Design of a universal low-temperature rotary apparatus for making meat and vegetable products considering the integrated adaptive mechanism

DOI:

https://doi.org/10.15587/1729-4061.2024.305550Keywords:

meat-vegetable products, multicomponent vegetable dried semi-finished product, frameless technology, temperature field uniformityAbstract

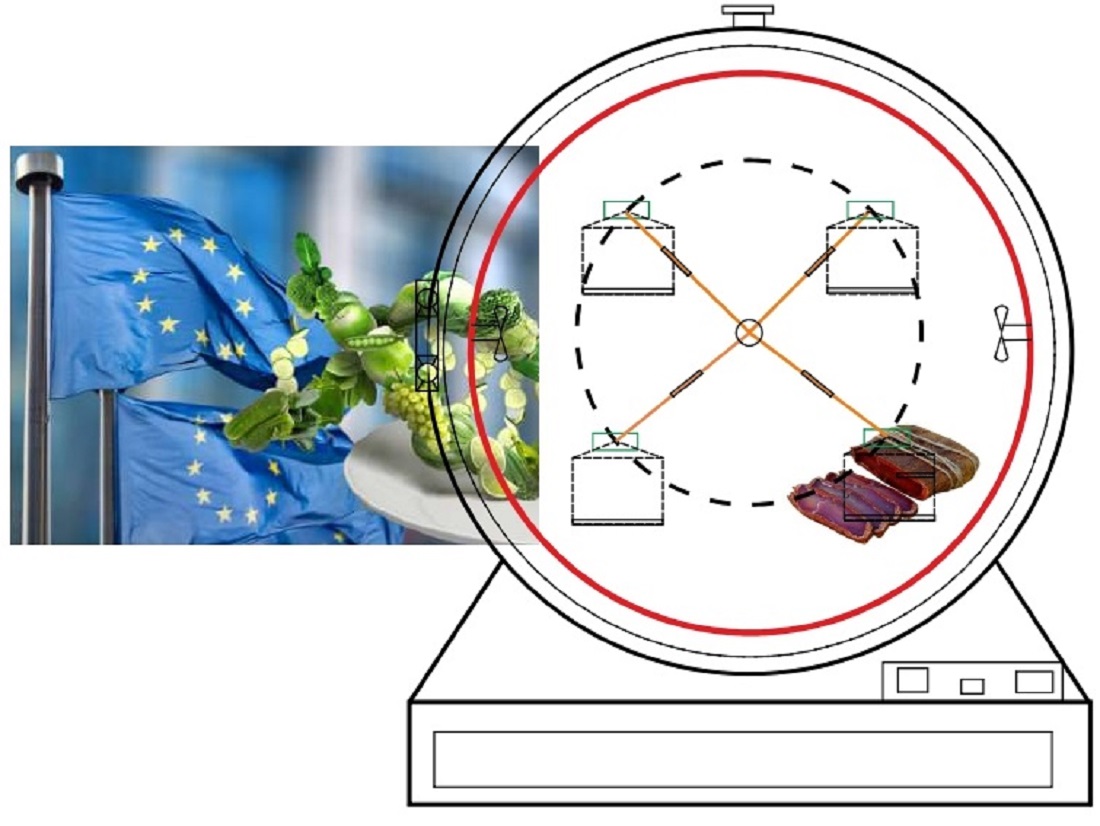

The object of this study is the implementation of low-temperature processes for the production of meat and vegetable products under the conditions of adding a dried semi-finished product of a high degree of readiness to the recipe when using the designed universal rotary device of continuous action. The rotary device of continuous action for low-temperature processing of meat and vegetable products with a cylindrical working chamber is heated by a film-like resistive electronic heater of the radiating type. It has a stationary wall (with a technical door for unloading and loading the device) and a technical wall (with an opening angle of 90°). On the inner surfaces of the walls, inclined converging ribs with an angle of 25° are installed, which are covered with an electric heater. Semi-finished meat and vegetable products are loaded onto carts with technological containers and mounted on a frameless drum (rotation frequency 0.03...0.06 s–1). The device converts secondary thermal energy into low-voltage power supply voltage (~3...8 W) for autonomous operation of fans.

The proposed integrated adaptive mechanism for the system of complex interaction of the agricultural, processing, and production sectors implies the formation of resource efficiency of production processes from "farm to table". The designed device implements the process of frying meat-vegetable bread under conditions of reaching 80 °C in the center of the product. The obtained temperature field data confirm the uniformity of the temperature field during frying of the product (cooking readiness of the product at the initial weight of 650±20 g – 4.0 hours). The introduction of a multicomponent dried fraction based on potatoes, Jerusalem artichokes, zucchini, and carrots into the recipe of meat-vegetable bread reduces the weight loss of the semi-finished product during frying by 12.3 %. It increases the content of calcium, phosphorus, vitamin C accompanied with a decrease in energy value by 28.1 %

References

- Galanakis, C. M., Rizou, M., Aldawoud, T. M. S., Ucak, I., Rowan, N. J. (2021). Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends in Food Science & Technology, 110, 193–200. https://doi.org/10.1016/j.tifs.2021.02.002

- Munekata, P. E. S., Pérez-Álvarez, J. Á., Pateiro, M., Viuda-Matos, M., Fernández-López, J., Lorenzo, J. M. (2021). Satiety from healthier and functional foods. Trends in Food Science & Technology, 113, 397–410. https://doi.org/10.1016/j.tifs.2021.05.025

- Sgroi, F. (2021). Food traditions and consumer preferences for cured meats: Role of information in geographical indications. International Journal of Gastronomy and Food Science, 25, 100386. https://doi.org/10.1016/j.ijgfs.2021.100386

- Demchenko, O., Basiurkina, N., Popadynets, N., Minenko, S., Sokoliuk, K. (2023). Factors and Determinants of the Development of Human Capital in Rural Areas in the Conditions of Global Challenges. ECONOMICS, 11 (s1), 93–108. https://doi.org/10.2478/eoik-2023-0026

- Koliadenko, S., Andreichenko, A., Galperina, L., Minenko, S., Kovylina, M. (2020). Analysis and forecasting of Ukrainian agrarian exports to the EU countries. Agricultural and Resource Economics: International Scientific E-Journal, 6 (3), 29–47. https://doi.org/10.51599/are.2020.06.03.02

- Pap, N., Fidelis, M., Azevedo, L., do Carmo, M. A. V., Wang, D., Mocan, A. et al. (2021). Berry polyphenols and human health: evidence of antioxidant, anti-inflammatory, microbiota modulation, and cell-protecting effects. Current Opinion in Food Science, 42, 167–186. https://doi.org/10.1016/j.cofs.2021.06.003

- Zahorulko, A., Zagorulko, A., Mikhaylov, V., Liashenko, B. (2023). Improving a technique for making fried meat chopped semi-finished products in functionally closed environments with the addition of blended dried semi-finished product. Eastern-European Journal of Enterprise Technologies, 5 (11 (125)), 6–15. https://doi.org/10.15587/1729-4061.2023.290134

- Altenburg, D., Spruyt, A. (2022). Predicting meat consumption from concurrent, automatic appraisals: Introducing nuance to product appraisals. Appetite, 170, 105847. https://doi.org/10.1016/j.appet.2021.105847

- McBey, D., Watts, D., Johnstone, A. M. (2019). Nudging, formulating new products, and the lifecourse: A qualitative assessment of the viability of three methods for reducing Scottish meat consumption for health, ethical, and environmental reasons. Appetite, 142, 104349. https://doi.org/10.1016/j.appet.2019.104349

- Ramos-Diaz, J. M., Kantanen, K., Edelmann, J. M., Jouppila, K., Sontag-Strohm, T., Piironen, V. (2022). Functionality of oat fiber concentrate and faba bean protein concentrate in plant-based substitutes for minced meat. Current Research in Food Science, 5, 858–867. https://doi.org/10.1016/j.crfs.2022.04.010

- Zahorulko, A., Zagorulko, A., Yancheva, M., Savinok, O., Yakovets, L., Zhelievа, T. et al. (2023). Improving the production technique of meat chopped semi-finished products with the addition of dried semi-finished product with a high degree of readiness. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 6–14. https://doi.org/10.15587/1729-4061.2023.276249

- Hocquette, J.-F. (2023). Consumer perception of livestock production and meat consumption; an overview of the special issue “Perspectives on consumer attitudes to meat consumption.” Meat Science, 200, 109163. https://doi.org/10.1016/j.meatsci.2023.109163

- Rocca-Poliméni, R., Zárate Vilet, N., Roux, S., Bailleul, J.-L., Broyart, B. (2019). Continuous measurement of contact heat flux during minced meat grilling. Journal of Food Engineering, 242, 163–171. https://doi.org/10.1016/j.jfoodeng.2018.08.032

- Alfieri, F., Rivero-Pino, F., Zakidou, P., Fernandez-Dumont, A Roldán-Torres, R. (2023). Processes for Obtaining Plant-Based Dairy and Meat Substitutes. Sustainable Food Science - A Comprehensive Approach, 75–99. https://doi.org/10.1016/b978-0-12-823960-5.00051-2

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. https://doi.org/10.15587/1729-4061.2021.240675

- Janardhanan, R., Huerta-Leidenz, N., Ibañez, F. C., Beriain, M. J. (2023). High-pressure processing and sous-vide cooking effects on physicochemical properties of meat-based, plant-based and hybrid patties. LWT, 173, 114273. https://doi.org/10.1016/j.lwt.2022.114273

- Kor, G., Icier, F. (2016). Thermal imaging during infrared final cooking of semi-processed cylindrical meat product. Infrared Physics & Technology, 79, 242–251. https://doi.org/10.1016/j.infrared.2016.11.002

- Zahorulko, A., Zagorulko, A., Savytska, N., Minenko, S., Pugach, A., Ponomarenko, N. et al. (2023). Design of a universal apparatus for heat treatment of meat and vegetable cooked and smoked products with the addition of dried semi-finished products of a high degree of readiness to the recipe. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 73–82. https://doi.org/10.15587/1729-4061.2023.285406

- Kasiyanchuk, V. D. (2013). Sukhyi produkt topinambura - efektyvnyi napivfabrykat dlia vyrobnytstva produktsii likuvalno-profilaktychnoho pryznachennia. Halytskyi likarskyi visnyk, 21 (3), 103–105. Available at: http://nbuv.gov.ua/UJRN/glv_2014_21_3_41

- Telezhenko, L. N., Bezusov, A. T. (2004). Biologicheski aktivnye veshchestva fruktov i ovoshchey i ih sohranenie pri pererabotke. Odessa: «Optimum», 268.

- Yudina, T., Nazarenko, I. (2016). Technological parameters and modes of getting mashed zucchini with specified functional and technological properties. Pratsi TDATU, 1 (16), 142–149. Available at: http://nauka.tsatu.edu.ua/print-journals-tdatu/16-1/16_1/21.pdf

- Cherevko, A., Kiptelaya, L., Mikhaylov, V., Zagorulko, A., Zagorulko, A. (2015). Development of energy-efficient ir dryer for plant raw materials. Eastern-European Journal of Enterprise Technologies, 4 (8 (76)), 36–41. https://doi.org/10.15587/1729-4061.2015.47777

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. https://doi.org/10.15587/1729-4061.2022.254873

- Zahorulko, A. M., Zahorulko, O. Ye. (2016). Pat. No. 108041 UA. Hnuchkyi plivkovyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. No. u201600827; declareted: 02.20.2016; published: 24.06.2016, Bul. No. 12. Available at: http://uapatents.com/5-108041-gnuchkijj-plivkovijj-rezistivnijj-elektronagrivach-viprominyuyuchogo-tipu.html

- Babanov, I. H., Mykhailov, V. M., Shevchenko, A. O., Mykhailova, S. V. (2018). Perspektyvy sposobu zharennia kulinarnykh vyrobiv z elektrokontaktnym teplovym vplyvom. Kharchova promyslovist, 23, 62–66. Available at: http://dspace.nuft.edu.ua/handle/123456789/29928

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Zahorulko, Nataliia Penkina, Tetiana Zhelievа, Hanna Chmil, Maksym Prykhodko, Oleksandr Kobets, Svitlana Nuzhna

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.