Identification of the energy parameters of an electrohydroimpulse plant for the production of valuable components from organic raw materials

DOI:

https://doi.org/10.15587/1729-4061.2024.306787Keywords:

organic waste, bone mass, temperature, bone, spark discharge, energy parameters, secondary resource, recyclingAbstract

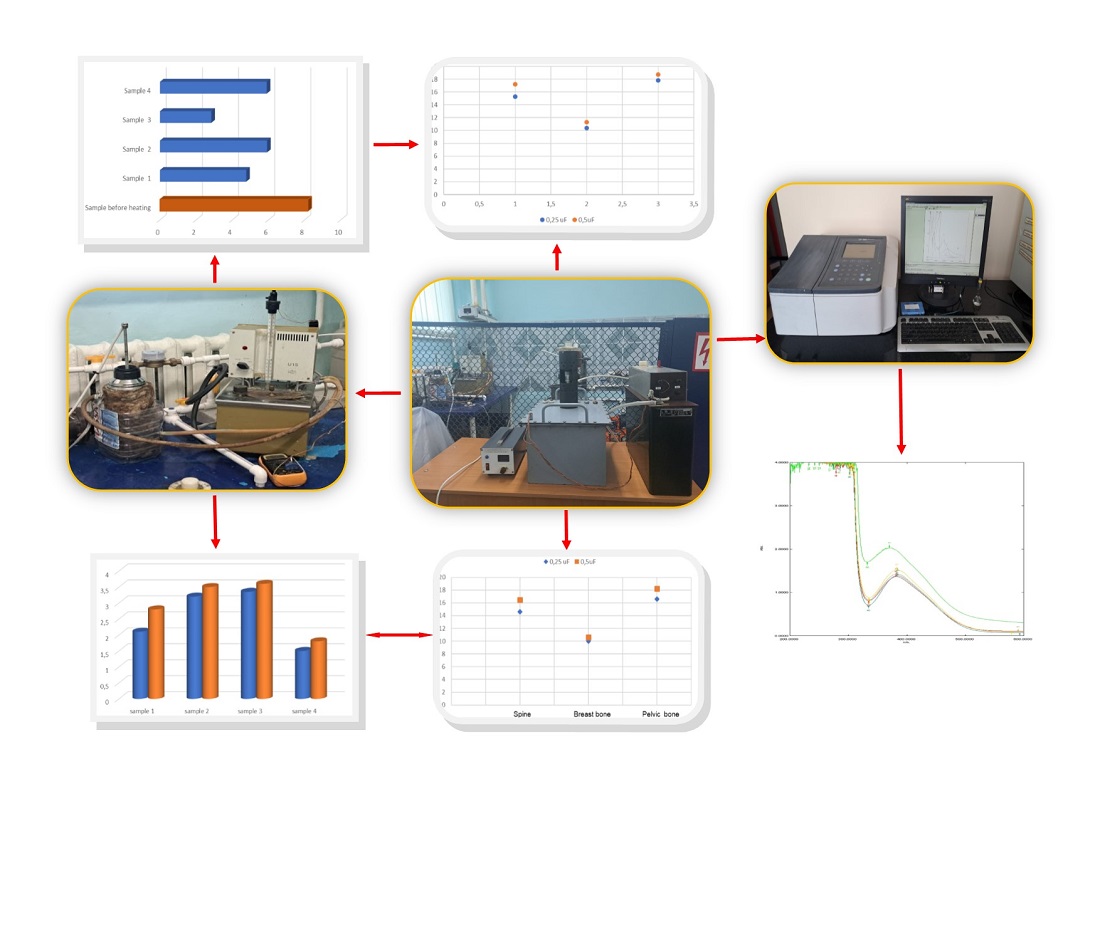

The paper presents the results of experimental studies on the developed bone degreasing stand. The object of the study is the production of valuable components from organic raw materials.

Fractions of cattle crushed to the size of 2.5 mm, 5.2 mm and 10.5 mm were used to identify the effective mode of operation of an electrohydroimpulse installation.

Physical and chemical methods of fat extraction are currently not relevant from the point of view of economy, due to environmental damage and labor intensity. In this regard, new effective methods of extracting fat from bone mass are needed. Therefore, the proposed method of extracting fat by spark discharge is an actual and alternative method for today.

During the study, an acceptable temperature regime for fat production was obtained. Next, a laboratory stand was assembled, with which you can degrease the bone mass without changing the properties of fat.

Experimental studies show that with an increase in the capacity of the capacitor bank in energy storage devices and the length of the discharge gap, the bone degreasing process becomes more efficient. During the study, it was found that at a liquid temperature of 38 °C and a pulse voltage of 25 kV on a switching device of an electrohydroimpulse installation, the degree of fat extraction increases without destroying the morphological structure of bone mass.

Using the hexane extraction reaction, we determined the efficiency of fat extraction at a temperature of 38 °C, at which the fat mass from the bones is effectively broken down, and using the UV-1800 spectrophotometer, we determined the amount of protein in the bones before and after treatment.

The study also showed that with a capacitor bank capacity of 0.5 uF, crushed to a fraction of 10.5 mm of pelvic bone, the separated fat is 18.7 %, and with constant grinding of the capacitor bank to a fraction of 2.5 mm – 19.4 %

References

- Belova, M. V. (2013). Technological equipment for heat treatment of agricultural raw materials. Bulletin of the I. Ya. Yakovlev Chuvash State Pedagogical University, 2 (78), 12–15.

- Kumar, S., Agarwal, N., Raghav, P. K. (2016). Pulsed electric field processing of foods-a review. International Journal of Engineering Research and Modern Education (IJERME), 1 (1). Available at: https://www.researchgate.net/publication/331298944_PULSED_ELECTRIC_FIELD_PROCESSING_OF_FOODS-A_REVIEW

- Arai, S., Morinaga, Y., Yoshikawa, T., Ichiishi, E., Kiso, Y., Yamazaki, M. et al. (2002). Recent Trends in Functional Food Science and the Industry in Japan. Bioscience, Biotechnology, and Biochemistry, 66 (10), 2017–2029. https://doi.org/10.1271/bbb.66.2017

- Lee, J.-R., Jalani, J. C., Arshad, Z. I. M., dos Santos, J. C. S., Mudalip, S. K. A., Shaarani, S. M., Sulaiman, S. Z. (2023). One-Factor-at-a-Time (OFAT) Optimization of Victoria Blue R Dye Biodegradation by Pineapple Waste Garbage Enzymes. Journal of Advanced Research in Applied Sciences and Engineering Technology, 35 (2), 1–10. https://doi.org/10.37934/araset.35.2.110

- Sensoy, I., Sastry, S. K. (2004). Extraction Using Moderate Electric Fields. Journal of Food Science, 69 (1). https://doi.org/10.1111/j.1365-2621.2004.tb17861.x

- Kasub, V. T., Orobinskaya, V. N., Pisarenko, O. N. (2013). Advantages of modern non- thermal technologies in the processing of organic raw materials. Modern science and innovation, 3, 82–93.

- Barba, F. J., Parniakov, O., Pereira, S. A., Wiktor, A., Grimi, N., Boussetta, N. et al. (2015). Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Research International, 77, 773–798. https://doi.org/10.1016/j.foodres.2015.09.015

- Wiktor, A., Schulz, M., Voigt, E., Witrowa-Rajchert, D., Knorr, D. (2015). The effect of pulsed electric field treatment on immersion freezing, thawing and selected properties of apple tissue. Journal of Food Engineering, 146, 8–16. https://doi.org/10.1016/j.jfoodeng.2014.08.013

- Segovia, F. J., Luengo, E., Corral-Pérez, J. J., Raso, J., Almajano, M. P. (2015). Improvements in the aqueous extraction of polyphenols from borage (Borago officinalis L.) leaves by pulsed electric fields: Pulsed electric fields (PEF) applications. Industrial Crops and Products, 65, 390–396. https://doi.org/10.1016/j.indcrop.2014.11.010

- Segovia, F., Lupo, B., Peiró, S., Gordon, M., Almajano, M. (2014). Extraction of Antioxidants from Borage (Borago officinalis L.) Leaves – Optimization by Response Surface Method and Application in Oil-in-Water Emulsions. Antioxidants, 3 (2), 339–357. https://doi.org/10.3390/antiox3020339

- Wu, L., Li, L., Chen, S., Wang, L., Lin, X. (2020). Deep eutectic solvent-based ultrasonic-assisted extraction of phenolic compounds from Moringa oleifera L. leaves: Optimization, comparison and antioxidant activity. Separation and Purification Technology, 247, 117014. https://doi.org/10.1016/j.seppur.2020.117014

- Luengo, E., Condón-Abanto, S., Álvarez, I., Raso, J. (2014). Effect of Pulsed Electric Field Treatments on Permeabilization and Extraction of Pigments from Chlorella vulgaris. The Journal of Membrane Biology, 247 (12), 1269–1277. https://doi.org/10.1007/s00232-014-9688-2

- Ade-Omowaye, B. I. O., Angersbach, A., Taiwo, K. A., Knorr, D. (2001). Use of pulsed electric field pre-treatment to improve dehydration characteristics of plant based foods. Trends in Food Science & Technology, 12 (8), 285–295. https://doi.org/10.1016/s0924-2244(01)00095-4

- Ershova, I. G., Sorokina, M. G., Mikhailova, O. V. (2013). Technology of processing of fat- containing raw materials. Natural and Technical Sciences, Bulletin of the I. Ya. Yakovlev ChSPU, 4 (80), 83–86.

- Kurytnik, I. P., Nussupbekov, B. R., Karabekova, D. Zh., Khassenov, A. K., Kazhikenova, A. Sh. (2018). Investigation of a crushing and grinding unit of an electropulse installation. Archives of Foundry Engineering, 18 (1). https://doi.org/10.24425/118812

- Nusupbekov, B. R., Stoev, M., Khasenov, A. K., Abisheva, A. K., Tagirov, E. O. (2014). Development of electrical technologies for the extraction of organic substances from raw materials. Bulletin of the Karaganda University “Physics Series”, 3 (75), 63–67.

- Kusaiynov, K., Shuyushbayeva, N. N., Nusupbekov, B. R., Turdybekov, K. M., Shaimerdenova, K. M., Akhmadiev, B. A. (2015). Microstructural analysis of the positive electrode of electrohydraulic drill. Technical Physics, 60 (12), 1884–1886. https://doi.org/10.1134/s1063784215120105

- Karabekova, D. Zh., Kissabekova, P. A., Nussupbekov, B. R., Khassenov, A. K. (2021). Analysis of the Insulation State of Underground Pipelines in the Heating Network. Thermal Engineering, 68 (10), 802–805. https://doi.org/10.1134/s0040601521100013

- Khassenov, A., Bulkairova, G., Karabekova, D., Bolatbekova, M., Alpyssova, G., Kudussov, A., Kissabekova, P. (2024). Identification of the impact of electric pulse action on the disintegration of a natural mineral. Eastern-European Journal of Enterprise Technologies, 1 (1 (127)), 54–59. https://doi.org/10.15587/1729-4061.2024.289556

- Nussupbekov, B. R., Dyusenbayeva, M. S. (2023). Processing of organic waste by electrohydroimpulse method. Bulletin of the Karaganda University “Physics Series,” 111 (3), 156–162. https://doi.org/10.31489/2023ph3/156-162

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Gulnaz Kartbayeva, Мoldir Duisenbayeva, Bekbolat Nussupbekov, Elmira Mussenova, Zhanaidar Smagulov, Alikhan Kurmanaliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.