 1–15. https://doi.org/10.1155/2014/468510

- Wang, T., Xiao, F., Amirkhanian, S., Huang, W., Zheng, M. (2017). A review on low temperature performances of rubberized asphalt materials. Construction and Building Materials, 145, 483–505. https://doi.org/10.1016/j.conbuildmat.2017.04.031

- Han, L., Zheng, M., Wang, C. (2016). Current status and development of terminal blend tyre rubber modified asphalt. Construction and Building Materials, 128, 399–409. https://doi.org/10.1016/j.conbuildmat.2016.10.080

- Ruellan, B., Le Cam, J.-B., Jeanneau, I., Canévet, F., Mortier, F., Robin, E. (2019). Fatigue of natural rubber under different temperatures. International Journal of Fatigue, 124, 544–557. https://doi.org/10.1016/j.ijfatigue.2018.10.009

- Fatemi, S., Zarei, M., Ziaee, S. A., Shad, R., Amir Saadatjoo, S., Tabasi, E. (2023). Low and intermediate temperatures fracture behavior of amorphous poly alpha olefin (APAO)-modified hot mix asphalt subjected to constant and variable temperatures. Construction and Building Materials, 364, 129840. https://doi.org/10.1016/j.conbuildmat.2022.129840

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Stella Junus, Ilyas Renreng, Muhamad Syahid, Azwar Hayat

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.