Зниження експлуатаційних витрат у виробничій системі, включаючи забезпечення якості, ймовірнісні відмови, понаднормову роботу та аутсорсинг

DOI:

https://doi.org/10.15587/1729-4061.2024.306083Ключові слова:

зниження витрат, забезпечення якості, ймовірнісні відмови, понаднормова робота, аутсорсинг, оптимізація, виробництвоАнотація

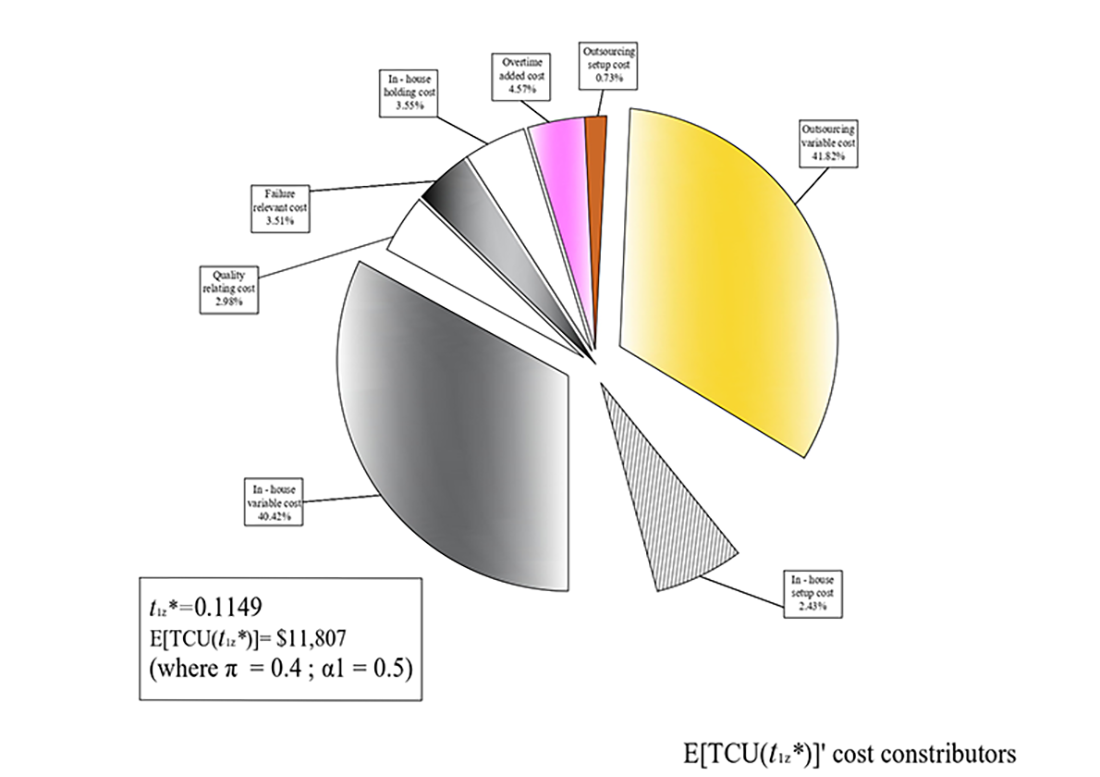

Дане дослідження зосереджено на динамічному ландшафті сучасного конкурентного ринку, при якому управління виробництвом має відповідати очікуванням клієнтів щодо високоякісної продукції та скорочення термінів виконання замовлень, з одночасним усуненням внутрішніх збоїв внаслідок неминучих дефектів і непередбачуваних відмов обладнання. Досягнення цих операційних цілей без шкоди для якості продукції, зриву термінів чи збоїв виробництва має важливе значення для мінімізації експлуатаційних витрат. У дослідженні розглядається динаміка експлуатаційних витрат системи за допомогою розробки моделей, математичних формул, методів оптимізації та алгоритмів. Показана багатогранність системи та встановлено оптимальний час обробки партії для реалізації запропонованих методологій. За результатами дослідження, відповідні витрати внаслідок відмов становлять 3,51 %, додаткові витрати на понаднормову роботу – 4,57 %, витрати на організацію аутсорсингу – 0,73 %, змінні витрати на аутсорсинг – 41,82 %, витрати, пов'язані з якістю – 2,98 %, внутрішні змінні витрати – 40,42 % і внутрішні витрати на утримання – 3,55 %. У дослідженні розробляються стратегії оптимального використання понаднормових робіт для досягнення виробничих цілей без надмірних витрат праці та надається структурована основа для прийняття обґрунтованих рішень з аутсорсингу, що забезпечують баланс між зниженням витрат і міркуваннями якості та надійності.

В цілому, дослідження забезпечує надійну основу для зниження експлуатаційних витрат при одночасному збереженні або поліпшенні якості та надійності виробничих процесів

Посилання

- Chiu, S. W. (2010). Robust planning in optimization for production system subject to random machine breakdown and failure in rework. Computers & Operations Research, 37 (5), 899–908. https://doi.org/10.1016/j.cor.2009.03.016

- Chiu, S. W., You, L.-W., Sung, P.-C., Wang, Y. (2020). Determining the fabrication runtime for a buyer-vendor system with stochastic breakdown, accelerated rate, repairable items, and multi-delivery strategy. International Journal of Industrial Engineering Computations, 11 (4), 491–508. https://doi.org/10.5267/j.ijiec.2020.6.002

- Chiu, S. W., Wu, H.-Y., Yeh, T.-M., Wang, Y. (2021). Solving a hybrid batch production problem with unreliable equipment and quality reassurance. International Journal of Industrial Engineering Computations, 12, 235–248. https://doi.org/10.5267/j.ijiec.2021.4.001

- Ghobakhloo, M., Iranmanesh, M., Foroughi, B., Rejeb, A., Nikbin, D., Tseng, M.-L. (2024). A practical guide on strategic roadmapping for information and operations technology management: a case study on industry 5.0 transformation. Journal of Industrial and Production Engineering, 41 (5), 397–421. https://doi.org/10.1080/21681015.2024.2325687

- Peter Chiu, Y.-S., Chiu, T., Pai, F.-Y., Wu, H. Y. (2021). A producer-retailer incorporated multi-item EPQ problem with delayed differentiation, the expedited rate for common parts, multi-delivery and scrap. International Journal of Industrial Engineering Computations, 12 (4), 427–440. https://doi.org/10.5267/j.ijiec.2021.5.001

- Ahmadi Nezhad, A. M., Mazloum, M., Bakhshi, A., Jolai, F., Aghsami, A. (2024). E-channel management under vendor-managed inventory by option and conventional contracts: the influence of outsourcing decisions. Journal of Industrial and Production Engineering, 41 (5), 456–485. https://doi.org/10.1080/21681015.2024.2333373

- Dewi, D., Hajadi, F., Handranata, Y. W., Herlina, M. G. (2021). The effect of service quality and customer satisfaction toward customer loyalty in service industry. Uncertain Supply Chain Management, 9 (3), 631–636. https://doi.org/10.5267/j.uscm.2021.5.007

- Di Nardo, M., Madonna, M., Addonizio, P., Gallab, M. (2021). A Mapping Analysis of Maintenance in Industry 4.0. Journal of Applied Research and Technology, 19 (6), 653–675. https://doi.org/10.22201/icat.24486736e.2021.19.6.1460

- Ebrahim, Z., Abdul Rasib, A. H. (2017). Unnecessary overtime as a component of time loss measures in assembly processes. Journal of Advanced Manufacturing Technology, 11 (1), 37–47.

- Ostad Ali Akbari, V., Schuppisser, C., Kuffa, M., Wegener, K. (2024). Automated machine tool dynamics identification for predicting milling stability charts in industrial applications. The International Journal of Advanced Manufacturing Technology, 130 (11-12), 5879–5893. https://doi.org/10.1007/s00170-024-12952-x

- Gupta, P., Chawla, V. K., Jain, V., Angra, S. (2022). Green operations management for sustainable development: An explicit analysis by using fuzzy best-worst method. Decision Science Letters, 357–366. https://doi.org/10.5267/j.dsl.2022.1.003

- Heydari, J., Govindan, K., Ebrahimi Nasab, H. R., Taleizadeh, A. A. (2020). Coordination by quantity flexibility contract in a two-echelon supply chain system: Effect of outsourcing decisions. International Journal of Production Economics, 225, 107586. https://doi.org/10.1016/j.ijpe.2019.107586

- Iqbal, T. (2020). Investigating logistics issues in service quality of SMEs in Saudi Arabia. Uncertain Supply Chain Management, 8, 875–886. https://doi.org/10.5267/j.uscm.2020.5.005

- Ishida, Y., Murayama, H., Fukuda, Y. (2020). Association Between Overtime-Working Environment and Psychological Distress Among Japanese Workers. Journal of Occupational & Environmental Medicine, 62 (8), 641–646. https://doi.org/10.1097/jom.0000000000001920

- Najafi, M., Ghodratnama, A., Pasandideh, H. R. (2018). Solving a deterministic multi product single machine EPQ model withpartial backordering, scrapped products and rework. International Journal of Supply and Operations Management, 5 (1), 11–27. https://doi.org/10.22034/2018.1.2

- Ouaddi, K., Mhada, F.-Z., Benadada, Y. (2020). Memetic algorithm for multi-tours dynamic vehicle routing problem with overtime (MDVRPOT). International Journal of Industrial Engineering Computations, 11, 643–662. https://doi.org/10.5267/j.ijiec.2020.4.001

- Patil, A. S., Pisal, M. V., Suryavanshi, C. T. (2021). Application of value stream mapping to enhance productivity by reducing manufacturing lead time in a manufacturing company: A case study. Journal of Applied Research and Technology, 19 (1), 11–22. https://doi.org/10.22201/icat.24486736e.2021.19.1.1488

- Rafiee, K., Rabbani, M., Rafiei, H., Rahimi-Vahed, A. (2011). A new approach towards integrated cell formation and inventory lot sizing in an unreliable cellular manufacturing system. Applied Mathematical Modelling, 35 (4), 1810–1819. https://doi.org/10.1016/j.apm.2010.10.011

- Ramasubbu, N., Shang, J., May, J. H., Tjader, Y., Vargas, L. (2019). Task Interdependence and Firm Performance in Outsourced Service Operations. Manufacturing & Service Operations Management, 21 (3), 658–673. https://doi.org/10.1287/msom.2018.0716

- Reynard, P. C. (1998). Manufacturing Strategies in the Eighteenth Century: Subcontracting for Growth among Papermakers in the Auvergne. The Journal of Economic History, 58 (1), 155–182. https://doi.org/10.1017/s0022050700019926

- Rouhani, S., Pishvaee, M. S., Zarrinpoor, N. (2021). A fuzzy optimization approach to strategic organ transplantation network design problem: A real case study. Decision Science Letters, 10 (3), 195–216. https://doi.org/10.5267/j.dsl.2021.5.001

- Sung, P.-C., Lai, C.-M., Wang, Y., Chiu, Y.-S. P. (2022). Minimization of multiproduct fabrication cost featuring rework, commonality, external provider, and postponement. Uncertain Supply Chain Management, 10 (2), 353–364. https://doi.org/10.5267/j.uscm.2022.1.003

- Waiyawuththanapoom, P., Jermsittiparsert, K. (2022). The role of sustainable HRM in supply chain, profitability and resource utilization. Uncertain Supply Chain Management, 10 (2), 365–374. https://doi.org/10.5267/j.uscm.2022.1.002

- Youssef, A. M. A., ElMaraghy, H. A. (2008). Performance analysis of manufacturing systems composed of modular machines using the universal generating function. Journal of Manufacturing Systems, 27 (2), 55–69. https://doi.org/10.1016/j.jmsy.2008.07.003

- Zhu, S. X. (2015). Dynamic replenishment from two sources with different yields, costs, and leadtimes. International Journal of Production Economics, 165, 79–89. https://doi.org/10.1016/j.ijpe.2015.03.026

- Chen, W., Li, W., Wu, J., Wang, R., Liu, W., Xu, F. (2024). Fabrication of superior conductive composite yarn with 3D continuous CNT/WPU structure for high-performance stretchable heater and sensor. Composites Part A: Applied Science and Manufacturing, 185, 108289. https://doi.org/10.1016/j.compositesa.2024.108289

- Ramakrishna, Y., Alzoubi, H. (2022). Empirical Investigation of Mediating Role of Six Sigma Approach in Rationalizing the COQ in Service Organizations. Operations and Supply Chain Management: An International Journal, 15 (1), 122–135. https://doi.org/10.31387/oscm0480335

- Rizki, A. F., Augustine, Y. (2022). Green supply chain management practices: direct effects sustainability performance. Technium Social Sciences Journal, 28, 389–407. https://doi.org/10.47577/tssj.v28i1.5795

- Yassin, N. (2022). Development and Implementation of Quality Assurance According to GMP Guidelines in Lebanese Pharmaceutical Companies. Technium Social Sciences Journal, 37, 324–340. https://doi.org/10.47577/tssj.v37i1.7605

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Wirda Novarika, Sony Bahagia Sinaga, Satria Yudha Prayogi

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.