Defining patterns in the intensification of hemp stalk retting processes

DOI:

https://doi.org/10.15587/1729-4061.2024.315058Keywords:

industrial hemp, harvesting technologies, retting, preparation time, fiber qualityAbstract

The object of this study is the technological operations of primary hemp stalk processing, factors that intensify the retting process, and stalk crushing.

The task addressed was the identification of technical and technological solutions that would enable intensification of the production processes for hemp retting.

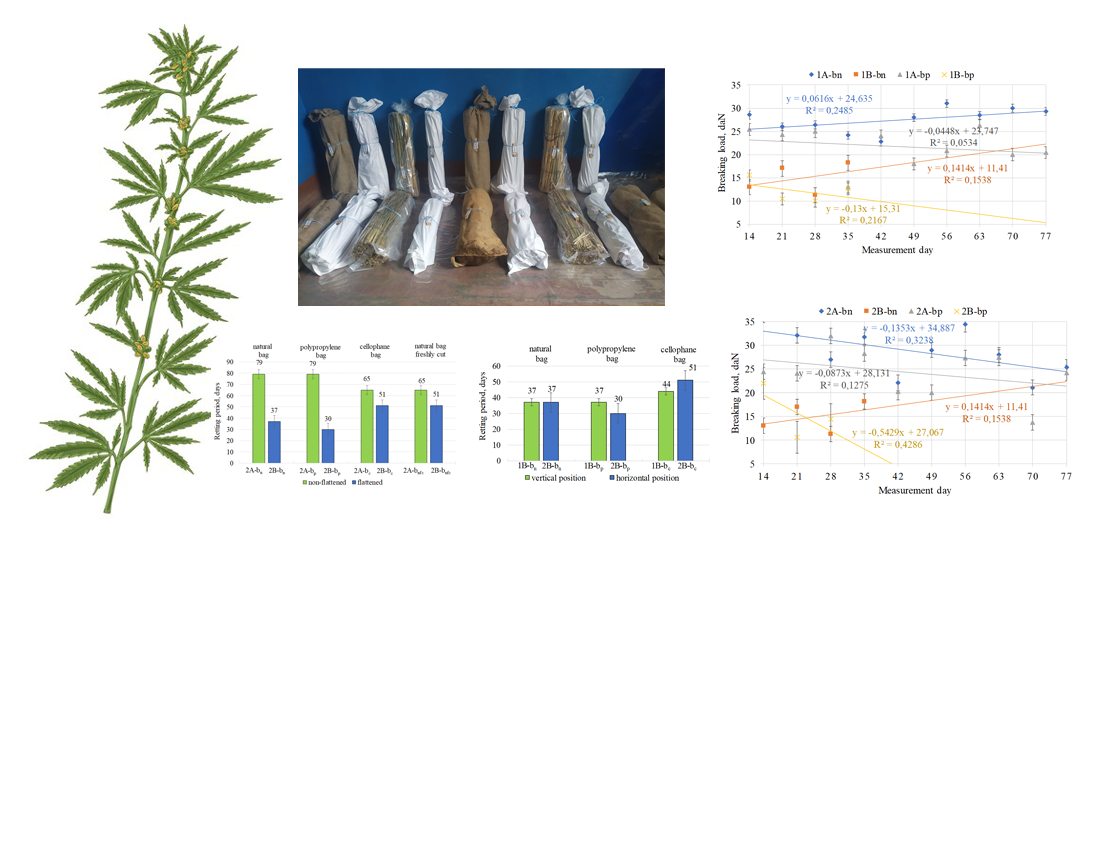

Based on the research results, it was established that placing the flattened stems in natural and polypropylene bags, compared to cellophane bags, accelerates the preparation time of retted stalks in a vertical position by 1.19 times, and in a horizontal position by 1.38 times. The retting time for horizontally placed crushed stalks with weekly moistening twice a week is 2.16 times shorter than for uncrushed ones.

It was determined that the process of crushing pre-prepared and cured stalks, whether in a vertical or horizontal position, allows for a significant reduction in retting period by 2.14 times, and for freshly cut stalks – by 1.27 times.

The intensity of the reflected light flux changed in the case of reaching the retting phase for unflattened stems with their vertical placement from the initial 32.0 lux to 18.0 lux. In flattened stems under the conditions of their vertical placement – from 50.7 to 16.3 lux, respectively. In the case of horizontally placed crushed stalks, the light intensity at the retting phase was 20.3 lux.

The lowest fiber breaking load value of 5.0 daN was established for the retted stalks obtained from freshly cut flattened stems in a vertical position, as well as in non-flattened stems in the vertical (7.0 daN) and horizontal (3.5 daN) positions

References

- Tkachenko, S. M., Mokher, Yu. V., Laiko, I. M., Zhuplatova, L. M., Vyrovets, V. H., Mishchenko, S. V., Kyrychenko, S. H. et al. (2021). Dovidnyk konopliara. Sumy: Ellada, 27.

- Small, E., Marcus, D. (2002). Hemp: A new crop with new uses for North America. Trends in new crops and new uses. Proceedings of the Fifth National Symposium, 284–326.

- Chursina, L., Tihosova, A., Bogdanova, O. (2020). Influence of processability of trust stem on the strength of hemp fibers. Commodity Bulletin, 1 (13), 65–74. https://doi.org/10.36910/6775-2310-5283-2020-13-06

- Sheichenko, V., Koropchenko, S., Horbenko, O., Skoriak, Y., Sheichenko, D. (2024). Results of research on factors intensifying hemp trust preparation processes. 23rd International Scientific Conference Engineering for Rural Development Proceedings. https://doi.org/10.22616/erdev.2024.23.tf050

- Lyalina, N., Yudicheva, O., Votchenikova, O., Berezovskiy, Y. (2020). Prognosis applications nonnarcotic hemp based on the criterial characteristics. Fibres and Textiles, 1, 35–41.

- Popa, L.-D., Zaica, A., Nedelcu, A., Zaica, A., Matei, G., Naie, M. et al. (2022). Considerations on hemp stalk harvesting using specialized equipment. INMATEH Agricultural Engineering, 51–59. https://doi.org/10.35633/inmateh-68-05

- Manea, D., Stroescu, G., Popa, L., Ionescu, A., Zaica, A. (2023). Management practices in industrial hemp harvesting and storage. INMATEH Agricultural Engineering, 69 (1), 520–526. https://doi.org/10.35633/inmateh-69-49

- Păun, A., Stroescu, G., Zaica, A., Ciupercă, R., Bogdanof, C. (2020). Analysis of the process of green hemp stalks sequential harvesting. E3S Web of Conferences, 180, 03026. https://doi.org/10.1051/e3sconf/202018003026

- Shen, C., Zhang, B., Huang, J., Tian, K., Liu, H., Li, X. et al. (2020). Research Status and Suggestions of Mechanical Harvesting Technology for High-Stalk Bast-Fiber Crops. International Agricultural Engineering Journal, 29 (2), 269–284.

- Sheychenko, V. O., Koropchenko, S. P., Dudnikov, I. A., Salo, Y. M., Skoryak, Yu. B. (2023). Technical and Technological Solutions for the Intensification of the Processing of Hemp Raw Materials. National Interagency Scientific and Technical Collection of Works. Design, Production and Exploitation of Agricultural Machines, 53, 85–93. https://doi.org/10.32515/2414-3820.2023.53.85-93

- Réquilé, S., Mazian, B., Grégoire, M., Musio, S., Gautreau, M., Nuez, L. et al. (2021). Exploring the dew retting feasibility of hemp in very contrasting European environments: Influence on the tensile mechanical properties of fibres and composites. Industrial Crops and Products, 164, 113337. https://doi.org/10.1016/j.indcrop.2021.113337

- Ventorino, V., Chouyia, F. E., Romano, I., Mori, M., Pepe, O. (2024). Water retting process with hemp pre-treatment: effect on the enzymatic activities and microbial populations dynamic. Applied Microbiology and Biotechnology, 108 (1). https://doi.org/10.1007/s00253-024-13300-5

- Sheichenko, V., Shevchuk, V., Dudnikov, I., Koropchenko, S., Dnes, V., Skoriak, Y., Skibchyk, V. (2022). Devising technologies for harvesting hemp with belt threshers. Eastern-European Journal of Enterprise Technologies, 1 (1 (115)), 67–75. https://doi.org/10.15587/1729-4061.2022.251126

- Angulu, M., Gusovius, H.-J. (2024). Retting of Bast Fiber Crops Like Hemp and Flax – A Review for Classification of Procedures. Fibers, 12 (3), 28. https://doi.org/10.3390/fib12030028

- Virovetc, V. G., Laiko, I. M., Kirichenko, G. I. (2007). Modern Hemp Collection As Not Primary Source of Selection Material. Selection, Production Technology and Primary Processing of Flax and Hemp, 4, 35–42.

- Duque Schumacher, A. G., Pequito, S., Pazour, J. (2020). Industrial hemp fiber: A sustainable and economical alternative to cotton. Journal of Cleaner Production, 268, 122180. https://doi.org/10.1016/j.jclepro.2020.122180

- Venturi, P., Amaducci, S., Amaducci, M. T., Venturi, G. (2007). Interaction Between Agronomic and Mechanical Factors for Fiber Crops Harvesting: Italian Results-Note II. Hemp. Journal of Natural Fibers, 4 (3), 83–97. https://doi.org/10.1300/j395v04n03_06

- Koropchenko, S. P., Mokher, Yu. V. (2018). Pidsumky naukovo-doslidnykh robit z mekhanichnoi pererobky konopel na pidpryiemstvakh maloho ta serednoho biznesu. Engineering sciences: development prospects in countries of Europe at the beginning of the third millennium. Vol. 2. Riga: Izdevnieciba "Baltija Publishing”, 112–137. Available at: https://www.researchgate.net/profile/Grigoriy-Kovalenko/publication/344882569_ENGINEERINGSCIENCES_DEVELOPMENTPROSPECTSINCOUNTRIESOFEUROPEATTHEBEGINNINGOFTHETHIRDMILLENNIUM/links/5f968fe7299bf1b53e45ea52/ENGINEERINGSCIENCES-DEVELOPMENTPROSPECTSINCOUNTRIESOFEUROPEATTHEBEGINNINGOFTHETHIRDMILLENNIUM.pdf

- Carus, M. (2017). The European hemp industry: Cultivation, processing and applications for fibres, shivs, seeds and flowers. European Industrial Hemp Association. Available at: http://eiha.org/media/2017/12/17-03_European_Hemp_Industry.pdf

- Delele, M. A., Ngcobo, M. E. K., Opara, U. L., Pathare, P. B. (2013). Cfd modelling to study the effects of table grape packaging and stacking on fruit cooling and moisture loss. Acta Horticulturae, 1008, 105–112. https://doi.org/10.17660/actahortic.2013.1008.13

- Nalobina, O., Markova, O., Polishchuk, L. (2016). Zaprovadzhennia ta otsinka udoskonalenoi tekhnolohiyi otrymannia tresty lonu-dovhuntsia. Tekhniko-tekhnolohichni aspekty rozvytku ta vyprobuvannia novoi tekhniky i tekhnolohiy dlia silskoho hospodarstva Ukrainy, 20, 303–313. Available at: https://www.ndipvt.com.ua/oldsite/doc/zbirnik16.pdf

- Alemayehu, S., Abay, F., Ayimut, K. M., Assefa, D., Chala, A., Mahroof, R. et al. (2020). Evaluating different hermetic storage technologies to arrest mold growth, prevent mycotoxin accumulation and preserve germination quality of stored chickpea in Ethiopia. Journal of Stored Products Research, 85, 101526. https://doi.org/10.1016/j.jspr.2019.101526

- Lialina, N., Yudicheva, O., Samoilenko, A., Berezovskyi, Y., Moroz, O., Bondar-Pidhurska, O. et al. (2023). Evaluation of the quality of cellulose semi-finished products from technical hemp and the possibility of their further use. Fibres and Textiles, 30 (3), 48–54. https://doi.org/10.15240/tul/008/2023-3-006

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Viktor Sheichenko, Ivan Rogovskii, Yuliia Skoriak, Dmytro Petrachenko, Misha Shevchuk, Denys Sheichenko, Liudmyla Titova, Igor Sivak

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.