Effect of box beam wall thickness on the stiffness of the camphor wood timber bridge truss

DOI:

https://doi.org/10.15587/1729-4061.2024.309345Keywords:

wooden truss bridge, box beam, peak load, stiffnessAbstract

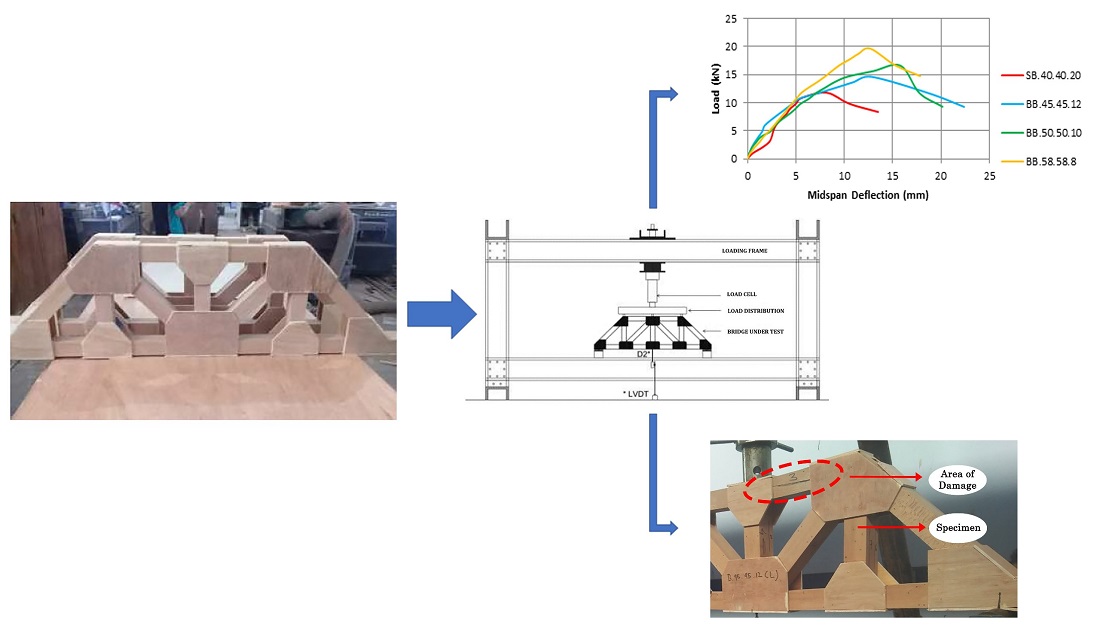

Bridges are vital for community development, and wood is a primary material due to its environmental benefits. However, wood’s moisture absorption can cause swelling and shrinkage, and low-density wood tends to have lower strength. The moment of inertia of a box beam is related to wall thickness and stiffness. Insufficient wall thickness can lead to plastic retention before peak load, reducing structural integrity. Thin walls can cause buckling under compressive loads, leading to failure. Truss bridge failures can also result from design errors. This study aims to analyze the effect of box beam wall thickness on the stiffness of camphor wood timber bridge trusses. Camphor wood with a cross-sectional area of 1,600 mm2 was used, with box beams of dimensions 45×45 mm (12 mm wall), 50×50 mm (10 mm wall), 58×58 mm (8 mm wall), and a solid beam of 40×40 mm (20 mm wall). Physical tests showed the wood’s specific gravity at 0.506 g/cm3 and moisture content at 12.47 %. The highest peak load was 19.613 kN for the BB.58.58.8 variation, which also had the greatest stiffness at 3.502 kN/mm. The BB.58.58.5 variation had the largest moment of inertia at 683,733 mm4 compared to the solid beam SB.40.40.20 at 213,333 mm4. The BB.45.45.12 sample had a t/D ratio 1.93 times larger than BB.58.58.8, indicating a more flexible structure with lower stiffness. This is confirmed by experimental results, showing that BB.45.45.12 had a stiffness 1.73 times lower than BB.58.58.8. Theoretical calculations also showed that BB.45.45.12 had a stiffness 2.03 times smaller than BB.58.58.8. Thus, the t/D ratio is inversely proportional to stiffness. This research contributes valuable insights for developing engineered wood products in construction and bridge design, particularly for village bridges in Indonesia

Supporting Agency

- We would like to thank the Indonesian Ministry of Research, Technology and Higher Education for providing financial support in the DRTPM Research Program for Beginner Lecturers (PPDP), thus helping the completion of this research.

References

- Hadinata, C., Wiguna, A. C. (2016). Perencanaan Jembatan Rangka Baja Air Pedado Kelurahan Kramasan Kecamatan Kertapati Palembang Provinsi Sumatera Selatan. Politeknik Negeri Sriwijaya Palembang.

- Atmojo, B. T., Huda, M., Siswoyo, S. (2018). Perencanaan ulang struktur jembatan sembayat ii gresik menggunakan balok induk beton prategang “V” pada bentang KE-3. Axial: Jurnal Rekayasa Dan Manajemen Konstruksi, 6 (1), 33. https://doi.org/10.30742/axial.v6i1.473

- Marga, D. B. (2023). Jumlah Jembatan Nasional. Jakarta.

- Setiadi, M. R., Agustine, D., Abdillah, H. (2021). Pengujian Kayu Balsa Untuk Struktur Jembatan. Jurnal Ilmiah Fakultas Teknik, 2 (1), 14–21.

- Suryoatmono, B. (2013). Kayu Rekayasa Sebagai Masa Depan Struktur Kayu Indonesia. In the 2nd Indonesian Structural Engineering And Materials Symposium. Bandung: Jurusan Teknik Sipil Universitas Parahyangan.

- Departemen Pekerjaan Umum, Peraturan Konstruksi Kayu Indonesia (PPKI) (1961). Bandung: DITJEN Cipta Karya.

- Tjondro, J. A., Fachmi (2009). Kuat Lentur Balok Penampang Tersusun Box dari Papan Kayu Sengon. In Simposium Nasional Peningkatan Peran FTHH dalam Penelitian dan Pengembangan IPTEK untuk Menunjang Revitalisasi Hasil Hutan Indonesia. Bogor.

- Development and evaluation of composite materials (1965). Wear, 8 (4), 324. https://doi.org/10.1016/0043-1648(65)90045-1

- Karyadi, Dewi, S. M., Soehardjono, A. (2013). Experimental Investigation on Characteristics of Mechanics of Box-Section Beam Made Of Sliced-Laminated Dendrocalamus Asper under Torsion. International Journal of Engineering Research and Applications (IJERA), 3 (4), 2614–2619. https://www.researchgate.net/publication/320707368

- Karyadi, Susanto, P. B. (2017). Mechanical characteristics of box-section beam made of sliced-laminated Asian bamboo (Dendrocalamus asper) in bending failure mode under transversal load. AIP Conference Proceedings. https://doi.org/10.1063/1.5003545

- Wijaya, H. S., Erizaldy, A. (2020). Kajian Desain Jembatan Sederhana Tipe Hollow Section Truss (HST) dari Material Kayu Kamper. Jurnal Fondasi, 9 (2), 215. https://doi.org/10.36055/jft.v9i2.8522

- Ammayappan, L. (2013). Application of enzyme on woolen products for its value addition: An overview. Journal of Textile and Apparel, Technology and Management, 8 (3).

- Zhang, G., Liu, Y., Liu, J., Lan, S., Yang, J. (2022). Causes and statistical characteristics of bridge failures: A review. Journal of Traffic and Transportation Engineering (English Edition), 9 (3), 388–406. https://doi.org/10.1016/j.jtte.2021.12.003

- Lehmann, S. (2013). Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions. Sustainable Cities and Society, 6, 57–67. https://doi.org/10.1016/j.scs.2012.08.004

- Spesifikasi desain untuk konstruksi kayu SNI 7973-2013. Available at: https://wiryanto.blog/wp-content/uploads/2017/09/sni-7973-2013-spesifikasi-disain-untuk-konstruksi-kayu-v-3-0.pdf

- Wijaya, H. S., Oktaviastuti, B. (2017). Perbandingan kekakuan puntir (torsional stiffness) antara balok kayu kamper berpenampang hollow (box beam) dan solid. Jurnal Reka Buana, 2 (2). Available at: https://jurnal.unitri.ac.id/index.php/rekabuana/article/view/730

- Wijaya, H. S., Oktaviastuti, B. (2018). Perbandingan Tegangan Aksial Antara Jembatan Rangka Kayu Box Beam Section dan Konvensional Dari Kayu Kamper. Pros. Semin. Nas. Teknol. Ind. Lingkung. dan Infrastruktur (SENTIKUIN). Available at: https://pro.unitri.ac.id/index.php/sentikuin/article/view/44

- Taghiyari, H. R., Ghofrani, M., Ghamsari, F. A. (2017). Effects of adhesive and loading directions on the load-carrying capacity of V-nails. Maderas. Ciencia y Tecnología, ahead. https://doi.org/10.4067/s0718-221x2017005000010

- Fernandes, C., Gaspar, M., Pires, J., Alves, A., Simões, R., Rodrigues, J. et al. (2017). Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal. IForest - Biogeosciences and Forestry, 10 (4), 669–679. https://doi.org/10.3832/ifor2254-010

- Kaya, T. G., Karagüler, M. E. (2017). The Effect of Relative Humidity and Moisture to the Durability of Spruce and Laminated Timber. A/Z : ITU Journal of Faculty of Architecture, 14 (1), 103–110. https://doi.org/10.5505/itujfa.2017.18480

- Shanmugam, N. E., Liew, J. Y. R., Lee, S. L. (1989). Thin‐Walled Steel Box Columns under Biaxial Loading. Journal of Structural Engineering, 115 (11), 2706–2726. https://doi.org/10.1061/(asce)0733-9445(1989)115:11(2706)

- Sharma, I., Singh, G. J. (2022). Effect of Outstanding Flanges on Stress Concentration in Box Beam. Civil Engineering and Architecture, 10 (7), 3071–3082. https://doi.org/10.13189/cea.2022.100720

- Dupen, B. (2016). Applied Strength of Materials for Engineering Technology. Purdue Univ. Available at: https://core.ac.uk/download/pdf/47233878.pdf

- Alhawamdeh, M., Alajarmeh, O., Aravinthan, T., Shelley, T., Schubel, P., Mohammed, A., Zeng, X. (2021). Review on Local Buckling of Hollow Box FRP Profiles in Civil Structural Applications. Polymers, 13 (23), 4159. https://doi.org/10.3390/polym13234159

- Erdal, F., Saka, M. P. (2013). Ultimate load carrying capacity of optimally designed steel cellular beams. Journal of Constructional Steel Research, 80, 355–368. https://doi.org/10.1016/j.jcsr.2012.10.007

- Calderoni, C., De Matteis, G., Giubileo, C., Mazzolani, F. M. (2006). Flexural and shear behaviour of ancient wooden beams: Experimental and theoretical evaluation. Engineering Structures, 28 (5), 729–744. https://doi.org/10.1016/j.engstruct.2005.09.027

- Wasef, S., Wood, R., El Merghani, S., Ikram, S., Curtis, C., Holland, B. et al. (2015). Radiocarbon dating of Sacred Ibis mummies from ancient Egypt. Journal of Archaeological Science: Reports, 4, 355–361. https://doi.org/10.1016/j.jasrep.2015.09.020

- Zhou, Y., Yan, W. (2015). Conservation and applications of camphor tree (Cinnamomum camphora) in China: ethnobotany and genetic resources. Genetic Resources and Crop Evolution, 63 (6), 1049–1061. https://doi.org/10.1007/s10722-015-0300-0

- Supriyadi, B., Muntohar, A. S. (2007). Jembatan. Yogyakarta: Beta Offset.

- Pusat Penelitian dan Pengembangan Hasil Hutan (P3HH). Petunjuk Praktis Sifat-Sifat Dasar Jenis Kayu Indonesia: A Handbook of Selected Indonesian Wood Species. Indonesia: PT. Pusaka Semesta Persada. Available at: http://www.itto.int/files/user/pdf/publications/PD%20286%2004/pd286-04-6%20rev1(I)%20i.pdf

- Kusnindar, A. (2005). Karakteristik Mekanik Kayu Kamper Sebagai Bahan Konstruksi. J. Mektek, 7 (1), 41–47.

- Oka, G. (2009). Analisis rasio antara lebar dan tinggi balok terhadap perilaku lentur kayu kamper. Smartek, 7 (1), 24–31.

- Widyawati, R. (2009). Perbandingan Kekuatan Butt Joint dan Scraft Joint pada Kayu dengan Alat Sambung Perekat. Rekayasa, 13 (1), 77–87. Available at: https://media.neliti.com/media/publications/140086-ID-perbandingan-kekuatan-butt-joint-dan-sca.pdf

- Kirk, R. E., Othmer, D. F., Newburger, S. H. (1953). Encyclopedia of Chemical Technology. Journal of AOAC INTERNATIONAL, 36 (4), 1190a–11191. https://doi.org/10.1093/jaoac/36.4.1190a

- Lehringer, C., Gabriel, J. (2014). Review of Recent Research Activities on One-Component PUR-Adhesives for Engineered Wood Products. Materials and Joints in Timber Structures, 405–420. https://doi.org/10.1007/978-94-007-7811-5_37

- Athariqa, D., Oktapia, S. M., Dermawan, D. (2022). Urea-Formaldehid Konsentrat Sebagai Bahan Baku Resin Urea-Formaldehid. Jurnal Rekayasa Hijau, 6 (1), 11–21. https://doi.org/10.26760/jrh.v6i1.11-21

- Vargiu, S., Giovanni, S. S., Mazzoleni, G., Nistri, U. (1974). United States Pat. No. US3830783A. Process for the preparation of resins from urea, formaldehyde, methanol and formic acid using three stages. Available at: https://patents.google.com/patent/US3830783A/ja

- John, C. W. (2014). Research Design Pendekatan Kualititatif, Kuantitatif, dan Campuran. Yogyakarta.

- Sugiyono (2019). Metode Penelitian Pendidikan Pendekatan Kuantitatif, Kualitatif, dan R&D. Bandung.

- Chauf, K. A. (2012). The Effect of The End-Joint Applications To The Bending Strength and Flexure Behaviour of The Glulam Beam. INFRASTRUKTUR, 2 (1), 26–35.

- Koirala, R., Acharya, A., Chitrakar, S. (2021). Structural Optimization of Simple Span Bridge by Adding Truss Structure. Kathmandu University Journal of Science, Engineering and Technology, 15 (2). https://doi.org/10.3126/kuset.v15i2.63366

- Stanković, T., Štorga, M., Marjanović, D. (2012). Synthesis of Truss Structure Designs by NSGA-II and NodeSort Algorithm. Strojniški Vestnik – Journal of Mechanical Engineering, 58 (3), 203–212. https://doi.org/10.5545/sv-jme.2011.042

- Standar Nasional Indonesia, Badan Standarisasi Nasional. Indonesia: Spesifikasi Desain Untuk Konstruksi Kayu.

- Hirschmüller, S., Marte, R., Englberger, A. (2020). Applicability of finger jointing to circular laminated veneer hollow sections for temporary soil nailing. European Journal of Wood and Wood Products, 78 (5), 879–889. https://doi.org/10.1007/s00107-020-01577-y

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Handika Setya Wijaya, Blima Oktaviastuti, Fifi Damayanti, Yeni Sesti Ariningsih

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.