Synthesis of polyethersulfone/titanium dioxide membranes: analysis of morphology, mechanical properties, and water filtration performance

DOI:

https://doi.org/10.15587/1729-4061.2024.316523Keywords:

antifouling, fabrication, filtration, membranes, permeability, polyethersulfone, titanium dioxideAbstract

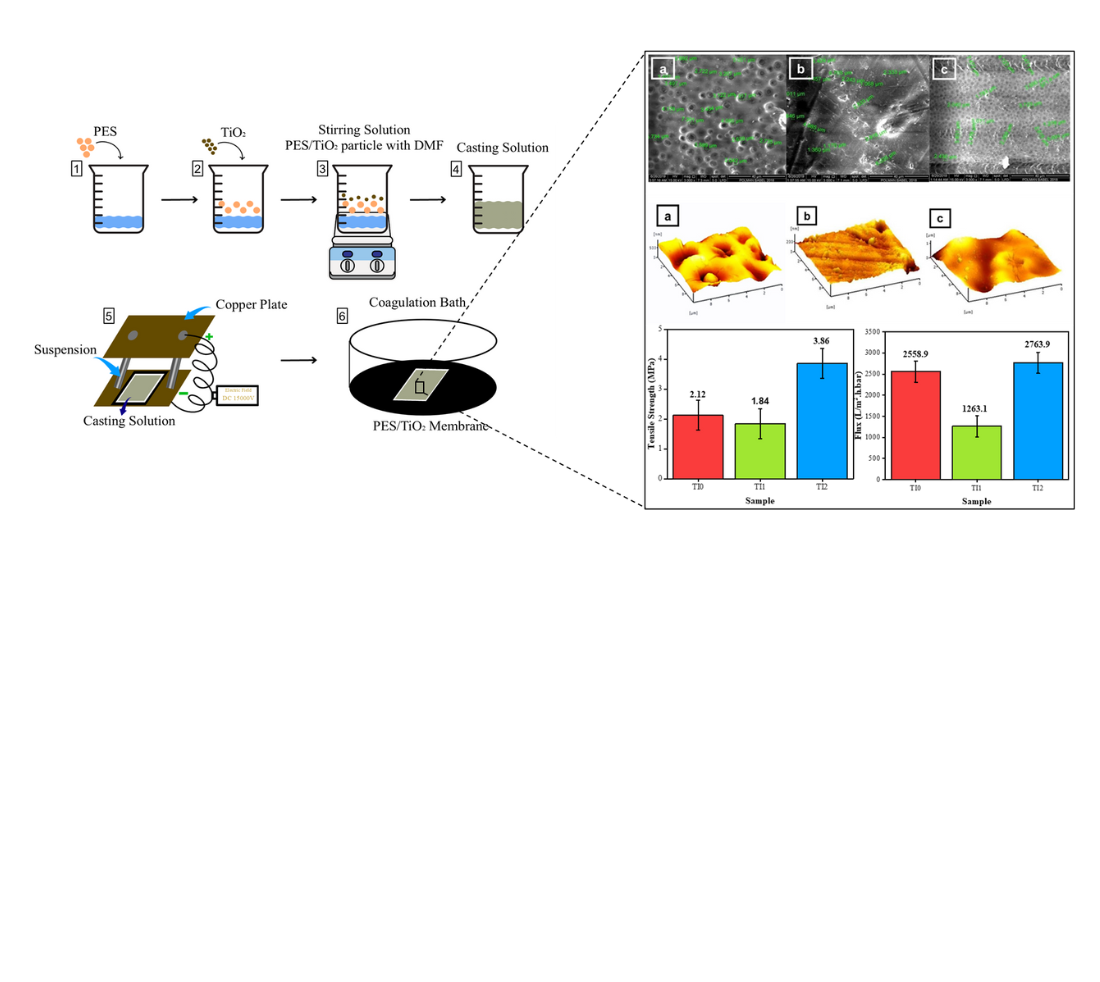

The increasing demand for clean water, driven by population growth, urbanization, and industrial activities, has led to significant challenges in public health, the economy, and the environment. Effective water purification technologies are essential to address this issue. This study explores using polyethersulfone (PES) polymer-based membranes reinforced with titanium dioxide (TiO2) nanoparticles for antifouling applications. The membranes were fabricated using an electric field treatment method. Scanning Electron Microscopy (SEM) revealed a pore size distribution between 1,170 μm and 7,122 μm, demonstrating that this method can be adjusted to create membranes with specific filtration characteristics. Atomic Force Microscope (AFM) analysis showed surface roughness between 150 and 500 nm, indicating that the membrane's surface morphology can be customized to improve performance. Mechanical testing showed that the tensile strength of the membranes varied with the addition of TiO2: the pure PES membrane (TI0) had a tensile strength of 2.12 MPa, while the TI1 membrane (20 % PES, 1 % TiO2) exhibited a decrease to 1.84 MPa. The TI2 membrane (30 % PES, 1 % TiO2) showed an increase in tensile strength to 3.86 MPa, confirming the reinforcing effect of TiO2 on the membrane's mechanical properties. Clean Water Permeability (CWP) testing indicated flux values of 2558.9 L/m2·h·bar for TI0, 1263.1 L/m2·h·bar for TI1, and 2763.9 L/m2·h·bar for TI2, highlighting the optimal balance of mechanical strength and permeability in TI2. The PES/TiO2 composite membrane, made using an electric field method, shows promise for water filtration due to its enhanced permeability, providing an efficient solution for water treatment

References

- Progress on drinking water, sanitation and hygiene 2000–2017. Special focus on inequalities (2019). UNICEF. Available at: https://www.unicef.org/reports/progress-on-drinking-water-sanitation-and-hygiene-2019

- Babaei, A. A., Reshadatian, N., Feizi, R. (2024). A state of the art-mini review on the sources, contamination, analysis, and consequences of microplastics in water. Results in Engineering, 23, 102827. https://doi.org/10.1016/j.rineng.2024.102827

- Kurniawan, T. A., Bandala, E. R., Othman, M. H. D., Goh, H. H., Anouzla, A., Chew, K. W. et al. (2024). Implications of climate change on water quality and sanitation in climate hotspot locations: A case study in Indonesia. Water Supply, 24 (2), 517–542. https://doi.org/10.2166/ws.2024.008

- Mousa, H. M., Fahmy, H. S., Ali, G. A. M., Abdelhamid, H. N., Ateia, M. (2022). Membranes for Oil/Water Separation: A Review. Advanced Materials Interfaces, 9 (27). https://doi.org/10.1002/admi.202200557

- Tomczak, W., Gryta, M. (2023). The Application of Polyethersulfone Ultrafiltration Membranes for Separation of Car Wash Wastewaters: Experiments and Modelling. Membranes, 13 (3), 321. https://doi.org/10.3390/membranes13030321

- Vafaei, K., Ashtiani, F. Z., Karimi, M., Ghorabi, S. (2023). Engineering hydrophobic surface on polyethersulfone membrane with bio‐inspired coating for desalination with direct contact membrane distillation. Polymers for Advanced Technologies, 34 (8), 2419–2436. https://doi.org/10.1002/pat.6061

- Anucha, C. B., Altin, I., Bacaksiz, E., Stathopoulos, V. N. (2022). Titanium dioxide (TiO₂)-based photocatalyst materials activity enhancement for contaminants of emerging concern (CECs) degradation: In the light of modification strategies. Chemical Engineering Journal Advances, 10, 100262. https://doi.org/10.1016/j.ceja.2022.100262

- Abed, I. A., Waisi, B. I. (2024). Performance Enhancement of Polyethersulfone-Based Ultrafiltration Membrane Decorated by Titanium Dioxide Nanoparticles for Dye Filtration. Ecological Engineering & Environmental Technology, 25 (5), 265–273. https://doi.org/10.12912/27197050/186182

- Ehsani, M., Aroujalian, A. (2019). Fabrication of electrospun polyethersulfone/titanium dioxide (PES/TiO2) composite nanofibers membrane and its application for photocatalytic degradation of phenol in aqueous solution. Polymers for Advanced Technologies, 31 (4), 772–785. https://doi.org/10.1002/pat.4813

- Ding, C., Qin, X., Tian, Y., Cheng, B. (2022). PES membrane surface modification via layer-by-layer self-assembly of GO@TiO2 for improved photocatalytic performance. Journal of Membrane Science, 659, 120789. https://doi.org/10.1016/j.memsci.2022.120789

- Yao, J., Shen, H., Gong, Y., Cheng, C. (2023). Preparation of a Cation Exchange Membrane by a Sol-Gel Method-Based Polyvinyl Alcohol to Improve Alkali Recovery via Diffusion Dialysis in the Textile Industry. Separations, 10 (7), 370. https://doi.org/10.3390/separations10070370

- Hu, W., Yang, X., Hou, X., Zhao, Q., Liu, B., Sun, Z. et al. (2020). Novel Nanocomposite PEM Membranes with Continuous Proton Transportation Channel and Reinforcing Network Formed by Electrospinning Solution Casting Method. Macromolecular Materials and Engineering, 305 (6). https://doi.org/10.1002/mame.201900388

- Saleem, J., Moghal, Z. K. B., Hafeez, A., Sajjad, S., Shoaib, M., Alahmad, J., McKay, G. (2024). Stretch-Induced Spin-Cast Membranes Based on Semi-Crystalline Polymers for Efficient Microfiltration. Polymers, 16 (13), 1799. https://doi.org/10.3390/polym16131799

- Barambu, N. U., Bilad, M. R., Bustam, M. A., Huda, N., Jaafar, J., Narkkun, T., Faungnawakij, K. (2020). Development of Polysulfone Membrane via Vapor-Induced Phase Separation for Oil/Water Emulsion Filtration. Polymers, 12 (11), 2519. https://doi.org/10.3390/polym12112519

- Fazal, M. R., Mataram, A. (2023). Polyvinylidene fluoride membranes with tin (IV) dioxide (SNo2) additives: enhancing water treatment for airport eco green. Journal of Airport Engineering Technology (JAET), 3 (2), 68–74. https://doi.org/10.52989/jaet.v3i2.100

- Pogharian, N., Vlahovska, P. M., Olvera de la Cruz, M. (2024). Effects of Normal and Lateral Electric Fields on Membrane Mechanical Properties. The Journal of Physical Chemistry B, 128 (38), 9172–9182. https://doi.org/10.1021/acs.jpcb.4c04255

- Ahmadi Bonakdar, M., Rodrigue, D. (2024). Electrospinning: Processes, Structures, and Materials. Macromol, 4 (1), 58–103. https://doi.org/10.3390/macromol4010004

- Du, M., Yang, J., Tao, Y., Xu, B., Gu, C., Zhao, H. et al. (2024). Experimental Study on the Agglomeration Behavior of Elongated Biomass Particles in a Lifting Tube. ACS Omega, 9 (4), 4931–4948. https://doi.org/10.1021/acsomega.3c08719

- Yap, Y. K., Oh, P. C., Chin, E. Y. J. (2021). Development of αFe2O3-TiO2/PPOdm Mixed Matrix Membrane for CO2/CH4 Separation. E3S Web of Conferences, 287, 02013. https://doi.org/10.1051/e3sconf/202128702013

- Meng, J., Zhong, J., Xiao, H., Ou, J. (2021). Interfacial design of nano-TiO2 modified fly ash-cement based low carbon composites. Construction and Building Materials, 270, 121470. https://doi.org/10.1016/j.conbuildmat.2020.121470

- Pradeepa, P., Edwinraj, S., Ramesh Prabhu, M. (2015). Effects of ceramic filler in poly(vinyl chloride)/poly(ethyl methacrylate) based polymer blend electrolytes. Chinese Chemical Letters, 26 (9), 1191–1196. https://doi.org/10.1016/j.cclet.2015.05.007

- Mataram, A., Anisya, N., Nadiyah, N. A., Afriansyah, A. (2020). Fabrication Membrane of Titanium dioxide (TiO2) Blended Polyethersulfone (PES) and Polyvinilidene fluoride (PVDF): Characterization, Mechanical Properties and Water Treatment. Key Engineering Materials, 867, 159–165. https://doi.org/10.4028/www.scientific.net/kem.867.159

- Li, C., Guo, X., Wang, X., Fan, S., Zhou, Q., Shao, H. et al. (2018). Membrane fouling mitigation by coupling applied electric field in membrane system: Configuration, mechanism and performance. Electrochimica Acta, 287, 124–134. https://doi.org/10.1016/j.electacta.2018.06.150

- Wang, X., Feng, M., Liu, Y., Deng, H., Lu, J. (2019). Fabrication of graphene oxide blended polyethersulfone membranes via phase inversion assisted by electric field for improved separation and antifouling performance. Journal of Membrane Science, 577, 41–50. https://doi.org/10.1016/j.memsci.2019.01.055

- Seyed Shahabadi, S. M., Rabiee, H., Seyedi, S. M., Mokhtare, A., Brant, J. A. (2017). Superhydrophobic dual layer functionalized titanium dioxide/polyvinylidene fluoride- co -hexafluoropropylene (TiO 2 /PH) nanofibrous membrane for high flux membrane distillation. Journal of Membrane Science, 537, 140–150. https://doi.org/10.1016/j.memsci.2017.05.039

- Zhao, F., Han, X., Shao, Z., Li, Z., Li, Z., Chen, D. (2022). Effects of different pore sizes on membrane fouling and their performance in algae harvesting. Journal of Membrane Science, 641, 119916. https://doi.org/10.1016/j.memsci.2021.119916

- García-Ivars, J., Corbatón-Báguena, M.-J., Iborra-Clar, M.-I. (2019). Development of Mixed Matrix Membranes: Incorporation of Metal Nanoparticles in Polymeric Membranes. Nanoscale Materials in Water Purification, 153–178. https://doi.org/10.1016/b978-0-12-813926-4.00011-2

- Zhang, H., Zuo, M., Zhang, X., Shi, X., Yang, L., Sun, S. et al. (2021). Effect of agglomeration on the selective distribution of nanoparticles in binary polymer blends. Composites Part A: Applied Science and Manufacturing, 149, 106590. https://doi.org/10.1016/j.compositesa.2021.106590

- Jaiswal, M., Dudhe, R., Sharma, P. K. (2014). Nanoemulsion: an advanced mode of drug delivery system. 3 Biotech, 5 (2), 123–127. https://doi.org/10.1007/s13205-014-0214-0

- Wasyłeczko, M., Wojciechowski, C., Chwojnowski, A. (2024). Polyethersulfone Polymer for Biomedical Applications and Biotechnology. International Journal of Molecular Sciences, 25 (8), 4233. https://doi.org/10.3390/ijms25084233

- Li, Z., Liu, M., Young, R. J. (2024). Dependence of the reinforcement of polymer-based nanocomposites upon the nanofiller geometry. Nano Materials Science. https://doi.org/10.1016/j.nanoms.2024.04.014

- Ravandi, R., Zeinali Heris, S., Hemmati, S., Aghazadeh, M., Davaran, S., Abdyazdani, N. (2024). Effects of chitosan and TiO2 nanoparticles on the antibacterial property and ability to self-healing of cracks and retrieve mechanical characteristics of dental composites. Heliyon, 10 (6), e27734. https://doi.org/10.1016/j.heliyon.2024.e27734

- Batool, M., Shafeeq, A., Haider, B., Ahmad, N. M. (2021). TiO2 Nanoparticle Filler-Based Mixed-Matrix PES/CA Nanofiltration Membranes for Enhanced Desalination. Membranes, 11 (6), 433. https://doi.org/10.3390/membranes11060433

- Sunar, T., Parenti, P., Tunçay, T., Özyürek, D., Annoni, M. (2023). The Effects of Nanoparticle Reinforcement on the Micromilling Process of A356/Al2O3 Nanocomposites. Journal of Manufacturing and Materials Processing, 7 (4), 125. https://doi.org/10.3390/jmmp7040125

- Karim, S. S., Farrukh, S., Hussain, A., Younas, M., Noor, T. (2022). The influence of polymer concentration on the morphology and mechanical properties of asymmetric polyvinyl alcohol (PVA) membrane for O2/N2 separation. Polymers and Polymer Composites, 30. https://doi.org/10.1177/09673911221090053

- Bilal, A., Yasin, M., Akhtar, F., Gilani, M., Almohamadi, H., Younas, M. et al. (2024). Enhancing Water Purification by Integrating Titanium Dioxide Nanotubes into Polyethersulfone Membranes for Improved Hydrophilicity and Anti-Fouling Performance. Membranes, 14 (5), 116. https://doi.org/10.3390/membranes14050116

- Yi, P., Jia, H., Yang, X., Fan, Y., Xu, S., Li, J. et al. (2023). Anti-biofouling properties of TiO2 coating with coupled effect of photocatalysis and microstructure. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 656, 130357. https://doi.org/10.1016/j.colsurfa.2022.130357

- Rudakova, A. V., Emeline, A. V., Romanychev, A. I., Bahnemann, D. W. (2021). Photoinduced hydrophilic behavior of TiO2 thin film on Si substrate. Journal of Alloys and Compounds, 872, 159746. https://doi.org/10.1016/j.jallcom.2021.159746

- Cai, W., Chen, H., Lin, J., Liu, Y., Wu, F., Pu, X. (2023). Inorganic nanoparticles-modified polyvinyl chloride separation membrane and enhanced anti-fouling performance. Surfaces and Interfaces, 38, 102885. https://doi.org/10.1016/j.surfin.2023.102885

- Deng, H., Lei, H., Luo, Y., Huan, C., Li, J., Li, H. et al. (2024). The effects of titanium dioxide nanoparticles on cadmium bioaccumulation in ramie and its application in remediation of cadmium-contaminated soil. Alexandria Engineering Journal, 86, 663–668. https://doi.org/10.1016/j.aej.2023.12.019

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Agung Mataram, Aneka Firdaus, Muhammad Yanis, Rahma Dani, Subriyer Nasir, Ahmad Fauzi Ismail, Mohd Hafiz Dzarfan Othman

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.