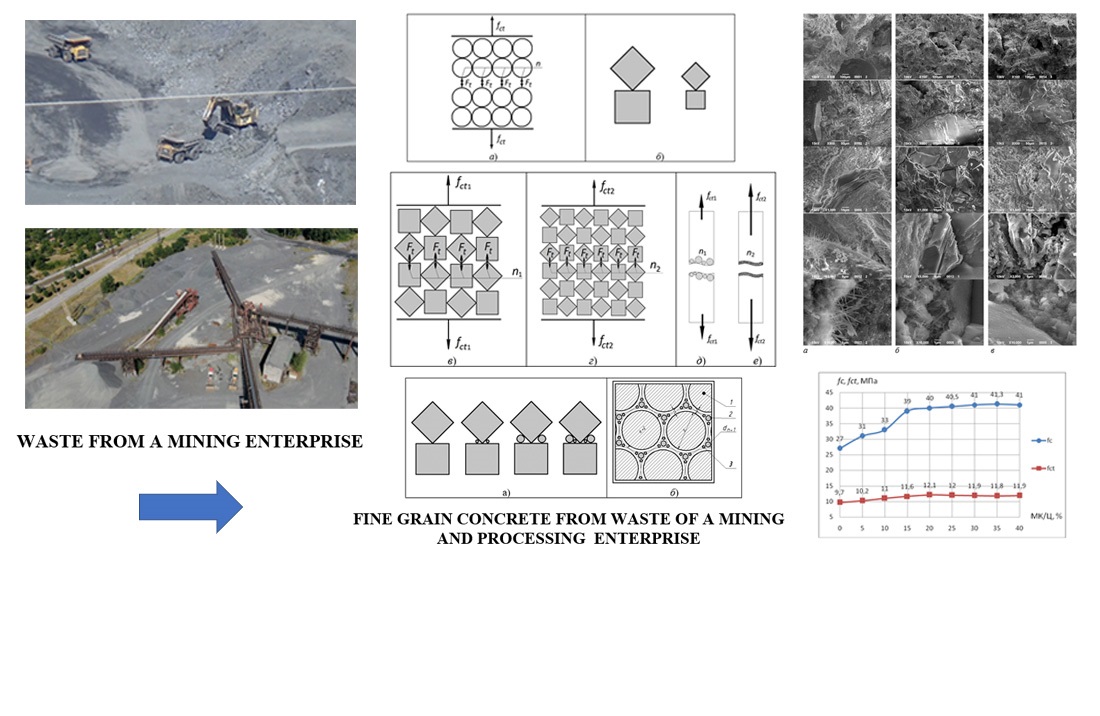

Developing the composition of fine-grained concrete from the waste of the mining and processing enterprise

DOI:

https://doi.org/10.15587/1729-4061.2024.310265Keywords:

fine-grained concrete, waste from mining and processing plants, hydration products, compressive strength, water resistanceAbstract

The object of this study is fine-grained concrete from the waste of mining and processing plants. These wastes are fine-grained dusty sands of polymineral composition. Their use as an aggregate for concrete is restrained by high water consumption, which does not make it possible to obtain sufficient strength for concrete. Therefore, the problem to be solved was the substantiation of the composition of fine-grained concrete from these wastes with mineral and chemical additives, which would ensure obtaining physical-mechanical and hydrophysical properties reasonable for the production of construction articles. The composition of fine-grained concrete from the waste at the Poltava Mining and Processing Plant and slag Portland cement in a ratio of 3:1 and additives of micro silica (15 % of the cement mass) and polycarboxylate superplasticizer (2 % of the cement mass) with W/C=0.5 was obtained. The compressive strength of this concrete reaches 40 MPa, which exceeds the strength of fine-grained concrete of a similar composition on natural fine-grained sand by 3 times. This is due to a greater degree of cement hydration, a greater number of formed hydration products, the presence of silica and quartz particles, a more uniform alternation of gel, silica particles, and crystal hydrates in the structure of cement stone. As a result, the structure contains a larger number of electro heterogeneous contacts between particles and grains that have negative (quartz, calcium hydro silicates) and positive (crystal hydrates of portlandite, hydro aluminates and calcium hydrosulfoaluminate) surface charges. This is what determines the achieved strength and water resistance of fine-grained concrete. The resulting composition of fine-grained concrete is recommended for the production of construction articles.

References

- Matyskova, K., Bilek, V., Prochazka, L., Hedlova, R., Hornakova, M. (2024). Replacement of Fine Aggregates in Fine-Grained Concrete by Waste Material from Cetris Boards Production. Defect and Diffusion Forum, 432, 31–38. https://doi.org/10.4028/p-smci67

- Anatolii, V., Ivan, B., Liubov, K., Zeljko, K., Iryna, G. (2021). Fine-grained Fiber Concrete on Mechanoactivated Portlandcement. Croatian Regional Development Journal, 2 (1), 41–49. https://doi.org/10.2478/crdj-2021-0007

- Shіshkina, A., Piskun, I. (2023). Formation of the strength of fine-grained concrete based on modified slag Portland cement. Eastern-European Journal of Enterprise Technologies, 5 (6 (125)), 74–81. https://doi.org/10.15587/1729-4061.2023.289929

- Sudhakar, A. J., Muthusubramanian, B. (2023). Influence of Basalt Fiber and Slag on the Moduli of Elasticity of Fine-Grained Concrete. Sustainable Innovations in Construction Management, 469–479. https://doi.org/10.1007/978-981-99-6233-4_43

- Nurbayeva, M. N., Aruova, L. B., Kalym, S. S., Toleubayeva, Sh. B., Urkinbayeva, Zh. I., Aukazhieva, Zh. M. et al. (2022). Influence of Fiber on the Strength Characteristics of Fine-Grained Concrete. Proceedings of 2021 4th International Conference on Civil Engineering and Architecture, 151–161. https://doi.org/10.1007/978-981-16-6932-3_13

- Betz, P., Curosu, V., Loehnert, S., Marx, S., Curbach, M. (2023). Classification of Multiaxial Behaviour of Fine-Grained Concrete for the Calibration of a Microplane Plasticity Model. Buildings, 13 (11), 2704. https://doi.org/10.3390/buildings13112704

- Diveiev, B. M., Konyk, C. I. (2016). Dynamichni vlastyvosti plastyn z funktsionalno hradientnykh materialiv pry zghyni. Visnyk Natsionalnoho universytetu «Lvivska politekhnika». Dynamika, mitsnist ta proektuvannia mashyn i pryladiv, 838, 29–36. Available at: http://nbuv.gov.ua/UJRN/VNULPDM_2016_838_7

- Plugin, A., Chaika, V., Musienko, S., Najafov, E. (2024). Extra fine-grained concrete from waste of mining concentration plant for construction products. Collection of Scientific Works of the Ukrainian State University of Railway Transport, 208, 79–91. https://doi.org/10.18664/1994-7852.208.2024.308196

- Babushkin, V. I., Plugin, A. A., Kostyuk, T. A., Matvienko, V. A. (1999). Vliyanie aktivnyh poverhnostnyh tsentrov na prochnost' svezheotformovannyh melkozernistyh betonov. Naukovyi visnyk budivnytstva, 5, 85–88.

- Vandalovskyi, A. H., Kazimahomedov, I. E., Chaika, V. M. (2011). Optymizatsiya struktury mikrobetonu. Naukovyi visnyk budivnytstva, 65, 153–160.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Plugin, Vitalii Chaika, Sergii Musyenko, Ping Wu, Zhenhua Ye

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.