Assessing the impact of sewing machine thread take-up mechanism parameters on the magnitude and nature of thread take-up

DOI:

https://doi.org/10.15587/1729-4061.2024.315129Keywords:

sewing machine, chain stitch, thread take-up, thread take-up function, adjustment parametersAbstract

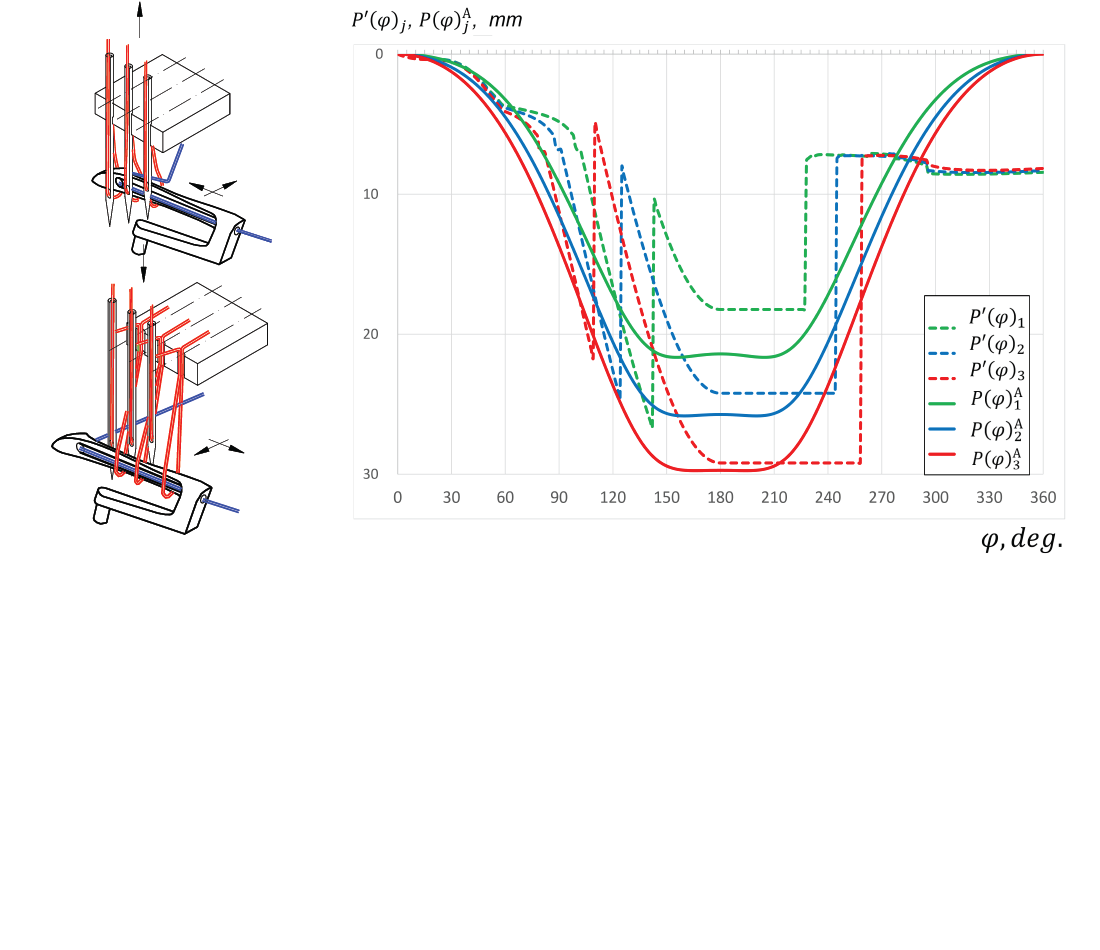

The subject of this study is the needle thread take-up mechanisms (NTТM) of modern chain stitch sewing machines of classes 400 and 600. The principal issue with these mechanisms is the complexity of their adjustment because of the large number of adjustable parameters and the need for clear recommendations for proper setup, which negatively affects their performance.

The research involved analyzing the impact of NTTM’s kinematic parameters and various thread path configurations in machines. The study revealed new patterns that allow for more precise thread take-up regulation, enabling better synchronization of the actual thread take-up with the required amount, thereby improving stitch quality and increasing sewing process productivity. Accurate thread take-up adjustment prevents excessive or insufficient thread tension, a common issue when sewing materials with variable thickness or stitch length.

The results can be used to adjust sewing machines and automate the tuning of technological processes by changing the adjustment parameters with variations in technological parameters. This is particularly important in producing 3D textile structures for reinforcing composite molds, where adjusting for average material thickness can cause thread tension issues when the current thickness changes. The practical application of these results will ensure stable sewing quality based on stitch parameters, which is relevant for automating machine settings and working with materials of varying thicknesses. The proposed recommendations will improve the manufacturing process and increase equipment efficiency

References

- Manoilenko, O. (2020). Topological analysis and synthesis of machine chain stitches. Fibres and Textiles, 4, 58–69. Available at: http://vat.ft.tul.cz/2020/4/VaT_2020_4_8.pdf

- Handbook of Analytical Methods for Textile Composites (1997). NTRS - NASA Technical Reports Server, 176. Available at: https://ntrs.nasa.gov/citations/19970017583

- Orlovskyi, B., Manoilenko, O. P., Bezuhlyi, D. (2023). Object-Oriented Analysis of Frame 3D Textile Structures. Journal of Engineering Sciences, 10 (2), C26–C35. https://doi.org/10.21272/jes.2023.10(2).c4

- Beloshenko, V., Voznyak, Y., Voznyak, A., Savchenko, B. (2017). New approach to production of fiber reinforced polymer hybrid composites. Composites Part B: Engineering, 112, 22–30. https://doi.org/10.1016/j.compositesb.2016.12.030

- Manoilenko, O., Нorobetc, V., Dvorzhak, V., Kovalov, Y., Kniaziev, I., Shkvyra, V. (2023). Research of variable parameters of needle thread take-up mechanisms and development of recommendations for adjusting multi-thread chain stitch sewing machines. Fibres and Textiles, 30 (5), 52–60. https://doi.org/10.15240/tul/008/2023-5-006

- Fristedt, T. (2012). Novel fiber placement technologies for composite applications. SPE ACE. Available at: https://www.tailoredfiberplacement.com/laystitch-acce-2012.pdfsept12,2012-с.8-14

- McDonnell, C., Hayes, S., Potluri, P. (2021). Investigation into the tensile properties of ISO-401 double-thread chain-stitched glass-fibre composites. International Journal of Lightweight Materials and Manufacture, 4 (2), 203–209. https://doi.org/10.1016/j.ijlmm.2020.11.001

- Lee, B., Herszberg, I., Bannister, M. K., Curiskis, J. I. (1997). The effect of weft binder path length on the architecture of multi-layer woven carbon preforms. Textile Composites and Characterisation, 5, 260–269.

- Wang, P., Legrand, X., Soulat, D. (2017). Three-Dimentional Textile Preform Using Advanced Textile Technologies for Composite Manufacturing. Textiles for Advanced Applications. https://doi.org/10.5772/intechopen.68175

- Boisse, P., Hamila, N., Vidal-Sallé, E., Dumont, F. (2011). Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses. Composites Science and Technology, 71 (5), 683–692. https://doi.org/10.1016/j.compscitech.2011.01.011

- Randima, L. M. L., Sandaranga, D. M. B. C., Jayawardana, T. S. S., Fernando, E. A. S. K. (2019). Design and Fabrication of an Automatic Tension Monitoring and Regulation System for Needle Thread. 2019 Moratuwa Engineering Research Conference (MERCon), 738–744. https://doi.org/10.1109/mercon.2019.8818866

- Rehman, A. ur, Rasheed, A., Javed, Z., Naeem, M. S., Ramzan, M. B., Karahan, M. (2021). Geometrical Model to Determine Sewing Thread Consumption for Stitch Class 406. Fibres and Textiles in Eastern Europe, 29 (6 (150)), 72–76. https://doi.org/10.5604/01.3001.0015.2726

- Malek, S., Khedher, F., Adolphe, D. C., Jaouachi, B. (2021). Sewing Thread Consumption for Chain Stitches of Class 400 using Geometrical and Multilinear Regression Models. Autex Research Journal, 21 (1), 52–62. https://doi.org/10.2478/aut-2019-0051

- Abeysooriya, R. P., Wickramasinghe, G. L. D. (2014). Regression model to predict thread consumption incorporating thread-tension constraint: study on lock-stitch 301 and chain-stitch 401. Fashion and Textiles, 1 (1). https://doi.org/10.1186/s40691-014-0014-5

- Rasheed, A., Ahmad, S., Ali, N., ur Rehman, A., Ramzan, M. B. (2018). Geometrical model to calculate the consumption of sewing thread for 504 over-edge stitch. The Journal of The Textile Institute, 109 (11), 1418–1423. https://doi.org/10.1080/00405000.2018.1423902

- Manoilenko, O. P., Gorobets, V. A., Dvorzhak, V. M., Pisarenko, D. D., Bylyk, K. A. (2023). Analytical inspection and development of a classification of needle threads teke-up mechanisms of chain stitch sewing machines. Technologies and Engineering, 4, 35–47. https://doi.org/10.30857/2786-5371.2022.4.3

- Manoilenko, O., Horobets, V., Kniaziev, I., Shkvyra, V. (2024). Development of classification of loop thread take-up mechanisms for chain stitch sewing machines based on their structural analysis. Technologies and Engineering, 5, 21–32. https://doi.org/10.30857/2786-5371.2023.5.2

- Safak, S., Şaka, Z., Özçelik, Z. (2012). Modification of the Classical Needle Bar and Thread Take-Up Lever Mechanism in Sewing Machines. Fibres and Textiles in Eastern Europe, 20 (4 (493)), 108–111. Available at: https://www.researchgate.net/publication/284142170

- Shcherban, V., Kolysko, O., Melnyk, G., Kolysko, M., Shcherban, Y., Shchutska, G. (2022). Determination of tension for aramid and carbon yarns while weaving industrial fabrics. Fibres and Textiles, 29 (1), 52–62. https://doi.org/10.15240/tul/008/2022-1-007

- Shcherban’, V. Yu., Kolysko, O., Melnyk, G., Kolysko, M., Halavska, L., Shcherban’, Yu. Yu. (2021). The influence of the curvature radius of the guiding surface on the tension of polyethylene and polyamide complex yarns during processing on weaving and knitting machines. Fibres and Textiles, 28 (3), 72–81. Available at: https://er.knutd.edu.ua/handle/123456789/18576

- Product introduction. Juki Corporation. Available at: https://www.juki.co.jp/en/products/

- Industrial sewing machine. PEGASUS CO. Available at: https://www.pegasus.co.jp/en/machine/

- PRODUCTS. Yamato Sewing Machine Mfg. Co., Ltd. Available at: https://www.yamato-sewing.com/en/product/

- Shcherban, V. Yu. (2018). Mekhanika nytky. Kyiv: TOV "Vydavnytstvo "Ukrblankovydav", 534. Available at: https://er.knutd.edu.ua/handle/123456789/9517

- Dvorzhak, V. M. (2016). Circuit simulation kinematic scheme of spatial four crank-rocker mechanisms of technological machines. Visnyk Kyivskoho natsionalnoho universytetu tekhnolohiy ta dyzainu, 2, 18–26. Available at: https://er.knutd.edu.ua/bitstream/123456789/1817/1/V96_P018-026.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Oleksandr Manoilenko, Volodymyr Dvorzhak, Vasyl Horobets, Igor Panasiuk, Dmytro Bezuhlyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.