Reducing operational costs in a manufacturing system that incorporates quality assurances, probabilistic failures, overtime and outsourcing

DOI:

https://doi.org/10.15587/1729-4061.2024.306083Keywords:

cost reduction, quality assurance, probabilistic failures, overtime, outsourcing, optimization, manufacturingAbstract

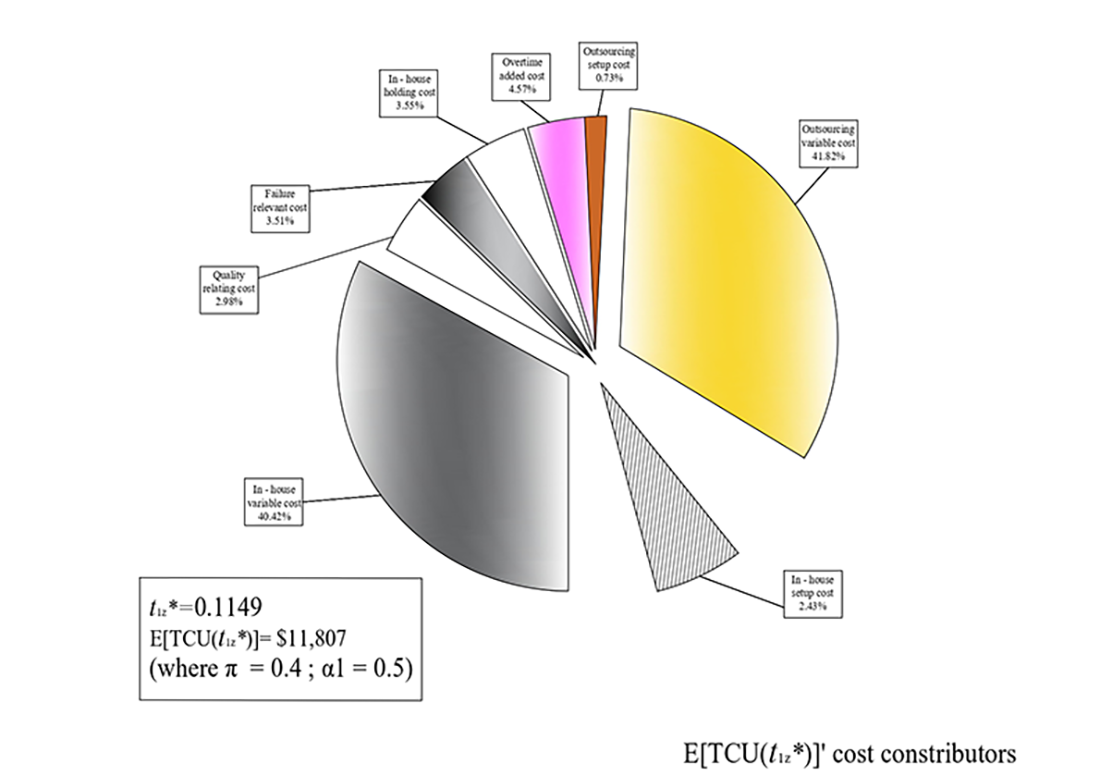

This research focuses on the dynamic landscape of today's competitive market, where production management must meet clients' expectations for high-quality products and shorter lead times while managing internal disruptions due to inevitable defects and unpredictable equipment failures. Achieving these operational goals without compromising product quality, missing deadlines, or experiencing production disruptions is essential for minimizing operational expenses. The study examines the dynamics of the system's operating costs through the development of models, mathematical formulations, optimization techniques, and algorithm proposals. It demonstrates the system's convexity and establishes the optimal batch time for implementing the proposed methodologies. The research results show relevant failure costs of 3.51 %, overtime added costs of 4.57 %, outsourcing setup costs of 0.73 %, outsourcing variable costs of 41.82 %, quality-related costs of 2.98 %, in-house variable costs of 40.42 %, and in-house holding costs of 3.55 %. The study develops strategies for optimal overtime use to meet production targets without excessive labor costs and provides a structured framework for making informed outsourcing decisions that balance cost savings with quality and reliability considerations.

Overall, the research provides a robust framework for reducing operational costs while maintaining or improving the quality and reliability of manufacturing processes

References

- Chiu, S. W. (2010). Robust planning in optimization for production system subject to random machine breakdown and failure in rework. Computers & Operations Research, 37 (5), 899–908. https://doi.org/10.1016/j.cor.2009.03.016

- Chiu, S. W., You, L.-W., Sung, P.-C., Wang, Y. (2020). Determining the fabrication runtime for a buyer-vendor system with stochastic breakdown, accelerated rate, repairable items, and multi-delivery strategy. International Journal of Industrial Engineering Computations, 11 (4), 491–508. https://doi.org/10.5267/j.ijiec.2020.6.002

- Chiu, S. W., Wu, H.-Y., Yeh, T.-M., Wang, Y. (2021). Solving a hybrid batch production problem with unreliable equipment and quality reassurance. International Journal of Industrial Engineering Computations, 12, 235–248. https://doi.org/10.5267/j.ijiec.2021.4.001

- Ghobakhloo, M., Iranmanesh, M., Foroughi, B., Rejeb, A., Nikbin, D., Tseng, M.-L. (2024). A practical guide on strategic roadmapping for information and operations technology management: a case study on industry 5.0 transformation. Journal of Industrial and Production Engineering, 41 (5), 397–421. https://doi.org/10.1080/21681015.2024.2325687

- Peter Chiu, Y.-S., Chiu, T., Pai, F.-Y., Wu, H. Y. (2021). A producer-retailer incorporated multi-item EPQ problem with delayed differentiation, the expedited rate for common parts, multi-delivery and scrap. International Journal of Industrial Engineering Computations, 12 (4), 427–440. https://doi.org/10.5267/j.ijiec.2021.5.001

- Ahmadi Nezhad, A. M., Mazloum, M., Bakhshi, A., Jolai, F., Aghsami, A. (2024). E-channel management under vendor-managed inventory by option and conventional contracts: the influence of outsourcing decisions. Journal of Industrial and Production Engineering, 41 (5), 456–485. https://doi.org/10.1080/21681015.2024.2333373

- Dewi, D., Hajadi, F., Handranata, Y. W., Herlina, M. G. (2021). The effect of service quality and customer satisfaction toward customer loyalty in service industry. Uncertain Supply Chain Management, 9 (3), 631–636. https://doi.org/10.5267/j.uscm.2021.5.007

- Di Nardo, M., Madonna, M., Addonizio, P., Gallab, M. (2021). A Mapping Analysis of Maintenance in Industry 4.0. Journal of Applied Research and Technology, 19 (6), 653–675. https://doi.org/10.22201/icat.24486736e.2021.19.6.1460

- Ebrahim, Z., Abdul Rasib, A. H. (2017). Unnecessary overtime as a component of time loss measures in assembly processes. Journal of Advanced Manufacturing Technology, 11 (1), 37–47.

- Ostad Ali Akbari, V., Schuppisser, C., Kuffa, M., Wegener, K. (2024). Automated machine tool dynamics identification for predicting milling stability charts in industrial applications. The International Journal of Advanced Manufacturing Technology, 130 (11-12), 5879–5893. https://doi.org/10.1007/s00170-024-12952-x

- Gupta, P., Chawla, V. K., Jain, V., Angra, S. (2022). Green operations management for sustainable development: An explicit analysis by using fuzzy best-worst method. Decision Science Letters, 357–366. https://doi.org/10.5267/j.dsl.2022.1.003

- Heydari, J., Govindan, K., Ebrahimi Nasab, H. R., Taleizadeh, A. A. (2020). Coordination by quantity flexibility contract in a two-echelon supply chain system: Effect of outsourcing decisions. International Journal of Production Economics, 225, 107586. https://doi.org/10.1016/j.ijpe.2019.107586

- Iqbal, T. (2020). Investigating logistics issues in service quality of SMEs in Saudi Arabia. Uncertain Supply Chain Management, 8, 875–886. https://doi.org/10.5267/j.uscm.2020.5.005

- Ishida, Y., Murayama, H., Fukuda, Y. (2020). Association Between Overtime-Working Environment and Psychological Distress Among Japanese Workers. Journal of Occupational & Environmental Medicine, 62 (8), 641–646. https://doi.org/10.1097/jom.0000000000001920

- Najafi, M., Ghodratnama, A., Pasandideh, H. R. (2018). Solving a deterministic multi product single machine EPQ model withpartial backordering, scrapped products and rework. International Journal of Supply and Operations Management, 5 (1), 11–27. https://doi.org/10.22034/2018.1.2

- Ouaddi, K., Mhada, F.-Z., Benadada, Y. (2020). Memetic algorithm for multi-tours dynamic vehicle routing problem with overtime (MDVRPOT). International Journal of Industrial Engineering Computations, 11, 643–662. https://doi.org/10.5267/j.ijiec.2020.4.001

- Patil, A. S., Pisal, M. V., Suryavanshi, C. T. (2021). Application of value stream mapping to enhance productivity by reducing manufacturing lead time in a manufacturing company: A case study. Journal of Applied Research and Technology, 19 (1), 11–22. https://doi.org/10.22201/icat.24486736e.2021.19.1.1488

- Rafiee, K., Rabbani, M., Rafiei, H., Rahimi-Vahed, A. (2011). A new approach towards integrated cell formation and inventory lot sizing in an unreliable cellular manufacturing system. Applied Mathematical Modelling, 35 (4), 1810–1819. https://doi.org/10.1016/j.apm.2010.10.011

- Ramasubbu, N., Shang, J., May, J. H., Tjader, Y., Vargas, L. (2019). Task Interdependence and Firm Performance in Outsourced Service Operations. Manufacturing & Service Operations Management, 21 (3), 658–673. https://doi.org/10.1287/msom.2018.0716

- Reynard, P. C. (1998). Manufacturing Strategies in the Eighteenth Century: Subcontracting for Growth among Papermakers in the Auvergne. The Journal of Economic History, 58 (1), 155–182. https://doi.org/10.1017/s0022050700019926

- Rouhani, S., Pishvaee, M. S., Zarrinpoor, N. (2021). A fuzzy optimization approach to strategic organ transplantation network design problem: A real case study. Decision Science Letters, 10 (3), 195–216. https://doi.org/10.5267/j.dsl.2021.5.001

- Sung, P.-C., Lai, C.-M., Wang, Y., Chiu, Y.-S. P. (2022). Minimization of multiproduct fabrication cost featuring rework, commonality, external provider, and postponement. Uncertain Supply Chain Management, 10 (2), 353–364. https://doi.org/10.5267/j.uscm.2022.1.003

- Waiyawuththanapoom, P., Jermsittiparsert, K. (2022). The role of sustainable HRM in supply chain, profitability and resource utilization. Uncertain Supply Chain Management, 10 (2), 365–374. https://doi.org/10.5267/j.uscm.2022.1.002

- Youssef, A. M. A., ElMaraghy, H. A. (2008). Performance analysis of manufacturing systems composed of modular machines using the universal generating function. Journal of Manufacturing Systems, 27 (2), 55–69. https://doi.org/10.1016/j.jmsy.2008.07.003

- Zhu, S. X. (2015). Dynamic replenishment from two sources with different yields, costs, and leadtimes. International Journal of Production Economics, 165, 79–89. https://doi.org/10.1016/j.ijpe.2015.03.026

- Chen, W., Li, W., Wu, J., Wang, R., Liu, W., Xu, F. (2024). Fabrication of superior conductive composite yarn with 3D continuous CNT/WPU structure for high-performance stretchable heater and sensor. Composites Part A: Applied Science and Manufacturing, 185, 108289. https://doi.org/10.1016/j.compositesa.2024.108289

- Ramakrishna, Y., Alzoubi, H. (2022). Empirical Investigation of Mediating Role of Six Sigma Approach in Rationalizing the COQ in Service Organizations. Operations and Supply Chain Management: An International Journal, 15 (1), 122–135. https://doi.org/10.31387/oscm0480335

- Rizki, A. F., Augustine, Y. (2022). Green supply chain management practices: direct effects sustainability performance. Technium Social Sciences Journal, 28, 389–407. https://doi.org/10.47577/tssj.v28i1.5795

- Yassin, N. (2022). Development and Implementation of Quality Assurance According to GMP Guidelines in Lebanese Pharmaceutical Companies. Technium Social Sciences Journal, 37, 324–340. https://doi.org/10.47577/tssj.v37i1.7605

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Wirda Novarika, Sony Bahagia Sinaga, Satria Yudha Prayogi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.