Determining rational parameters for the treatment of concentrated wastewater from etching site by using combined systems producing sediments of predefined composition

DOI:

https://doi.org/10.15587/1729-4061.2024.301417Keywords:

pickling and degreasing solutions, parameters, magnetic device, sediment of predefined compositionAbstract

The object of this study is model solutions, spent sulfuric acid and chloride acid etching solutions, degreasing of metal products at enterprises.

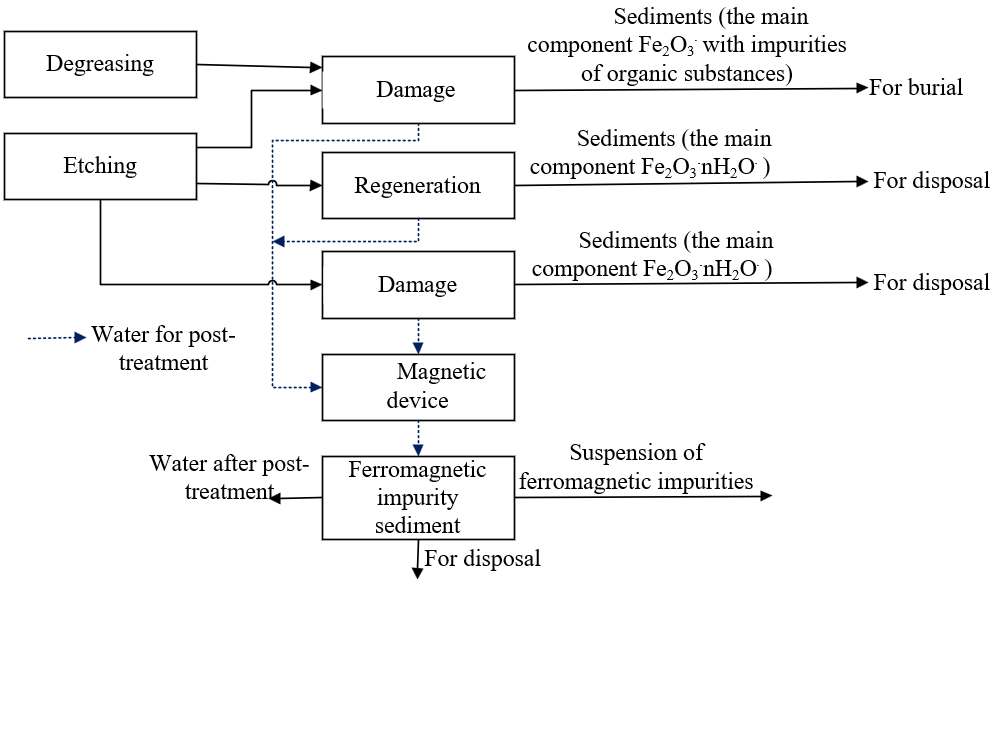

The paper reports results of research on the possibility of obtaining sediments of predefined composition and reducing the consumption of chemical reagents in comparison with conventional cleaning schemes. The systematization of the elements of the technological scheme has been shown, which provides for the treatment of concentrated wastewater of the etching area in combined systems with obtaining sediments of predefined composition and is the basis for the implementation of resource-saving technology. Rational parameters were established for the state (рН=3‒4, Eh=+0.3‒+0.33 V, and rH2=16.3–19.38 V) and technological parameters (degree of iron extraction ψ=0.8, reagent consumption from the stoichiometric norm of B=0.8). Such parameters provide the proper conditions for the oxidation of organic compounds and their co-precipitation with insoluble iron hydroxy compounds (the maximum degree of extraction of organic impurities is 86 %). The formed precipitate corresponds to the FeOOH.nH2O composition, contains 2‒3 % of organic impurities, and is subject to burial. As a result of studies on the treatment of concentrated iron-containing wastewater, the obtained sediment is ready for further utilization by processing. The composition of this sediment corresponds to the natural mineral limonite FeOOH (Fe2O3.nH2O) and is formed at pH values from 3.5 to 7.5 with rH2 values from 26 V to 21 V and at technological regeneration parameters of pH=4.0–4.6; rH2 =23.34–32.25 V.

As a result of research into the deep purification of wastewater using a magnetic device, a suspension of sediment of ferromagnetic impurities (hydroxo compounds of iron) is obtained, which could be the basis for extraction or production of magnetically favorable dispersed material.

References

- Buzan, O. V., Kovalchuk, N. V. (2022). Uzahalnenyi balans materialnykh potokiv za komponentamy stichnykh vod halvanichnoho vyrobnytstva. Studentskyi visnyk NUVHP, 1 (17), 132–135. Available at: http://ep3.nuwm.edu.ua/id/eprint/24485

- Sultan, B. B. M., Thierry, D., Torrescano-Alvarez, J. M., Ogle, K. (2022). Selective dissolution during acid pickling of aluminum alloys by element-resolved electrochemistry. Electrochimica Acta, 404, 139737. https://doi.org/10.1016/j.electacta.2021.139737

- Wieszczycka, K., Filipowiak, K., Wojciechowska, I., Buchwald, T. (2021). Efficient metals removal from waste pickling liquor using novel task specific ionic liquids - classical manner and encapsulation in polymer shell. Separation and Purification Technology, 262, 118239. https://doi.org/10.1016/j.seppur.2020.118239

- Sharma, P., Chaturvedi, P., Chandra, R., Kumar, S. (2022). Identification of heavy metals tolerant Brevundimonas sp. from rhizospheric zone of Saccharum munja L. and their efficacy in in-situ phytoremediation. Chemosphere, 295, 133823. https://doi.org/10.1016/j.chemosphere.2022.133823

- Movchan, S. I. (2015). A. s. No. 58412. Khimichni rechovyny dlia ochyshchennia, obroblennia y neitralizatsiyi okremykh vydiv stichnykh vod halvanichnoho vyrobnytstva promyslovykh pidpryiemstv. No. 58010; declareted: 02.02.2015; published: 13.10.2014.

- Plyatsuk, L., Melnik, A. (2008). Analysis of electroplating wastewater treatment in Ukraine. Transactions of Sumy State University, 2, 116–120.

- Rajoria, S., Vashishtha, M., Sangal, V. K. (2022). Treatment of electroplating industry wastewater: a review on the various techniques. Environmental Science and Pollution Research, 29 (48), 72196–72246. https://doi.org/10.1007/s11356-022-18643-y

- Yatskov, M., Korchyk, N., Budenkova, N., Kyrylyuk, S., Prorok, O. (2017). Development of technology for recycling the liquid iron-containing wastes of steel surface etching. Eastern-European Journal of Enterprise Technologies, 2 (6 (86)), 70–77. https://doi.org/10.15587/1729-4061.2017.97256

- Merentsov, N. A., Bokhan, S. A., Lebedev, V. N., Persidskiy, A. V., Balashov, V. A. (2018). System for Centralised Collection, Recycling and Removal of Waste Pickling and Galvanic Solutions and Sludge. Materials Science Forum, 927, 183–189. https://doi.org/10.4028/www.scientific.net/msf.927.183

- Xiaoyu, W., Gang, L., Shuo, Y. (2020). Study on the Treatment and Recovery of Acid in Steel Pickling Wastewater with Diffusion Dialysis. IOP Conference Series: Earth and Environmental Science, 510 (4), 042046. https://doi.org/10.1088/1755-1315/510/4/042046

- Fylypchuk, V. L., Drevetskyi, V. V., Fylypchuk, L. V., Klepach, M. I. (2017). Avtomatyzovane keruvannia pryrodo-okhoronnymy systemamy ochyshchennia metalovmisnykh stichnykh vod. Rivne: Ovid, 288.

- Kochetov, G., Samchenko, D., Lastivka, O., Derecha, D. (2022). Determining the rational parameters for processing spent etching solutions by ferritization using alternating magnetic fields. Eastern-European Journal of Enterprise Technologies, 3 (10 (117)), 21–28. https://doi.org/10.15587/1729-4061.2022.259791

- Garashchenko, I. V., Garashchenko, V. I., Astrelin, I. M. (2019). Magnetosorption purification of liquid chemical products from ferromagnetic impurities. Voprosy Khimii i Khimicheskoi Tekhnologii, 1, 80–85. https://doi.org/10.32434/0321-4095-2019-122-1-80-85

- Mehta, D., Mazumdar, S., Singh, S. K. (2015). Magnetic adsorbents for the treatment of water/wastewater – A review. Journal of Water Process Engineering, 7, 244–265. https://doi.org/10.1016/j.jwpe.2015.07.001

- Yatskov, M., Korchyk, N., Mysina, O., Budenkova, N. (2021). Creation of a combined system for treatment of iron-containing wastewater from etching operations. Technology Audit and Production Reserves, 6 (3 (62)), 21–26. https://doi.org/10.15587/2706-5448.2021.247550

- Yatskov, M. V., Korchyk, N. M., Kyryliuk, S. V. (2019). Obgruntuvannia rozpodilu kontsentrovanykh stichnykh vod halvanichnoho vyrobnytstva na katehoriyi. Zbirnyk naukovykh prats: XVII naukova konferentsiya «Lvivski khimichni chytannia – 2019». Lviv, 118.

- Yatskov, M. V., Korchyk, N. M., Prorok, O. A., Besediuk, V. Yu. (2021). Pat. No. 147127 UA. Sposib vyluchennia khromu iz vysokokontsentrovanykh vidkhodiv shkirzavodiv. No. 202006909; declareted: 28.10.2020; published: 14.04.2021, Bul. No. 15. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=275514

- Yatskov, M. V., Korchyk, N. M., Prorok, O. A. (2023). Research of the chemical parameters sedimentation for the highly concentrated ferrums containing liquid waste to obtain sediments with the specified composition and properties. Visnyk NUVHP, 2 (102), 94–107.

- Yatskov, M., Korchyk, N., Mysina, O., Budenkova, N. (2021). Improvement of the technological treatment scheme of iron-containing wastewater from etching operations. EUREKA: Life Sciences, 3, 21–28. https://doi.org/10.21303/2504-5695.2021.001883

- Yatskov, M., Korchyk, N., Budenkova, N., Mysina, O. (2022). Development of a resource-saving technology for the treatment of ferrum-containing wastewater from etching operations. Eastern-European Journal of Enterprise Technologies, 6 (10 (120)), 16–26. https://doi.org/10.15587/1729-4061.2022.267949

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Mykola Yatskov, Natalia Korchyk, Nadia Budenkova, Oksana Mysina, Svitlana Kyrylyuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.