Development of an extruded system with enhanced content of alpha-linolenic polyunsaturated fatty acid

DOI:

https://doi.org/10.15587/1729-4061.2024.315246Keywords:

extruded system, alpha-linolenic acid, flax seeds, barley groats, technological indicatorsAbstract

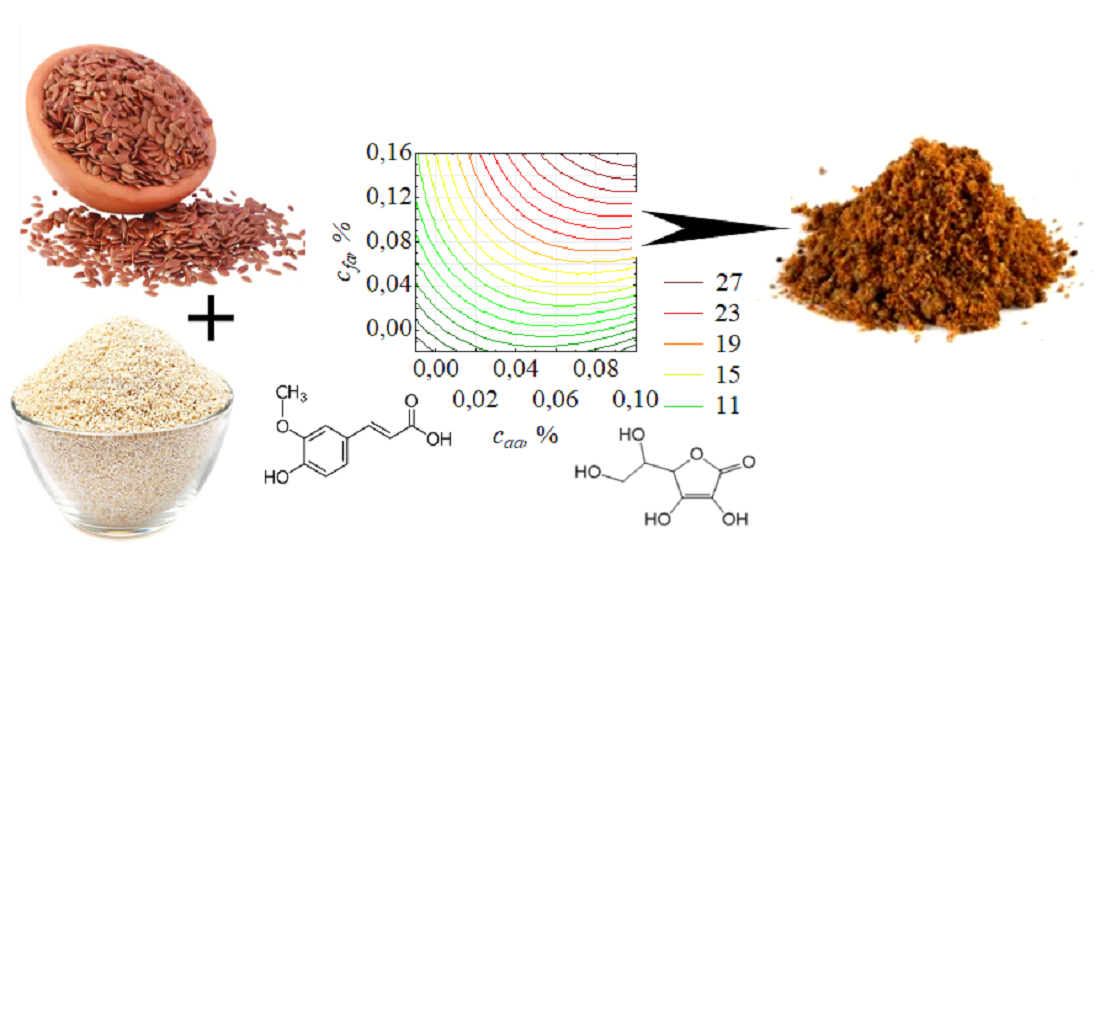

The object of the study is the dependence of the technological indicators of the extruded system with an increased ALA content on the composition of the raw materials. The problem of the study is the need to increase the oxidative stability of the lipid component of extrudates, preserve their nutritional value and improve technological characteristics (in particular, porosity). An extruded system with an increased content of alpha-linolenic polyunsaturated fatty acid (ALA) based on a mixture of barley groats and flax seeds has been developed. The influence of flaxseed content on the technological parameters of model extruded systems, in particular porosity and oxidative stability of the lipid component, was studied. It was found that the rational content of flax seeds in the extrusion mixture is 7.0 %, providing the necessary porosity (80 %) and the induction period of accelerated oxidation at a temperature of 80 °C (10 hours). The proposed technological approach makes it possible to increase the shelf life of products while preserving nutritional value. The developed extruded system is promising for further implementation in the food industry, which will contribute to expanding the range of extruded products and increasing their market competitiveness. The effect of antioxidants – ascorbic and ferulic acids on the oxidative stability of lipids of the extruded system was studied: the content of ascorbic acid – 0.06...0.09 %, the content of ferulic acid – 0.10...0.15 %. The lipid component of the extruded system of the developed composition demonstrates a high level of oxidative stability (oxidation induction period – up to 22 hours). The obtained results indicate the possibility of using extruded systems with an increased ALA content to create specialized products with extended shelf life and reduced raw material costs

References

- Banjac, V., Vukmirović, Đ., Pezo, L., Draganovic, V., Đuragić, O., Čolović, R. (2021). Impact of variability in protein content of sunflower meal on the extrusion process and physical quality of the extruded salmonid feed. Journal of Food Process Engineering, 44 (3). https://doi.org/10.1111/jfpe.13640

- Belinska, A., Bliznjuk, O., Shcherbak, O., Masalitina, N., Myronenko, L., Varankina, O. et al. (2022). Improvement of fatty systems biotechnological interesterification with immobilized enzyme preparation usage. Eastern-European Journal of Enterprise Technologies, 6 (6 (120)), 6–13. https://doi.org/10.15587/1729-4061.2022.268373

- Bajaj, S. R., Singhal, R. S. (2019). Effect of extrusion processing and hydrocolloids on the stability of added vitamin B12 and physico-functional properties of the fortified puffed extrudates. LWT, 101, 32–39. https://doi.org/10.1016/j.lwt.2018.11.011

- Zhang, B., Liu, G., Ying, D., Sanguansri, L., Augustin, M. A. (2017). Effect of extrusion conditions on the physico-chemical properties and in vitro protein digestibility of canola meal. Food Research International, 100, 658–664. https://doi.org/10.1016/j.foodres.2017.07.060

- Petik, I., Litvinenko, O., Kalyna, V., Ilinska, O., Raiko, V., Filenko, O. et al. (2023). Development of extruded animal feed based on fat and oil industry waste. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 112–120. https://doi.org/10.15587/1729-4061.2023.275509

- Belinska, A., Ryshchenko, I., Bliznjuk, O., Masalitina, N., Siedykh, K., Zolotarova, S. et al. (2024). Development of a method for inactivating lipoxygenases in linseed using chemical reagents. Technology Organic and Inorganic Substances, 4 (6 (130)), 14–21. https://doi.org/10.15587/1729-4061.2024.309079

- Singh, R., Sá, A. G. A., Sharma, S., Nadimi, M., Paliwal, J., House, J. D., Koksel, F. (2023). Effects of Feed Moisture Content on the Physical and Nutritional Quality Attributes of Sunflower Meal-based High-Moisture Meat Analogues. Food and Bioprocess Technology, 17 (7), 1897–1913. https://doi.org/10.1007/s11947-023-03225-8

- Flôres, I. G., Salles, C., Conti, A. C. (2024). Effects of the extrusion conditions, the addition of oil and the food matrix on the physical and sensory characteristics of pre-extrusion flavored products. Journal of Food Science and Technology, 61 (11), 2145–2156. https://doi.org/10.1007/s13197-024-05985-3

- Papchenko, V., Stepankova, G., Karatieieva, O., Balandina, I., Shapovalenko, D., Kariuk, A. et al. (2023). Determining the effect of raw materials moisture and lipid content on the technological properties of the extruded protein-fat system. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 37–46. https://doi.org/10.15587/1729-4061.2023.285132

- Petik, I., Litvinenko, O., Stankevych, S., Zabrodina, I., Ponomarova, M., Kotliar, O. et al. (2024). Determination of the cellulose- and lipid-containing components influence on the extrudate technological indicators. Eastern-European Journal of Enterprise Technologies, 2 (6 (128)), 6–13. https://doi.org/10.15587/1729-4061.2024.301843

- Gomes, K. S., Berwian, G. F., Batistella, V. M. C., Bender, L. E., Reinehr, C. O., Colla, L. M. (2022). Nutritional and Technological Aspects of the Production of Proteic Extruded Snacks Added of Novel Raw Materials. Food and Bioprocess Technology, 16 (2), 247–267. https://doi.org/10.1007/s11947-022-02887-0

- Leonard, W., Zhang, P., Ying, D., Fang, Z. (2019). Application of extrusion technology in plant food processing byproducts: An overview. Comprehensive Reviews in Food Science and Food Safety, 19 (1), 218–246. https://doi.org/10.1111/1541-4337.12514

- Tumuluru, J. S., Sokhansanj, S., Bandyopadhyay, S., Bawa, A. S. (2012). Changes in Moisture, Protein, and Fat Content of Fish and Rice Flour Coextrudates during Single-Screw Extrusion Cooking. Food and Bioprocess Technology, 6 (2), 403–415. https://doi.org/10.1007/s11947-011-0764-7

- Yousf, N., Nazir, F., Salim, R., Ahsan, H., Sirwal, A. (2017). Water solubility index and water absorption index of extruded product from rice and carrot blend. Journal of Pharmacognosy and Phytochemistry, 6 (6), 2165–2168. Available at: https://www.academia.edu/65515809

- Arêas, J. A. G., Rocha-Olivieri, C. M., Marques, M. R. (2016). Extrusion Cooking: Chemical and Nutritional Changes. Encyclopedia of Food and Health, 569–575. https://doi.org/10.1016/b978-0-12-384947-2.00266-x

- Belinska, A., Bochkarev, S., Varankina, O., Rudniev, V., Zviahintseva, O., Rudnieva, K. et al. (2019). Research on oxidative stability of protein-fat mixture based on sesame and flax seeds for use in halva technology. Eastern-European Journal of Enterprise Technologies, 5 (11 (101)), 6–14. https://doi.org/10.15587/1729-4061.2019.178908

- Papchenko, V., Matveeva, T., Bochkarev, S., Belinska, A., Kunitsia, E., Chernukha, A. et al. (2020). Development of amino acid balanced food systems based on wheat flour and oilseed meal. Eastern-European Journal of Enterprise Technologies, 3 (11 (105)), 66–76. https://doi.org/10.15587/1729-4061.2020.203664

- Vadukapuram, N., Hall, C., Tulbek, M., Niehaus, M. (2014). Physicochemical Properties of Flaxseed Fortified Extruded Bean Snack. International Journal of Food Science, 2014, 1–8. https://doi.org/10.1155/2014/478018

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Sergiy Bochkarev, Tetiana Chaika, Serhii Stankevych, Inna Zabrodina, Iryna Balandina, Larysa Obolentseva, Tetiana Сheremska, Myushfik Bakirov, Oleg Kolontaievskyi, Roman Voronov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.