Identifying the effect of subgrade layer thickness of soil stabilized with waste foundry sand and fly ash on bearing capacity

DOI:

https://doi.org/10.15587/1729-4061.2024.306754Keywords:

subgrade, bearing capacity, stabilization, foundry sand, fly ash, plate load test, footingAbstract

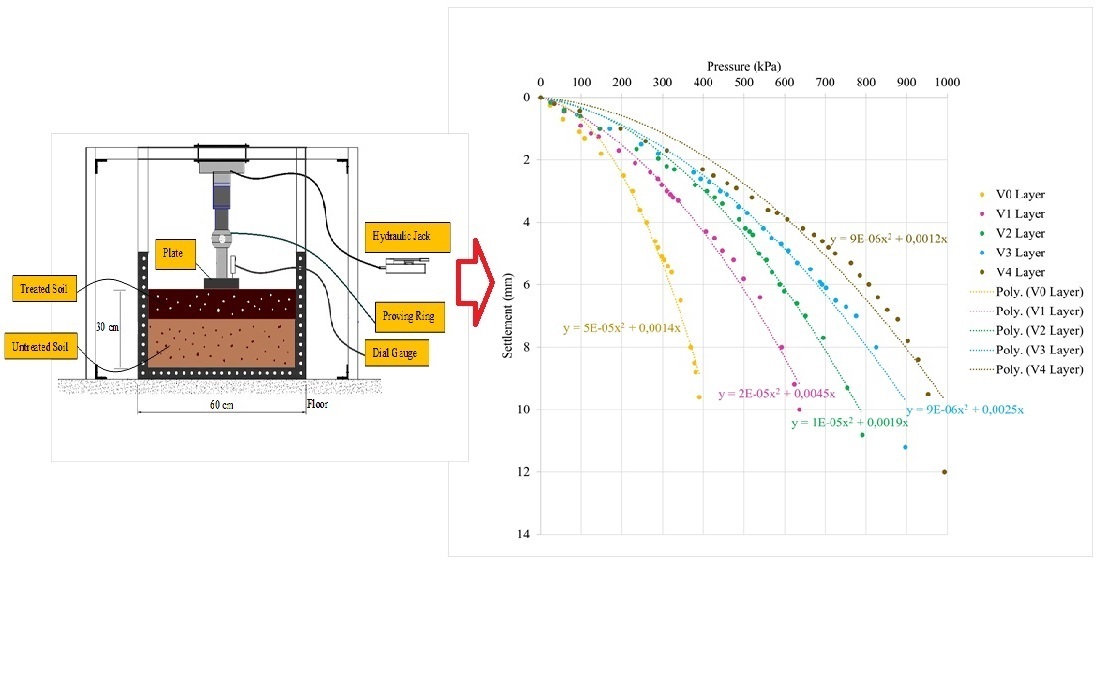

The issue of subgrade soil often involves unstable soil properties, such as low bearing capacity, susceptibility to expansion and shrinkage, and vulnerability to erosion and deformation due to traffic loads and weather conditions. Unstable subgrade soil can cause various infrastructure problems, including cracks, settlement, and damage to road surfaces. Therefore, stabilizing subgrade soil is an important step to ensure the reliability and longevity of highways. One effective and sustainable method for subgrade soil stabilization is by utilizing local waste materials. The use of local waste materials such as fly ash (FA) and waste foundry sand (WFS) not only improves the physical and mechanical properties of the soil but also helps reduce environmental impact by repurposing pollutants. This study aims to analyze the effect of the thickness of subgrade layers stabilized with FA and WFS on bearing capacity. The initial stage includes examining the physical and mechanical properties of natural soil and soil stabilized with FA and WFS. The waste content used is 9 % FA and 15 % WFS by dry weight of the soil. Subgrade modeling was conducted using a steel box measuring 60×60×60 cm with a soil thickness of 30 cm. Load testing was carried out on 5 layer variants that had undergone 4 days of curing. The study results found that the ultimate bearing capacity (qult) of 890 kPa was produced by the V4 layer, which is a subgrade with a 30 cm thick layer of soil stabilized with FA and WFS at a settlement of 6 mm. The bearing capacity ratio of 2.87 means that the subgrade with a 30 cm thick layer of soil stabilized with FA and WFS experienced an improvement in bearing capacity of 2.87 times that of the subgrade with untreated soil material. The results obtained can be applied in practice to the local geotechnical conditions of the project site in West Java, including natural soil properties and seasonal changes

Supporting Agency

- The authors would like to thank the head and staff of the Research and Community Service Institute (LPPM) of Universitas Brawijaya, as well as the Ministry of Education, Culture, Research and Technology of the Republic of Indonesia, General of Higher Education (DRTPM), Ministry of Education, Culture, Research and Technology of the Republic of Indonesia for their support and funding under the Doctoral Dissertation Research Grant (PDD) scheme for Fiscal Year 2024.

References

- Gupta, D., Kumar, A. (2017). Stabilized soil incorporating combinations of rice husk ash, pond ash and cement. Geomechanics and Engineering, 12 (1), 85–109. https://doi.org/10.12989/gae.2017.12.1.085

- Darmiyanti, L., Munawir, A., Rachmansyah, A., Zaika, Y., Andi Suryo, E. (2023). Identification of the influence of electrokinetic soil improvement on the microstructure, physical and mechanical properties of expansive soil. Eastern-European Journal of Enterprise Technologies, 6 (6 (126)), 41–50. https://doi.org/10.15587/1729-4061.2023.290234

- Zhang, Y., Sappinen, T., Korkiala-Tanttu, L., Vilenius, M., Juuti, E. (2021). Investigations into stabilized waste foundry sand for applications in pavement structures. Resources, Conservation and Recycling, 170, 105585. https://doi.org/10.1016/j.resconrec.2021.105585

- Sharma, A. K., Sivapullaiah, P. V. (2016). Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils and Foundations, 56 (2), 205–212. https://doi.org/10.1016/j.sandf.2016.02.004

- Mostafa, A. E. A., Eisa, M., Ibrahim, M. F. (2024). Effect of stabilizing subgrade layer using various additives on the flexible pavement design. Innovative Infrastructure Solutions, 9 (5). https://doi.org/10.1007/s41062-024-01430-8

- Ardah, A., Chen, Q., Abu-Farsakh, M. (2017). Evaluating the performance of very weak subgrade soils treated/stabilized with cementitious materials for sustainable pavements. Transportation Geotechnics, 11, 107–119. https://doi.org/10.1016/j.trgeo.2017.05.002

- Gunarti, A. S. S., Zaika, Y., Munawir, A., Suryo, E. A., Harimurti, H. (2023). Identifying the microstructure and mechanical properties of expansive soil stabilized using fly ash and waste foundry sand. Eastern-European Journal of Enterprise Technologies, 6 (6 (126)), 31–40. https://doi.org/10.15587/1729-4061.2023.286991

- Malik, Z. B., Alshameri, B., Jamil, S. M., Umar, D. (2021). Experimental and Numerical Modeling of Bearing Capacity of Foundations on Soft Clay Stabilized with Granular Material. International Journal of Geosynthetics and Ground Engineering, 7 (4). https://doi.org/10.1007/s40891-021-00334-2

- Sharma, R. K., Kumar, A. (2013). Compaction and Sub-grade Characteristics of Clayey Soil Mixed with Foundry Sand and Fly Ash. International Journal of Engineering Research & Technology (IJERT), 2 (10), 1504–1509. Available at: https://www.ijert.org/research/compaction-and-sub-grade-characteristics-of-clayey-soil-mixed-with-foundry-sand-and-fly-ash-IJERTV2IS100572.pdf

- Zimar, Z., Robert, D., Zhou, A., Giustozzi, F., Setunge, S., Kodikara, J. (2022). Application of coal fly ash in pavement subgrade stabilisation: A review. Journal of Environmental Management, 312, 114926. https://doi.org/10.1016/j.jenvman.2022.114926

- Kumar, A., Parihar, A. (2023). Experimental study on waste foundry sand as partial replacement of retaining wall backfill. Construction and Building Materials, 402, 132947. https://doi.org/10.1016/j.conbuildmat.2023.132947

- Arora, S., Kumar, A. (2019). Bearing Capacity of Square Footing Resting on Fibre-Reinforced Pond Ash Overlying Soft Clay. International Journal of Geosynthetics and Ground Engineering, 5 (1). https://doi.org/10.1007/s40891-019-0155-0

- Obrzud, R. F., Truty, A. (2018). The hardening soil model – a practical guidebook. Z_soil. Available at: http://www.zsoil.com/zsoil_manual_2018/Rep-HS-model.pdf

- D 1194-94. Standard Test Method for Bearing Capacity of Soil for Static Load and Spread Footings. ASTM.

- Chen, Q. (2007). An experimental study on characteristics and behavior of reinforced soil foundation. https://doi.org/10.31390/gradschool_dissertations.3361

- Li, Y., Su, L., Ling, X., Wang, J., Yang, Y. (2018). Model Studies on Load-Settlement Characteristics of Coarse-Grained Soil Treated with Geofiber and Cement. Polymers, 10 (6), 621. https://doi.org/10.3390/polym10060621

- Waruwu, A., Paulus Dwi Surya Emili Yanto, Rika Deni Susanti, Syukurman Harefa (2022). Study bearing capacity of subgrade using combination bamboo grid and stabilized soil. Journal of Infrastructure Planning and Engineering (JIPE), 1 (2), 87–92. https://doi.org/10.22225/jipe.1.2.2022.87-92

- Consoli, N. C., Rosa, A. D., Saldanha, R. B. (2011). Variables Governing Strength of Compacted Soil–Fly Ash–Lime Mixtures. Journal of Materials in Civil Engineering, 23 (4), 432–440. https://doi.org/10.1061/(asce)mt.1943-5533.0000186

- Barman, D., Dash, S. K. (2022). Stabilization of expansive soils using chemical additives: A review. Journal of Rock Mechanics and Geotechnical Engineering, 14 (4), 1319–1342. https://doi.org/10.1016/j.jrmge.2022.02.011

- Dayioglu, M., Cetin, B., Nam, S. (2017). Stabilization of expansive Belle Fourche shale clay with different chemical additives. Applied Clay Science, 146, 56–69. https://doi.org/10.1016/j.clay.2017.05.033

- Sithole, N. T., Tsotetsi, N. T., Mashifana, T., Sillanpää, M. (2022). Alternative cleaner production of sustainable concrete from waste foundry sand and slag. Journal of Cleaner Production, 336, 130399. https://doi.org/10.1016/j.jclepro.2022.130399

- Kumar, P., Paliwal, M. C., Jain. A. K. (2016). Stabilization Of Sub Grade Soil By Using Foundry Sand Waste. International journal of engineering sciences & research technology, 5 (9). http://dx.doi.org/10.5281/zenodo.154193

- Bose, B. (2012). Geo-engineering properties of expansive soil stabilized with fly ash. Electronic Journal of Geotechnical Engineering, 17 (1), 1339–1353.

- Gunarti, A. S. S., Zaika, Y., Kuntoro, S. A., Munawir, A., Suryo, E. A., Harimurti (2024). Improvement of the Bearing Capacity and Swelling of Ciampel Expansive Soil using Waste Foundry Sand. E3S Web of Conferences, 500, 03001. https://doi.org/10.1051/e3sconf/202450003001

- Consoli, N. C., Rosa, F. D., Fonini, A. (2009). Plate Load Tests on Cemented Soil Layers Overlaying Weaker Soil. Journal of Geotechnical and Geoenvironmental Engineering, 135 (12), 1846–1856. https://doi.org/10.1061/(asce)gt.1943-5606.0000158

- Abhiram, K., Kumar, M. H. (2020). Ultimate Bearing Capacity of Stabilized Soil in Pavements. International Journal of Innovative Technology and Exploring Engineering, 9 (5), 2349–2351. https://doi.org/10.35940/ijitee.d1807.039520

- Umum, K. P., Marga, D. J. B. (2013). Manual Desain Perkerasan Jalan. Jakarta: Binamarga.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anita Setyowati Srie Gunarti, Yulvi Zaika, As’ad Munawir, Eko Andi Suryo, Harimurti Harimurti

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.